Abstract

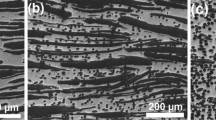

The optimization of metal–matrix composite material is linked firstly with the intrinsic properties of the matrix and the reinforcement used and secondly with the reinforcement–matrix interfacial zone and the distribution/orientation of the reinforcement inside the metal–matrix. Flake powder metallurgy was used to fabricate graphite flake reinforced aluminum matrix (Al/GF) composites fabricated by vacuum hot pressing. Two types of aluminum powders morphology were used: spherical (AlS) and flake (AlF) powders. A higher thermal conductivity in the in-plane direction of the graphite flakes was obtained for Al/GF composite materials fabricated with aluminum flake powder. In addition to a better orientation of the GF in the flake aluminum matrix, a 3D puckered surface and plane surface are formed at the Al/GF interface in, respectively, AlS/GF and AlF/GF composite materials. Due to the morphology incompatibility between the graphite flakes and the spherical powder, the damaged inner structure of GF contributes to a limited enhancement of thermal conductivity in AlS/GF composite materials.

Similar content being viewed by others

References

Zweben C (1998) Advances in composite materials for thermal management in electronic packaging. JOM 50(6):47–51

Zweben C (2005) Ultrahigh-thermal-conductivity packaging materials. In: Annual IEEE semiconductor thermal measurement and management symposium, pp 168–174

Rohatgi PK (1993) Metal–matrix composites. Defence Sci J 43(4):323–349

Mallik S, Ekere N, Best C, Bhatti R (2011) Investigation of thermal management materials for automotive electronic control units. Appl Therm Eng 31(2–3):355–362

Yoshida K, Morigami H (2004) Thermal properties of diamond/copper composite material. Microelectron Reliab 44(2):303–308

Ruch PW, Beffort O, Kleiner S, Weber L, Uggowitzer PJ (2006) Selective interfacial bonding in Al(Si)-diamond composites and its effect on thermal conductivity. Compos Sci Technol 66(15):2677–2685

Beffort O, Khalid FA, Weber L, Ruch P, Klotz UE, Meier S, Kleiner S (2006) Interface formation in infiltrated Al(Si)/diamond composites. Diam Relat Mater 15(9):1250–1260

Kurita H, Feuillet E, Guillemet T, Heintz J-M, Kawasaki A, Silvain J-F (2014) Simple fabrication and characterization of discontinuous carbon fiber reinforced aluminum matrix composite for lightweight heat sink applications. Acta Metall Sin (English Lett) 27(4):714–722

Pierson HO (1993) Handbook of carbon, graphite, diamond and fullerenes. Noyes Publications, Park Ridge, pp 194–195

Chen JK, Huang IS (2013) Thermal properties of aluminum-graphite composites by powder metallurgy. Compos Part B Eng 44(1):698–703

Murakami M, Nishiki N, Nakamura K, Ehara J, Okada H, Kouzaki T, Watanabe K et al (1992) Yoshimura, S. High-quality and highly oriented graphite block from polycondensation polymer films. Carbon 30(2):255–262

Klemens PG, Pedraza DF (1994) Thermal conductivity of graphite in the basal plane. Carbon 32(4):735–741

Fu Q, Yang J, Chen Y, Li D, Xu D (2015) Experimental evidence of very long intrinsic phonon mean free path along the c-axis of graphite. Appl Phys Lett 106(3):031905

Huang Y, Su Y, Li S, Ouyang Q, Zhang G, Zhang L, Zhang D (2016) Fabrication of graphite film/aluminum composites by vacuum hot pressing: process optimization and thermal conductivity. Compos B Eng 107:43–50

Tao P, Shang W, Song C, Shen Q, Zhang F, Luo Z, Yi N, Zhang D, Deng T (2015) Bioinspired engineering of thermal materials. Adv Mater 27(3):428–463

Metzler RA, Abrecht M, Olabisi RM, Ariosa D, Johnson CJ, Frazer BH, Coppersmith SN et al (2007) Architecture of columnar nacre, and implications for its formation mechanism. Phys Rev Lett 98(26):268102

Rousseau M, Lopez E, Stempflé P, Brendlé M, Franke L, Guette A, Naslain R et al (2005) Multiscale structure of sheet nacre. Biomaterials 26(31):6254–6262

Fan G, Xu R, Tan Z, Zhang D, Li Z (2014) Development of flake powder metallurgy in fabricating metal–matrix composites: a review. Acta Metall Sin (English Lett) 27(5):806–815

Jiang L, Fan G, Li Z, Kai X, Zhang D, Chen Z, Humphries S et al (2011) An approach to the uniform dispersion of a high volume fraction of carbon nanotubes in aluminum powder. Carbon 49(6):1965–1971

Jiang L, Li Z, Fan G, Cao L, Zhang D (2012) The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 50(5):1993–1998

Jiang L, Li Z, Fan G, Cao L, Zhang D (2012) Strong and ductile carbon nanotube/aluminum bulk nanolaminated composites with two-dimensional alignment of carbon nanotubes. Scr Mater 66(6):331–334

Jiang L, Li Z, Fan G, Zhang D (2011) A flake powder metallurgy approach to Al2O3/Al biomimetic nanolaminated composites with enhanced ductility. Scr Mater 65(5):412–415

Li Z, Guo Q, Li Z, Fan G, Xiong D-B, Su Y, Zhang J et al (2015) Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure. Nano Lett. 15(12):8077–8083

Weber L, Tavangar R (2007) On the influence of active element content on the thermal conductivity and thermal expansion of Cu–X (X = Cr, B) diamond composites. Scr Mater 57(11):988–991

Azina C, Roger J, Joulain A, Mauchamp V, Mortaigne B, Lu YF, Silvain J-F (2018) Solid-liquid co-existent phase process: towards fully dense and thermally efficient Cu/C composite materials. J Alloy Compd 738:292–300

Molina JM, Louis E (2015) Anisotropy in thermal conductivity of graphite flakes-SiCp/matrix composites: implications in heat sinking design for thermal management applications. Mater Charact 109:107–115

Zhou C, Huang W, Chen Z, Ji G, Wang ML, Chen D, Wang HW (2015) In-plane thermal enhancement behaviors of Al matrix composites with oriented graphite flake alignment. Compos B Eng 70:256–262

Li W, Liu Y, Wu G (2015) Preparation of graphite flakes/Al with preferred orientation and high thermal conductivity by squeeze casting. Carbon 95:545–551

Prieto R, Molina JM, Narciso J, Louis E (2011) Thermal conductivity of graphite flakes-SiC particles/metal composites. Compos Part A Appl Sci Manuf 42(12):1970–1977

Kurita H, Miyazaki T, Kawasaki A, Lu Y, Silvain J-F (2015) Interfacial microstructure of graphite flake reinforced aluminum matrix composites fabricated via hot pressing. Compos A Appl Sci Manuf 73:125–131

Oddone V, Boerner B, Reich S (2017) Composites of aluminum alloy and magnesium alloy with graphite showing low thermal expansion and high specific thermal conductivity. Sci Technol Adv Mater 18(1):180–186

Liu Q, He X-B, Ren S-B, Zhang C, Ting-Ting L, Qu X-H (2014) Thermophysical properties and microstructure of graphite flake/copper composites processed by electroless copper coating. J Alloy Compd 587:255–259

Chen J, Ren S, He X, Qu X (2017) Properties and microstructure of nickel-coated graphite flakes/copper composites fabricated by spark plasma sintering. Carbon 121:25–34

Seldin EJ (1966) Stress–strain properties of polycrystalline graphites in tension and compression at room temperature. Carbon 4(2):177–191

Hasani S, Panjepour M, Shamanian M (2012) The oxidation mechanism of pure aluminum powder particles. Oxid Metals 78(3–4):179–195

Levin I, Brandon D (1998) Metastable alumina polymorphs: crystal structures and transition sequences. J Am Ceram Soc 81(8):1995–2012

Vidano RP, Fischbach DB, Willis LJ, Loehr TM (1981) Observation of Raman band shifting with excitation wavelength for carbons and graphites. Solid State Commun 39(2):341–344

Tuinstra F, Koenig JL (1970) Raman spectrum of graphite. J Chem Phys 53(3):1126–1130

Pimenta MA, Dresselhaus G, Dresselhaus MS, Cançado LG, Jorio A, Saito R (2007) Studying disorder in graphite-based systems by Raman spectroscopy. Phys Chem Chem Phys 9(11):1276–1291

Ho CY, Powell RW, Liley PE (1972) Thermal conductivity of the elements. J Phys Chem Ref Data 1(2):279–421

Nan C-W, Birringer R, Clarke DR, Gleiter H (1997) Effective thermal conductivity of particulate composites with interfacial thermal resistance. J Appl Phys 81(10):6692–6699

Ren S, Chen J, He X, Qu X (2018) Effect of matrix-alloying-element chromium on the microstructure and properties of graphite flakes/copper composites fabricated by hot pressing sintering. Carbon 127:412–423

Molina JM, Prieto R, Narciso J, Louis E (2009) The effect of porosity on the thermal conductivity of Al-12 wt% Si/SiC composites. Scr Mater 60(7):582–585

Prasher R (2008) Thermal boundary resistance and thermal conductivity of multiwalled carbon nanotubes. Phys Rev B Condens Matter Mater Phys 77(7):075424

Swartz ET, Pohl RO (1989) Thermal boundary resistance. Rev Mod Phys 61(3):605–668

Acknowledgements

This work was funded by the University of Bordeaux (2015-FD-24).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chamroune, N., Mereib, D., Delange, F. et al. Effect of flake powder metallurgy on thermal conductivity of graphite flakes reinforced aluminum matrix composites. J Mater Sci 53, 8180–8192 (2018). https://doi.org/10.1007/s10853-018-2139-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2139-1