Abstract

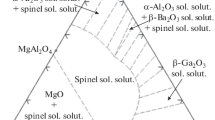

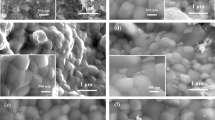

Aqueous sol–gel processing was used to synthesize neodymium-doped magnesium hexaaluminate (La1−x Nd x MgAl11O19; x = 0, 0.3, 0.4, 0.5) ceramic powder and subsequently calcined at 1450 and 1600 °C for 2 h. Randomly grown platelets of lanthanum–magnesium hexaaluminate formed a porous interlocking structure. Presence of various percentages of neodymium oxide significantly modifies the porous interlocking microstructure into self-reinforced, card-house-like microstructure. Platelets of rare earth-rich magnesium hexaaluminate were grown preferentially more than the stoichiometric rare earth magnesium hexaaluminate at elevated temperature greater than 1450 °C. Rare earth-rich magnesium hexaaluminate platelets form the skeleton of a card-house structure and the tiny platelets of stoichiometric rare earth magnesium hexaaluminate fill the house. The specific heat capacities, micro-hardness, and fracture toughness were studied in details.

Similar content being viewed by others

References

Miller RA (1987) Current status of thermal barrier coatings—an overview. Surf Coat Technol 30(1):1–11

Padture NP, Gell M, Jordan EH (2002) Thermal barrier coatings for gas-turbine engine applications. Science 296(5566):280–284

Levi CG (2004) Emerging materials and processes for thermal barrier systems. Curr Opin Solid State Mater Sci 8(1):77–91

Vassen R, Jarligo MO, Steinke T, Mack DE, Stover D (2010) Overview on advanced thermal barrier coatings. Surf Coat Technol 205(4):938–942

Clarke DR, Phillpot SR (2005) Thermal barrier coating materials. Mater Today 8(6):22–29

Cao XQ, Zhang YF, Zhang JF, Zhong XH, Wang Y, Ma HM, Xu ZH, He LM, Lu F (2008) Failure of the plasma-sprayed coating of lanthanum hexaluminate. J Eur Ceram Soc 28(10):1979–1986

Cao XQ, Vassen R, Stoever D (2004) Ceramic materials for thermal barrier coatings. J Eur Ceram Soc 24(1):1–10

Azzopardi A, Mevrel R, Saint-Ramond B, Olson E, Stiller K (2004) Influence of aging on structure and thermal conductivity of Y-PSZ and Y-FSZ EB-PVD coatings. Surf Coat Technol 177–178:131–139

Clarke DR (2003) Materials selection guidelines for low thermal conductivity thermal barrier coatings. Surf Coat Technol 163–164:67–74

Vassen R, Cao X, Tietz F, Basu D, Stover D (2000) Zirconates as New Materials for Thermal Barrier Coatings. J Am Ceram Soc 83(8):2023–2028. doi:10.1111/j.1151-2916.2000.tb01506.x

Gadow R, Lischka M (2002) Lanthanum hexaaluminate—novel thermal barrier coatings for gas turbine applications - materials and process development. Surf Coat Technol 151–152:392–399

Friedrich C, Gadow R, Schirmer T (2001) Lanthanum hexaaluminate—a new material for atmospheric plasma spraying of advanced thermal barrier coatings. J Therm Spray Technol 10(4):592–598. doi:10.1361/105996301770349105

Choi SR, Bansal NP, Zhu D (2008) Mechanical and thermal properties of advanced oxide materials for higher-temperature coatings applications. In: Advances in ceramic coatings and ceramic-metal systems: ceramic engineering and science proceedings. Wiley, pp 11–19. doi:10.1002/9780470291238.ch2

Cao XQ, Vassen R, Jungen W, Schwartz S, Tietz F, Stover D (2001) Thermal stability of lanthanum zirconate plasma-sprayed coating. J Am Ceram Soc 84(9):2086–2090. doi:10.1111/j.1151-2916.2001.tb00962.x

Bansal NP, Zhu D (2008) Thermal properties of oxides with magnetoplumbite structure for advanced thermal barrier coatings. Surf Coat Technol 202(12):2698–2703

Chen X, Zhang Y, Zhong X, Xu Z, Zhang J, Cheng Y, Zhao Y, Liu Y, Fan X, Wang Y, Ma H, Cao X (2010) Thermal cycling behaviors of the plasma sprayed thermal barrier coatings of hexaluminates with magnetoplumbite structure. J Eur Ceram Soc 30(7):1649–1657

Negahdari Z, Willert-Porada M, Scherm F (2010) Thermal properties of homogenous lanthanum hexaaluminate/alumina composite ceramics. J Eur Ceram Soc 30(15):3103–3109

Zhu D, Fox DS, Bansal NP, Miller RA (2004) Advanced oxide material systems for 1650°C thermal/environmental barrier coating applications. NASA/TM—2004-213219. National Aeronautics and Space Administration, Washington

Dudkin BN, Bugaeva AY, Zainullin GG, Filippov VN (2004) The effect of yttrium oxide on the microstructure and properties of ceramics based on lanthanum hexaaluminate synthesized by the sol–gel method. Refract Ind Ceram 45(1):31–35. doi:10.1023/b:refr.0000023348.19718.73

Wang Y-H, Ouyang J-H, Liu Z-G (2009) Preparation and thermo-physical properties of La1−x Nd x MgAl11O19 (x = 0, 0.1, 0.2) ceramics. J Alloys Compd 485(1–2):734–738

Wang Y-H, Liu Z-G, Ouyang J-H, Liu H-Z, Zhu R-X (2011) Preparation and thermophysical properties of LaMgAl11O19-Yb3Al5O12 ceramic composites. Ceram Int 37(7):2489–2493

Wang Y-H, Ouyang J-H, Liu Z-G (2010) Influence of dysprosium oxide doping on thermophysical properties of LaMgAl11O19 ceramics. Mater Des 31(7):3353–3357

Barrera-Solano C, Esquivias L, Messing GL (1999) Effect of preparation conditions on phase formation, densification, and microstructure evolution in La-β-Al2O3/Al2O3 composites. J Am Ceram Soc 82(5):1318–1324. doi:10.1111/j.1151-2916.1999.tb01914.x

Wu YQ, Zhang YF, Huang XX, Guo JK (2001) In-situ growth of needlelike LaAl11O18 for reinforcement of alumina composites. Ceram Int 27(8):903–906

Jang BK, Kishi T (1998) Fabrication and microstructure of Al2O3 matrix composites by in situ reaction in the Al2O3–La2O3 system. J Ceram Soc Jpn 106(8):739–743

Negahdari Z, Willert-Porada M (2010) Tailoring the microstructure of reaction-sintered alumina/lanthanum hexaaluminate particulate composites. J Eur Ceram Soc 30(6):1381–1389

Wu Y-Q, Zhang Y-F, Wang S-W, Guo J-K (2001) In-situ synthesis of rodlike LaAl11O18 in Al2O3 powder by a coprecipitation method. J Eur Ceram Soc 21(7):919–923

Zhu R-X, Liu Z-G, Ouyang J-H, Zhou Y (2013) Preparation and characterization of LnMgAl11O19 (Ln = La, Nd, Gd) ceramic powders. Ceram Int 39(8):8841–8846. doi:10.1016/j.ceramint.2013.04.073

Teng F, Man Y, Liang S, Buergen G, Zhu Y, Han W, Xu P, Xiong G, Tian Z (2007) Crystal structure stability and catalytic activity of magnetoplumbite (MP) catalyst doped with Mn and Mg. J Non-Cryst Solids 353(52–54):4806–4812

Rao RR, Mariappan L (2005) Combustion synthesis and characterisation of lanthanum hexa-aluminate. Adv Appl Ceram 104:268–271

Cinibulk MK (1995) Synthesis and characterization of sol-gel derived lanthanum hexaluminate powders and films. J Mater Res 10(1):71–76

Ropp RC, Carroll B (1980) Solid-state kinetics of LaAl11O18. J Am Ceram Soc 63(7–8):416–419. doi:10.1111/j.1151-2916.1980.tb10203.x

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J Am Ceram Soc 64(9):533–538. doi:10.1111/j.1151-2916.1981.tb10320.x

Gobichon A-E, Auffrdic J-P, Lour D (1996) Thermal decomposition of neutral and basic lanthanum nitrates studied with temperature-dependent powder diffraction and thermogravimetric analysis. Solid State Ionics 93(1–2):51–64

Jia PY, Yu M, Lin J (2005) Sol-gel deposition and luminescent properties of LaMgAl11O19:Ce3+/Tb3+ phosphor films. J Solid State Chem 178(9):2734–2740

Kaya C, Butler EG (2002) Plastic forming and microstructural development of α-alumina ceramics from highly compacted green bodies using extrusion. J Eur Ceram Soc 22(12):1917–1926

Zhang J, Zhong X, Cheng Y, Wang Y, Xu Z, Chen X, Ma H, Zhao Y, Cao X (2009) Thermal-shock resistance of LnMgAl11O19 (Ln = La, Nd, Sm, Gd) with magnetoplumbite structure. J Alloys Compd 482(1–2):376–381

Rohrer GS (2004) Structure and bonding in crystalline materials. Cambridge University Press, Cambridge

Priya GK, Padmaja P, Warrier K, Damodaran A, Aruldhas G (1997) Dehydroxylation and high temperature phase formation in sol-gel boehmite characterized by Fourier transform infrared spectroscopy. J Mater Sci Lett 16(19):1584–1587. doi:10.1023/a:1018568418302

Singh V, Chakradhar RPS, Rao JL, Kwak HY (2011) Enhanced blue emission and EPR study of LaMgAl11O19:Eu phosphors. J Lumin 131(2):247–252

Zhan G, Yu J-x, Xu Z-g, Zhou F, Chi R-a (2012) Kinetics of thermal decomposition of lanthanum oxalate hydrate. Trans Nonferrous Met Soc 22:925–934

Getman E, Loboda S, Tkachenko T, Ignatov A (2005) Substitution of calcium with neodymium and dysprosium in hydroxyapatite structure. Funct. Mater 12(1):6–10

Rice RW, Wu CC, Boichelt F (1994) Hardness–Grain-size relations in ceramics. J Am Ceram Soc 77(10):2539–2553. doi:10.1111/j.1151-2916.1994.tb04641.x

Acknowledgements

The authors would like to thank M/s. Carborundum Universal Limited, India for sponsoring this research work. Technical staffs of Central Research Facility (CRF) of Indian Institute of Technology, Kharagpur and Sophisticated Analysis and Instrument Facility (SAIF), Cochin are sincerely acknowledged for their extended support during SEM, FTIR, and XRD analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jana, P., Jayan, P.S., Mandal, S. et al. Microstructural design of neodymium-doped lanthanum–magnesium hexaaluminate synthesized by aqueous sol–gel process. J Mater Sci 50, 344–353 (2015). https://doi.org/10.1007/s10853-014-8593-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8593-5