Abstract

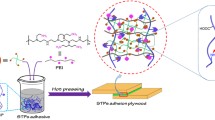

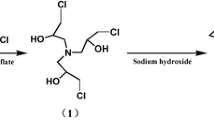

The goal of this investigation was to improve the water resistance of soybean meal-based (SM) bioadhesive and enhance the mechanical properties of the bonded plywood by combining triglycidylamine (TGA) cross-linking with an acrylic emulsion interpenetrating network (IPN). The solid content, functional groups, crystallinity, mass loss after hydrolyzing, fracture surface micrographs, and thermal stability of the resulting adhesives were characterized. Three-ply plywood was fabricated and its dry and wet shear strength was determined. The experimental results indicated that the introduction of 8 % TGA produced an improvement of 15.1 % in the water resistance of SM adhesive and 86.8 % in the wet shear strength of plywood as a result of the chemical cross-linking between epoxy groups and protein molecules. However, this reaction increased the brittleness of adhesive and caused an insufficient dry bond strength. Incorporating 8 % AE into the SM/TGA adhesive resulted in a water resistance that was improved by 24.6 %, a dry shear strength that was increased by 44.0 % to 1.80 MPa and a wet shear strength that was increased by 47.9 % to 1.05 MPa. The improvements were attributed to the formation of IPN which increased the solid content, improved the toughness of the adhesive, and promoted an uniform and compact cured structure. All results suggested that chemical cross-linking can effectively improve the water resistance of SM adhesive, but will aggravate the brittleness. Toughening improvement is an effective approach to enhance the performance of the SPAs and solve the low dry strength issue of resulting composites.

Similar content being viewed by others

References

Pizzi A (2013) Bioadhesives for wood and fibres: a critical review. Rev Adhes Adhes 1:88–113. doi:10.7569/RAA.2013.097303

Pizzi A (2006) Recent developments in eco-efficient bio-based adhesives for wood bonding: opportunities and issues. J Adhes Sci Technol 20:829–846. doi:10.1163/156856106777638635

Nordqvist P, Nordgren N, Khabbaz F, Malmström E (2013) Plant proteins as wood adhesives: bonding performance at the macro- and nanoscale. Ind Crop Prod 44:246–252. doi:10.1016/j.indcrop.2012.11.021

Acosta E (2007) Protein bioadhesives. Inform Cham 18:56

Cheng HN, Ford C, Dowd MK, He Z (2016) Soy and cottonseed protein blends as wood adhesives. Ind Crop Prod 85:324–330. doi:10.1016/j.indcrop.2015.12.024

Khosravi S, Nordqvist P, Khabbaz F, Öhman C, Bjurhager I, Johansson M (2015) Wetting and film formation of wheat gluten dispersions applied to wood substrates as particle board adhesives. Eur Polym J 67:476–482. doi:10.1016/j.eurpolymj.2014.11.034

Li N, Wang Y, Tilley M, Bean SR, Wu X, Sun XS, Wang D (2011) Adhesive performance of sorghum protein extracted from sorghum DDGS and flour. J Polym Environ 19:755–765. doi:10.1007/s10924-011-0305-5

Li J, Li X, Li J, Gao Q (2015) Investigating the use of peanut meal: a potential new resource for wood adhesives. RSC Adv 5:80136–80141

Ghosh Dastidar T, Netravali AN (2013) A soy flour based thermoset resin without the use of any external crosslinker. Green Chem 15:3243–3251. doi:10.1039/C3GC40887F

Sun XS (2011) Soy protein polymers and adhesion properties. J Biobased Mater Bioenergy 5:409–432. doi:10.1166/jbmb.2011.1183

Frihart CR, Birkeland MJ (2014) Soy properties and soy wood adhesives. In: Brentin RP (ed) Soy-Based Chemicals and Materials. Oxford University Press, Washington, DC, pp 167–192

Nordqvist P, Khabbaz F, Malmström E (2010) Comparing bond strength and water resistance of alkali-modified soy protein isolate and wheat gluten adhesives. Int J Adhes Adhes 30:72–79. doi:10.1016/j.ijadhadh.2009.09.002

Huang W, Sun X (2000) Adhesive properties of soy proteins modified by urea and guanidine hydrochloride. J Am Oil Chem Soc 77:101–104. doi:10.1007/s11746-000-0016-6

Huang W, Sun X (2000) Adhesive properties of soy proteins modified by sodium dodecyl sulfate and sodium dodecylbenzene sulfonate. J Am Oil Chem Soc 77:705–708. doi:10.1007/s11746-000-0113-6

Wang Y, Mo X, Sun XS, Wang D (2007) Soy protein adhesion enhanced by glutaraldehyde crosslink. J Appl Polym Sci 104:130–136. doi:10.1002/app.24675View/savecitation

Liu Y, Li K (2007) Development and characterization of adhesives from soy protein for bonding wood. Int J Adhes Adhes 27:59–67. doi:10.1016/j.ijadhadh.2005.12.004

Gao Q, Qin Z, Li C, Zhang S, Li J (2013) Preparation of wood adhesives based on soybean meal modified with PEGDA as a crosslinker and viscosity reducer. BioResources 8:5380–5391

Li H, Li C, Gao Q, Zhang S, Li J (2014) Properties of soybean-flour-based adhesives enhanced by attapulgite and glycerol polyglycidyl ether. Ind Crop Prod 59:35–40. doi:10.1016/j.indcrop.2014.04.041

Li J, Luo J, Li X, Yi Z, Gao Q, Li J (2015) Soybean meal-based wood adhesive enhanced by ethylene glycol diglycidyl ether and diethylenetriamine. Ind Crop Prod 74:613–618. doi:10.1016/j.indcrop.2015.05.066

Luo J, Li C, Li X, Luo J, Gao Q, Li J (2015) A new soybean meal-based bioadhesive enhanced with 5,5-dimethyl hydantoin polyepoxide for the improved water resistance of plywood. RSC Adv 5:62957–62965. doi:10.1039/C5RA05037E

Wang RM, Wang JF, Wang XW, He YF, Zhu YF, Jiang ML (2011) Preparation of acrylate-based copolymer emulsion and its humidity controlling mechanism in interior wall coatings. Prog Org Coat 71:369–375. doi:10.1016/j.porgcoat.2011.04.007

Connolly JM, Alferiev I, Eidelman N, Sacks M, Palmatory E, Kronsteiner A, DeFelice S, Xu J, Ohri R, Narula N, Vyavahare N, Levy RJ, Clark-Gruel JN (2005) Triglycidylamine crosslinking of porcine aortic valve cusps or bovine pericardium results in improved biocompatibility, biomechanics, and calcification resistance: chemical and biological mechanisms. Am J Pathol 166:1–13. doi:10.1016/S0002-9440(10)62227-4

GB/T 14074, (2006) Standardization Administration of the People’s Republic of China, Beijing

GB/T 17657, (2013) Standardization Administration of the People’s Republic of China, Beijing

Poletto M, Zattera AJ, Forte MMC, Santana RMC (2012) Thermal decomposition of wood: influence of wood components and cellulose crystallite size. Bioresource Technol 109:148–153. doi:10.1016/j.biortech.2011.11.122

Kamke FA, Lee JN (2007) Adhesive penetration in wood—a review. Wood Fiber Sci 39:205–220

Liu Y, Li K (2002) Chemical modification of soy protein for wood adhesives. Macromol Rapid Comm 23:739–742. doi:10.1002/1521-3927(20020901)23:13<739:AID-MARC739>3.0.CO;2-0

Gerrard JA (2002) Protein–protein crosslinking in food: methods, consequences, applications. Trends Food Sci Tech 13:391–399. doi:10.1016/S0924-2244(02)00257-1

Karnnet S, Potiyaraj P, Pimpan V (2005) Preparation and properties of biodegradable stearic acid-modified gelatin films. Polym Degrad Stabil 90:106–110. doi:10.1016/j.polymdegradstab.2005.02.016

Mekonnen TH (2014) Valorization of waste protein biomass for bio-based plastics, composites and adhesives development. PhD Dissertation, University of Alberta

Chen J, Chen X, Zhu Q, Chen F, Zhao X, Ao Q (2013) Determination of the domain structure of the 7S and 11S globulins from soy proteins by XRD and FTIR. J Sci Food Agr 93:1687–1691. doi:10.1002/jsfa.5950

Colby R, Rubinstein M (2003) Polymer physics. Oxford University Press, New Yoyk

Kumar R, Choudhary V, Mishra S, Varma IK (2004) Enzymatically-modified soy protein part 2: adhesion behaviour. J Adhes Sci Technol 18:261–273. doi:10.1163/156856104772759458

Qin Z, Gao Q, Zhang S, Li J (2013) Glycidyl methacrylate grafted onto enzyme-treated soybean meal adhesive with improved wet shear strength. BioResources 8:5369–5379

Qi G, Sun X (2011) Soy protein adhesive blends with synthetic latex on wood veneer. J Am Oil Chem Soc 88:271–281. doi:10.1007/s11746-010-1666-y

Zhang Y, Zhu W, Lu Y, Gao Z, Gu J (2014) Nano-scale blocking mechanism of MMT and its effects on the properties of polyisocyanate-modified soybean protein adhesive. Ind Crop Prod 57:35–42. doi:10.1016/j.indcrop.2014.03.027

Gao Z, Zhang Y, Fang B, Zhang L, Shi J (2015) The effects of thermal-acid treatment and crosslinking on the water resistance of soybean protein. Ind Crop Prod 74:122–131. doi:10.1016/j.indcrop.2015.04.026

Acknowledgements

The authors are grateful for financial support from Beijing Natural Science Foundation (2151003) and the Special Fund for Forestry Research in the Public Interest (201404501).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Luo, J., Luo, J., Li, X. et al. Toughening improvement to a soybean meal-based bioadhesive using an interpenetrating acrylic emulsion network. J Mater Sci 51, 9330–9341 (2016). https://doi.org/10.1007/s10853-016-0180-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0180-5