Abstract

Multiwalled carbon nanotube (MWCNT)/silicon carbide (SiC) composites were fabricated by spark plasma sintering at 2000 °C under 50 MPa for 10 min in Argon. Physical properties and Williamson–Hall analyses of X-ray diffraction patterns indicated strong influence of CNT on densification, crystallite size, and lattice micro-strain of pure SiC. Structural retention of CNTs, CNT/SiC interactions, and formation of 3–4 nm thick interface in sintered composites were confirmed through electron microscopy. Meyer’s exponent (1.84–1.89) of hardness data indicated almost similar indentation size effect in the studied specimens. Modified proportional specimen resistance model revealed formation of compressive surface residual stress and enhanced elastic response in CNT/SiC composites compared to pure SiC. R-curve sensitivity of present composites (toughening exponent, n ranged from 0.231 to 0.247) was found to be much improved than that obtained for pure SiC (n = 0.155). The 0.3 wt% MWCNT/SiC composite offered the highest toughness (3.93–5.56 MPa-m0.5) within the investigated loading range which was 17–31 % higher than those of monolithic SiC. Present composites also offered much better wear resistance up to 20 N. Wear rate of 0.1 wt% CNT/SiC composite was found to be more than 47 % lower than that obtained for pure SiC. At the highest CNT loading i.e., 1.2 wt%, composite also showed 10–12 % reduction in friction coefficient (μ) over monolithic SiC (μ = 0.53–0.58) due to the self-lubrication ability of CNT.

Similar content being viewed by others

References

Munro RG (1997) Material properties of a sintered α-SiC. J Phys Chem-US 26:1195–1203

Izhevskyi VA, Genova LA, Bressiani JC et al. (2000) Review article: silicon carbide. Structure, properties and processing. Cerâmica 46:4–13

Casady JB, Johnson RW (1996) Status of silicon carbide (SiC) as a wide-bandgap semiconductor for high-temperature applications: a review. Solid State Electron 39:1409–1422

Nava F, Bertuccio G, Cavallini A et al. (2008) Silicon carbide and its use as a radiation detector material. Meas Sci Technol 19:1–25

Willander M, Friesel M, Wahab Q-U et al. (2006) Silicon carbide and diamond for high temperature device applications. J Mater Sci 17:1–25. doi:10.1007/s10854-005-5137-4

Lafon-Placette S, Delbé K, Denape J et al. (2015) Tribological characterization of silicon carbide and carbon materials. J Eur Ceram Soc 35:1147–1159

Hayun S, Paris V, Mitrani R et al. (2012) Microstructure and mechanical properties of silicon carbide processed by spark plasma sintering (SPS). Ceram Int 38:6335–6340

Kamalakaran R, Lupo F, Grobert N et al. (2004) Microstructural characterization of C–SiC–carbon nanotube composite flakes. Carbon 42:1–4

Song N, Liu H, Fang J-Z (2015) Fabrication and mechanical properties of multi-walled carbon nanotube reinforced reaction bonded silicon carbide composites. Ceram Int 42:351–356

Morisada Y, Miyamoto Y, Takaura Y et al. (2007) Mechanical properties of SiC composites incorporating SiC-coated multi-walled carbon nanotubes. Int J Refract Metals Hard Mater 25:322–327

Kim S, Kriven WM (1997) Preparation, microstructure, and mechanical properties of silicon carbide-dysprosia composites. J Am Ceram Soc 80:2997–3008

Cho D-H, Kim Y-W, Kim W (1997) Strength and fracture toughness of in situ-toughened silicon carbide. J Mater Sci 32:4777–4782. doi:10.1023/A:1018635131661

Yuan R, Kruzic JJ, Zhang XF et al. (2003) Ambient to high-temperature fracture toughness and cyclic fatigue behavior in Al-containing silicon carbide ceramics. Acta Mater 51:6477–6491

Shimoda K, Hinoki T, Kishimoto H et al. (2011) Enchanced high-temperature performances of SiC/SiC composites by high densification and crystalline structure. Compos Sci Technol 71:326–332

Yang B, Zhou X, Chai Y (2015) Mechanical properties of SiCf/SiC composites with PyC and the BN interface. Ceram Int 41:7185–7190

Raju K, Yu H-W, Park J-Y et al. (2015) Fabrication of SiCf/SiC composites by alternating current electrophoretic deposition (AC–EPD) and hot pressing. J Eur Ceram Soc 35:503–511

Ma RZ, Wu J, Wei BQ et al. (1998) Processing and properties of carbon nanotubes–nano-SiC ceramic. J Mater Sci 33:5243–5246. doi:10.1023/A:1004492106337

Hu Z, Dong S, Hu J et al. (2013) Fabrication and properties analysis of Cf–CNT/SiC composite. Ceram Int 39:2147–2152

H-z Wang, X-d Li, Ma J et al. (2012) Fabrication of multi-walled carbon nanotube-reinforced carbon fiber/silicon carbide composites by polymer infiltration and pyrolysis process. Compos Sci Technol 72:461–466

Novak S, Ivekovic A (2013) SiC–CNT composite prepared by electrophoretic codeposition and the polymer infiltration and pyrolysis process. J Phys Chem B 117:1680–1685

Clark MD, Walker LS, Hadjiev VG et al. (2012) Polymer precursor-based preparation of carbon nanotube-silicon carbide nanocomposites. J Am Ceram Soc 95:328–337

Wang Y, Iqbal Z, Mitra S (2006) Rapid, low temperature microwave synthesis of novel carbon nanotube–silicon carbide composite. Carbon 44:2804–2808

Wang Y, Voronin GA, Zerda TW et al. (2006) SiC–CNT nanocomposites: high pressure reaction synthesis and characterization. J Phys 18:275–282

Lü ZH, Jiang DL, Zhang JX et al. (2009) Preparation and properties of multi-wall carbon nanotube/SiC composites by aqueous tape casting. Sci China Ser 52:132–136

Gu Z, Yang Y, Li K et al. (2011) Aligned carbon nanotube-reinforced silicon carbide composites produced by chemical vapor infiltration. Carbon 49:2475–2482

Jiang D, Zhang J, Lv Z (2012) Multi-wall carbon nanotubes (MWCNTs)–SiC composites by laminated technology. J Eur Ceram Soc 32:1419–1425

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall Mater 1:22–31

Saeedifar Z, Nourbakhsh AA, Kalbasi RJ et al. (2013) Low-temperature magnesiothermic synthesis of mesoporous silicon carbide from an MCM-48/polyacrylamide nanocomposite precursor. J Mater Sci Technol 29:255–260

Sarkar S, Das PK (2012) Temperature and load dependent mechanical properties of pressureless sintered carbon nanotube/alumina nanocomposites. Mater Sci Eng A 531:61–69

Wade J, Wu H (eds) (2013) Hardness of alumina/silicon carbide nanocomposites at various silicon carbide volume percentages. Wiley, Hoboken

Wade J, Ghosh S, Claydon P et al. (2015) Contact damage of silicon carbide ceramics with different grain structures measured by Hertzian and Vickers indentation. J Eur Ceram Soc 35:1725–1736

Niihara K, Morena R, Hasselman DPH (1982) Evaluation of K1C of Brittle solids by the indentation method with low-crack-to-indent ratios. J Mater Sci Lett 1:13–16

Yadhukulakrishnan GB, Rahman A, Karumuri S et al. (2012) Spark plasma sintering of silicon carbide and multi-walled carbon nanotube reinforced zirconium diboride ceramic composite. Mater Sci Eng A 552:125–133

Tomaszewski H, Boniecki M, Weglarz H (2000) Effect of grain size on R-curve behaviour of alumina ceramics. J Eur Ceram Soc 20:2569–2574

Deng Z-Y, Kobayashi T (1999) Microstructure and R-curve behavior of Al2O3-SiC ceramic matrix composites. J Mater Sci Lett 18:489–492

Ramachandran N, Shetty DK (1991) Rising crack-growth-resistance (R-curve) behavior of toughened alumina and silicon nitride. J Am Ceram Soc 74:2634–2641

Mukhopadhyay AK, Chakraborty D, Swain MV et al. (1997) Scratch deformation behaviour of alumina under a sharp indenter. J Eur Ceram Soc 17:91–100

Melk L, Rovira JJR, Antti M-L et al. (2015) Coefficient of friction and wear resistance of zirconia–MWCNTs composites. Ceram Int 41:459–468

Kim S-H, Lee SW (2014) Wear and friction behavior of self-lubricating alumina–zirconia–fluoride composites fabricated by the PECS technique. Ceram Int 40:779–790

Sarkar S, Das PK (2014) Dry sliding wear characteristics of carbon nanotube/alumina nanocomposites under a sharp pyramidal indenter. Ceram Int 40:13971–13978

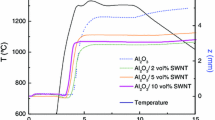

Morales-Rodríguez A, Gallardo-López A, Fernández–Serrano A et al. (2014) Improvement of Vickers hardness measurement on SWNT/Al2O3 composites consolidated by spark plasma sintering. J Eur Ceram Soc 34:3801–3809

Yazdani B, Xia Y, Ahmad I et al. (2015) Graphene and carbon nanotube (GNT)-reinforced alumina nanocomposites. J Eur Ceram Soc 35:179–186

Milsom B, Viola G, Gao Z et al. (2012) The effect of carbon nanotubes on the sintering behaviour of zirconia. J Eur Ceram Soc 32:4149–4156

Sarkar S, Das PK (2014) Effect of sintering temperature and nanotube concentration on microstructure and properties of carbon nanotube/alumina nanocomposites. Ceram Int 40:7449–7458

Trivedi MK, Nayak G, Tallapragada RM et al. (2015) Effect of biofield treatment on structural and morphological properties of silicon carbide. J Powder Metall Min 4:1–4

Gubicza J, Unga´r T, Wang Y et al. (2006) Microstructure of diamond–SiC nanocomposites determined by X-ray line profile analysis. Diam Relat Mater 15:1452–1456

Padmavathi N, Ghosal P, Prasad NE et al. (2012) Synthesis of carbon fibre-reinforced, silicon carbide composites by soft-solution approach. Sadhana 37:493–502

Acknowledgement

The authors express their sincere gratitude to the Director, CSIR-CG&CRI, India for his kind permission to publish this work. The authors are thankful to Dr. Sandip Bysakh, Electron Microscopy Section, CSIR-CG&CRI, India and Council of Scientific and Industrial Research (CSIR), India for carrying-out the TEM study and financial support (ESC-0104) respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Probal Kr. Das—Retired Chief Scientist, CSIR-Central Glass & Ceramic Research Institute.

Rights and permissions

About this article

Cite this article

Sarkar, K., Sarkar, S. & Das, P.K. Spark plasma sintered multiwalled carbon nanotube/silicon carbide composites: densification, microstructure, and tribo-mechanical characterization. J Mater Sci 51, 6697–6710 (2016). https://doi.org/10.1007/s10853-016-9956-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9956-x