Abstract

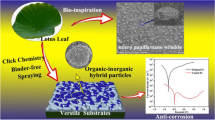

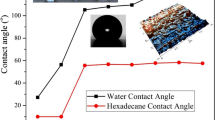

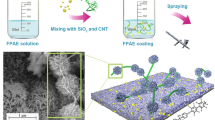

A corrosion-resistant superhydrophobic and superoleophilic modified poly(vinylidene fluoride)-based bulk material with oil–water separation ability is fabricated through a facile method of molding and sintering process. Fluorinated ethylene propylene was added as the one of the cross-linking agents. Nanometer silica (SiO2) and carbon nanotubes (CNTs) were added into the bulk material to construct the necessary reticulate papillae structures for superhydrophobic surface. NH4HCO3 was added as a pore-forming reagent in order to realize porous structure and oil–water separation. The bulk material can be designed to different appearances, such as cuboids, cylinder and sealing rings. The resulting bulk material shows excellent superhydrophobic and superoleophilic with a water contact angle of 164° and oil contact angle of almost 0°. As the SiO2 and CNTs filled the entire bulk material, any section of the bulk material shows excellent superhydrophobicity. The thermal resistance of the bulk material was improved due to the introduction of nanoparticles. The corrosion resistance of the superhydrophobic bulk material was investigated in an aqueous NaCl solution (3.5%). The results show that the prepared composite bulk material is effective in corrosion resistance, primarily due to the barrier effect of Cassie–Baxter model of superhydrophobic surface. It is believed that this bulk material would be an engineering material for large-scale application.

Similar content being viewed by others

References

Xue Z, Cao Y, Liu N et al (2014) Special wettable materials for oil/water separation. J Mater Chem A 2(8):2445–2460

Wang B, Liang W, Guo Z et al (2015) Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature. Chem Soc Rev 44(1):336–361

Chu Z, Feng Y, Seeger S (2015) Oil/water separation with selective superantiwetting/superwetting surface materials. Angew Chem Int Ed 54(8):2328–2338

Wang H, Wang E, Liu Z et al (2015) A novel carbon nanotubes reinforced superhydrophobic and superoleophilic polyurethane sponge for selective oil–water separation through a chemical fabrication. J Mater Chem A 3(1):266–273

Ge J, Ye YD, Yao HB et al (2014) Pumping through porous hydrophobic/oleophilic materials: an alternative technology for oil spill remediation. Angew Chem 126(14):3686–3690

Li B, Li L, Wu L et al (2014) Durable superhydrophobic/superoleophilic polyurethane sponges inspired by mussel and lotus leaf for the selective removal of organic pollutants from water. ChemPlusChem 79(6):850–856

Zhang X, Li Z, Liu K et al (2013) Bioinspired multifunctional foam with self-cleaning and oil/water separation. Adv Funct Mater 23(22):2881–2886

Zhu Q, Chu Y, Wang Z et al (2013) Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material. J Mater Chem A 1(17):5386–5393

Choi SJ, Kwon TH, Im H et al (2011) A polydimethylsiloxane (PDMS) sponge for the selective absorption of oil from water. ACS Appl Mater Interfaces 3(12):4552–4556

Wang E, Wang H, Liu Z et al (2015) One-step fabrication of a nickel foam-based superhydrophobic and superoleophilic box for continuous oil–water separation. J Mater Sci 50(13):4707–4716. doi:10.1007/s10853-015-9021-1

Feng L, Zhang Z, Mai Z et al (2004) A super-hydrophobic and super-oleophilic coating mesh film for the separation of oil and water. Angew Chem Int Ed 43(15):2012–2014

Lee CH, Johnson N, Drelich J et al (2011) The performance of superhydrophobic and superoleophilic carbon nanotube meshes in water–oil filtration. Carbon 49(2):669–676

Crick CR, Gibbins JA, Parkin IP (2013) Superhydrophobic polymer-coated copper-mesh; membranes for highly efficient oil–water separation. J Mater Chem A 1(19):5943–5948

Wang B, Li J, Wang G et al (2013) Methodology for robust superhydrophobic fabrics and sponges from in situ growth of transition metal/metal oxide nanocrystals with thiol modification and their applications in oil/water separation. ACS Appl Mater Interfaces 5(5):1827–1839

Li K, Zeng X, Li H et al (2014) Facile fabrication of superhydrophobic filtration fabric with honeycomb structures for the separation of water and oil. Mater Lett 120:255–258

Zhu X, Zhang Z, Ge B et al (2014) A versatile approach to produce superhydrophobic materials used for oil–water separation. J Colloid Interface Sci 432:105–108

Zhang J, Seeger S (2011) Polyester materials with superwetting silicone nanofilaments for oil/water separation and selective oil absorption. Adv Funct Mater 21(24):4699–4704

Stachowiak G, Batchelor AW (2013) Engineering tribology. Butterworth-Heinemann, Oxford

Zang Z, Nakamura A, Temmyo J (2013) Single cuprous oxide films synthesized by radical oxidation at low temperature for PV application. Opt Express 21(9):11448–11456

Zhu X, Zhang Z, Ren G et al (2012) A novel superhydrophobic bulk material. J Mater Chem 22(38):20146–20148

Ge B, Zhang Z, Zhu X et al (2013) A magnetically superhydrophobic bulk material for oil removal. Colloids Surf A 429:129–133

Zhang X, Guo Y, Chen H et al (2014) A novel damage-tolerant superhydrophobic and superoleophilic material. J Mater Chem A 2(24):9002–9006

Peng QY, Cong PH, Liu XJ et al (2009) The preparation of PVDF/clay nanocomposites and the investigation of their tribological properties. Wear 266(7):713–720

Thangavel E, Ramasundaram S, Pitchaimuthu S et al (2014) Structural and tribological characteristics of poly (vinylidene fluoride)/functionalized graphene oxide nanocomposite thin films. Compos Sci Technol 90:187–192

Liang S, Kang Y, Tiraferri A et al (2013) Highly hydrophilic polyvinylidene fluoride (PVDF) ultrafiltration membranes via postfabrication grafting of surface-tailored silica nanoparticles. ACS Appl Mater Interfaces 5(14):6694–6703

Shi Y, Xiao X (2016) Facile spray-coating for fabrication of superhydrophobic SiO2/PVDF nanocomposite coating on paper surface. J Dispers Sci Technol 37(5):640–645

Sahoo BN, Balasubramanian K (2015) A nanocellular PVDF–graphite water-repellent composite coating. RSC Adv 5(9):6743–6751

Wang H, Liu Z, Wang E et al (2015) A robust superhydrophobic PVDF composite coating with wear/corrosion-resistance properties. Appl Surf Sci 332:518–524

Wang H, Gao D, Meng Y et al (2015) Corrosion-resistance, robust and wear-durable highly amphiphobic polymer based composite coating via a simple spraying approach. Prog Org Coat 82:74–80

Ross G, Watts J, Hill M, Morrissey P (2000) Surface modification of poly(vinylidenefluoride) by alkaline treatment. 1. The degradation mechanism. Polymer 41:1685–1696

Accardo A, Shalabaeva V, Cola ED et al (2015) Superhydrophobic surfaces boost fibril self-assembly of amyloid β peptides. Acs Appl Mater Interfaces 7(37):20875–20884

Accardo A, Trevisiol E, Cerf A et al (2016) Versatile multicharacterization platform involving tailored superhydrophobic SU-8 micropillars for the investigation of breast cancer estrogen receptor isoforms. J Vac Sci Technol B 34:06K201

Zhang G, Schlarb AK, Tria S et al (2008) Tensile and tribological behaviors of PEEK/nano-SiO2 composites compounded using a ball milling technique. Compos Sci Technol 68(15):3073–3080

Acknowledgements

The research is financially supported by the National Young Top Talents Plan of China (2013042), National Science Foundation of China (Grant Nos. 21676052, 21606042) and the Science Foundation for Distinguished Young Scholars of Heilongjiang Province (JC201403), Graduate Student Innovation Project of Northeast Petroleum University (YJSCX2014-021NEPU).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, E., Wang, H., Hu, Y. et al. Corrosion-resistant engineering superhydrophobic and superoleophilic bulk materials with oil–water separation property. J Mater Sci 52, 7130–7139 (2017). https://doi.org/10.1007/s10853-017-0948-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0948-2