Abstract

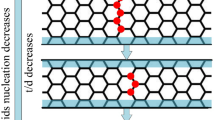

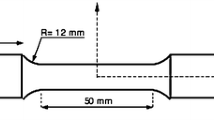

Due to forming processes of the upcoming manufacturing technology of sheet-bulk metal forming, where bulk forming operations are applied to sheet metal, ductile damage occurs due to high triaxial stress and strain states in the material. To consider this type of damage in models for an optimized process design, a description of the critical material state is required, taking the main damage mechanisms into account. In comparison to single-phase materials, where voids nucleate mainly at grain boundaries and triple junctions, in dual-phase materials also phase boundaries or the movement of different hard phases due to forming process contribute to ductile damage. In this study, the mechanisms of nucleation and growth of voids were analyzed in a dual-phase steel DP600 at different strain states and forming temperatures. By specimen preparation using ion-beam slope cutting and scanning electron microscopy, it was possible to observe at nano- and microscale voids, cracks, and elements of deformation reliefs. A correlation between the shape of voids and their location in the crystal lattice was found, whereby the mechanisms of their nucleation, growth, and coalescence could be described.

Similar content being viewed by others

References

Merklein M, Tekkaya AE, Brosius A, Opel S, Koch J (2011) Overview on sheet-bulk metal forming processes. Proceedings of the 10th international conference on technology of plasticity, ICTP, pp 1109–1114

Merklein M, Allwood JM, Behrens BA, Brosius A, Hagenah H, Kuzman K, Mori K, Tekkaya AE, Weckenmann A (2012) Bulk forming of sheet metal. CIRP Ann Manuf Technol 61(2):725–745. doi:10.1016/j.cirp.2012.05.007

Tasan CC, Diehl M, Yan D, Bechtold M, Roters F, Schemmann L, Zheng C, Peranio N, Ponge D, Koyama M, Tsuzaki K, Raabe D (2015) An overview of dual-phase steels: advances in microstructure-oriented processing and micromechanically guided design. Annu Rev Mater Res 45:391–431. doi:10.1146/annurev-matsci-070214-021103

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17(3):201–217

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: Part I. Yield criteria and flow rules for porous ductile materials. J Eng Mater Technol 99(1):2–15

Gologanu M, Leblond JB, Devaux J (1993) Approximate models for ductile metals containing non-spherical voids—Case of axisymmetric prolate ellipsoidal cavities. J Mech Phys Solids 41(11):1723–1754. doi:10.1016/0022-5096(93)90029-F

Gologanu M, Leblond JB, Perrin G, Devaux J (1997) Recent extensions of Gurson’s model for porous ductile metals. In: Suquet P (ed) Continuum micromechanics, CISM lectures series. Springer, New York, pp 61–130

Benzerga AA, Leblond JB (2010) Ductile fracture by void growth to coalescence. Adv Appl Mech 44:169–305. doi:10.1016/S0065-2156(10)44003-X

Benzerga AA (2002) Micromechanics of coalescence in ductile fracture. J Mech Phys Solids 50:1331–1362. doi:10.1016/S0022-5096(01)00125-9

Goods SH, Brown LM (1979) The nucleation of cavities by plastic deformation. Acta Metall 27(1):1–15. doi:10.1016/0001-6160(79)90051-8

Beevers CJ, Honeycombe RWK (1962) The initiation of ductile fracture in pure metals. Philos Mag 7(77):763–773

Besserer HB, Gerstein G, Maier HJ, Nürnberger F (2016) Specimen preparation by ion beam slope cutting for characterization of ductile damage by scanning electron microscopy. Microsc Res Tech 79(4):321–327. doi:10.1002/jemt.22633

Puttick KE (1959) Ductile fracture in metals. Philos Mag 4(44):964–969. doi:10.1080/14786435908238272

Kadkhodapour J, Butz A, Ziaei Rad S (2011) Mechanism of void formation during tensile testing in a commercial, dual-phase steel. Acta Mater 59(7):2575–2588. doi:10.1016/j.actamat.2010.12.039

Shabrov MN, Briant CL, Needleman A, Kim S, Sylven E, Sherman DH, Chuzhoy L (2004) Void nucleation by inclusion cracking. Metall Mater Trans A 35(6):1745–1755. doi:10.1007/s11661-004-0083-y

Besserer HB, Gerstein G, Dalinger A, Jablonik L, Rodman D, Nürnberger F (2016) Ion beam processing in the sample preparation for the analysis of ductile damage in deep drawing steels. Pract Metallogr PR M 53(4):221–236. doi:10.3139/147.110377

Hauffe W (1971) Electron microscopic studies on the development of the structure decomposition on metal surfaces after bombarded with 10 keV argon ions. Dissertation, Technische Universität Dresden

Isik K, Gerstein G, Clausmeyer T, Nürnberger F, Tekkaya AE, Maier HJ (2016) Evaluation of void nucleation and development during plastic deformation of dual-phase steel DP600. Steel Res Int. doi:10.1002/srin.201500483

Stroh AN (1954) The formation of cracks as a result of plastic flow. Proc R Soc Lond A 223:404–414. doi:10.1098/rspa.1954.0124

Mc Mahon CJ, Colen M (1965) Initiation of cleavage in polycrystalline iron. Acta Metall 13(6):591–604. doi:10.1016/0001-6160(65)90121-5

Vladimirov VI, Khannanov SK (1973) Actual problems of the theory of dislocation nucleation of cracks. Phys Metals Metall 30:490–510

Cottrell AH (1953) Dislocations and plastic flow in crystals. Clarendon Press, Oxford

Vladimirov VI (1984) Physical nature of metals fracture. Metallurgia, Moscow in Russian

Cheremskoy PG, Slezov VV, Betekhtin VI (1990) Voids in the solid. Energoatomizdat, Moscow in Russian. ISBN 5-283-03781-9

Gerstein G, Besserer HB, Nürnberger F, Maier HJ (2015) Comparison of the mechanisms of void formation by plastic deformation in single- and dual-phase bcc- steels. In: TMS Annual Meeting & Exhibition, proceedings characterization of minerals, metals and materials, Wiley, Hoboken, pp 75–78. doi: 10.1002/9781119093404.ch9

Lindley TC, Oates T, Richards CE (1970) A critical of carbide cracking mechanism in ferrite/carbide aggregates. Acta Metall 18(11):1127–1136. doi:10.1016/0001-6160(70)90103-3

Davies PW, Williams KR (1969) Strain-induced cavity development during creep metal. Metal Sci J 3(1):48–50. doi:10.1179/msc.1969.3.1.48

Mehrer H (2007) Diffusion in solids. Fundamentals, methods, materials, diffusion-controlled processes. Springer, Berlin

Maire E, Bouaziz O, Di Michiel M, Verdu C (2008) Initiation and growth of damage in a dual-phase steel observed by X-ray microtomography. Acta Mater 56(18):4954–4964. doi:10.1016/j.actamat.2008.06.015

Landron C, Bouaziz O, Maire E, Adrien J (2010) Characterization and modeling of void nucleation by interface decohesion in dual phase steels. Scr Mater 63(10):973–976. doi:10.1016/j.scriptamat.2010.07.021

Landron C, Bouaziz O, Maire E, Adrien J (2013) Experimental investigation of void coalescence in a dual phase steel using X-ray tomography. Acta Mater 61(18):6821–6829. doi:10.1016/j.actamat.2013.07.058

Elich JJ, Rosendaal HE, Kersten HH, Onderdelinden D, Kistemaker J, Elen JD (1971) Relation between surface structures and sputtering ratios of copper single crystals. Radiat Eff 8(1–2):1–11. doi:10.1080/00337577108231002

Thomas GJ, Miglionico CJ (1972) Scanning electron microscopy study of an ion etched uranium alloy. In: Thomas G (ed) Electron microscopy and structure of materials, 5. international materials symposium on the structure and properties of materials-techniques and applications of electron microscopy. University of California Press, Berkeley, pp 339–346

Acknowledgements

The authors thank the German Research Foundation (DFG) for financial support of the subproject C4 within the transregional collaborative research center SFB/TR 73.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gerstein, G., Besserer, HB., Nürnberger, F. et al. Formation and growth of voids in dual-phase steel at microscale and nanoscale levels. J Mater Sci 52, 4234–4243 (2017). https://doi.org/10.1007/s10853-016-0678-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0678-x