Abstract

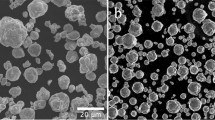

Room temperature tensile testing was performed on a coarse-grained polycrystalline Ni (32 μm), a nanocrystalline Ni (23 nm) and two nanocrystalline Ni–Fe (16 nm) electrodeposits at two strain rates of 10−1 and 10−2/s. Strain localizations and local temperature increases were simultaneously recorded during tensile testing. For all materials, higher loads or higher strain rate generally resulted in higher peak temperature with the highest temperatures recorded in the fracture regions. The maximum temperature for the nanocrystalline materials was just over 80 °C, which is significantly below the reported temperatures for the onset of thermally activated grain growth. Therefore, the previously reported grain growth observed on similar materials after tensile deformation is likely not thermally activated but a stress-induced phenomenon. Despite the wide grain range from 16 nm to 32 μm, all samples exhibited similar strain localization behavior. Local strain variations initiated in the early stage of macroscopic uniform deformation, subsequent necking and fracture took place in the region of initial strain localization. While the coarse-grained polycrystalline Ni exhibited little strain rate sensitivity, gradually increased strain rate sensitivity was observed for the 23 nm Ni and the two 16 nm Ni–Fe samples, suggesting that both dislocation-mediated and grain-boundary-controlled mechanisms were operative in the deformation of the nanocrystalline Ni and Ni–Fe samples.

Similar content being viewed by others

References

Weertman JR (2007) Mechanical behavior of nanocrystalline metals. In: Koch CC (ed) Nanostructured materials, 2nd edn. William Andrew Publications, Norwich, NY, pp 537–564

Koch CC (2007) Structural nanocrystalline materials: an overview. J Mater Sci 42:1403–1414

Whang SH (ed) (2011) Nanostructured metals and alloys. Woodhead Publ Ltd, Oxford

Chokshi AH, Rosen A, Karch J, Gleiter H (1989) On the validity of the Hall-Petch relationship in nanocrystalline materials. Scripta Metall Mater 23:1679–1684

Siegel RW, Fougere GE (1995) Mechanical properties of nanophase metals. Nanostr Mater 6:205–216

Erb U, Aust KT, Palumbo G (2007) Electrodeposited nanocrystalline metals, alloys, and composites. In: Koch CC (ed) Nanostructured materials, 2nd edn. William Andrew Publications, Norwich, NY, pp 235–292

Kumar KS, Van Swygenhoven H, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Mater 51:5743–5774

Ebrahimi F, Zhai Q, Kong D (1998) Deformation and fracture of electrodeposited copper. Scripta Mater 39:315–321

Ebrahimi F, Bourne GR, Kelly MS, Matthews TE (1999) Mechanical properties of nanocrystalline nickel produced by electrodeposition. Nanostruct Mater 11:343–350

Dalla Torre F, Van Swygenhoven H, Victoria M (2002) Nanocrystalline electrodeposited Ni: microstructure and tensile properties. Acta Mater 50:3957–3970

Ma E (2003) Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scripta Mater 49:663–668

Panin AV, Panina AA, Ivanov YF (2008) Deformation macrolocalisation and fracture in ultrafine-grained armco iron. Mater Sci Eng A 486:267–272

Cheng S, Ma E, Wang YM, Kecskes LJ, Youssef KM, Koch CC, Trociewitz UP, Han K (2005) Tensile properties of in situ consolidated nanocrystalline Cu. Acta Mater 53:1521–1533

Wei Q, Jia D, Ramesh KT (2002) Evolution and microstructure of shear bands in nanostructured Fe. Appl Phys Lett 81:1240–1242

Fu H, Benson DJ, Meyers MA (2004) Computational description of nanocrystalline deformation based on crystal plasticity. Acta Mater 52:4413–4425

Sansoz F, Dupont V (2007) Atomic mechanism of shear localization during indentation of a nanostructured metal. Mater Sci Eng C 5–8:1509–1513

Joshi SP, Ramesh KT (2008) Grain size dependent shear instabilities in body-centered and face-centered cubic materials. Mater Sci Eng A 493:65–70

Fan GJ, Fu LF, Choo H, Liaw PK, Browning ND (2006) Uniaxial tensile plastic deformation and grain growth of bulk nanocrystalline alloys. Acta Mater 54:4781–4792

Fan GJ, Fu LF, Qiao DC, Choo H, Liaw PK, Browning ND (2006) Grain growth in a bulk nanocrystalline Co alloy during tensile plastic deformation. Scripta Mater 54:2137–2141

Erb U, El-Sherik AM (1994) US Patent # 5,353,266, October 1994

Erb U, El-Sherik AM, Cheung CKS, Aus MJ (1995) US Patent # 5,433,797, July 1995

Erb U, Palumbo G, McCrea JL (2011) The processing of bulk nanocrystalline metals and alloys by electrodeposition. In: Whang SH (ed) Nanostructured metals and alloys: processing, microstructure, mechanical properties and applications. Cambridge Woodhead Publishing Ltd., Oxford, pp 118–151

Hibbard G, Erb U, Aust KT, Klement U, Palumbo G (2002) Thermal stability of nanostructured electrodeposits. Mater Sci Forum 386–388:387–396

Klement U, Erb U, Aust KT (1995) Investigations of the grain growth behavior of nanocrystalline nickel. Nanostruct Mater 6:581–584

Brooks I, Lin P, Palumbo G, Hibbard GD, Erb U (2008) Hardness-tensile strength relationships for nanocrystalline materials. Mater Sci Eng A 491:412

Brooks I, Palumbo G, Hibbard GD, Wang Z, Erb U (2011) On the intrinsic ductility of electrodeposited nanocrystalline metals. J Mater Sci 46:7713

Cullity BD (1978) Elements of X-ray diffraction, 2nd edn. Addison-Wesley, Reading, MA, p 102

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556

Gu CD, Lian JS, Jiang Q, Zheng WT (2007) Experimental and modeling investigations on strain rate sensitivity of an electrodeposited 20 nm grain sized Ni. J Phys D Appl Phys 40:7440–7446

Wang YM, Ma E (2004) On the origin of ultrahigh cryogenic strength of nanocrystalline metals. Appl Phys Lett 85:2750–2752

Dalla Torre F, Spatig P, Schaublin R, Victoria M (2005) Deformation behaviour and microstructure of nanocrystalline electrodeposited… pressure torsioned nickel. Acta Mater 53:2337–2349

Wei Q, Cheng S, Ramesh KT, Ma E (2004) Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater Sci Eng A 381:71–79

Asaro RJ, Suresh S (2005) Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater 53:3369–3392

Gu CD, Lian JS, Jiang Q, Jiang ZH (2007) Ductile-brittle-ductile transition in an electrodeposited 13 nanometer grain sized Ni-8.6wt.%Co alloy. Mater Sci Eng A459:75–81

Gu P, Dao M, Asaro RJ, Suresh S (2011) A unified mechanistic model for size-dependent deformation in nanocrystalline and nanotwinned metals. Acta Mater 59:6861–6868

Dao M, Lu L, Asaro RJ, De Hosson JTM, Ma E (2007) Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater 55:4041–4065

Van Swygenhoven H, Spaczer M, Caro A (1999) Microscopic description of plasticity in computer generated metallic nanophase samples: a comparison between Cu and Ni. Acta Mater 47:3117–3126

Conrad H (2003) Grain size dependence of the plastic deformation kinetics in Cu. Mater Sci Eng A341:216–228

Dieter GE (1988) Mechanical metallurgy, SI Metric. McGraw-Hill Publications, New York, NY

Chu TC, Ranson WF, Sutton MA, Peters WH (1985) Application of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232–244

Zhu R, Zhou J, Jiang H, Lui Y, Ling X (2010) Multi-scale modeling of shear banding in fully dense nanocrystalline Ni sheet. Mater Sci Eng A 527:1751–1760

Zhao YH, Guo YZ, Wei Q, Topping TD, Dangelewicz AM, Zhu YT, Langdon TG, Lavernia EJ (2009) Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves. Mater Sci Eng A 525:68–77

Taylor GI, Quinney H (1934) The latent energy remaining in metal after cold working. Proc R Soc Lond Ser A 143:307–326

Bever MB, Holt DL, Titchener AL (1973) The stored energy of cold work. Prog Mater Sci 17:5–177

Wang S, Zhou Y, Erb U et al Thermoelectrical transport in nanocrystalline Ni (in preparation)

Turi T, Erb U (1995) Thermal expansion and heat capacity of porosity-free nanocrystalline materials. Mater Sci Eng A203:34–38

Gale WF, Totemeier TL (eds) (2004) Smithhells metals reference book, 8th edn. Elsevier Butterworth-Heinemann, Burlington, MA, p 14–25

Erb U (2012) Size effects and structure-sensitivity of properties in electrodeposited nanomaterials. Mater Sci For 706–709:1601–1606

Callister WD (2001) Fundamentals of materials science and engineering, 5th edn. Wiley, New York, p S-251

Hibbard GD, Radmilovic V, Aust KT, Erb U (2008) Grain boundary migration during abnormal grain growth in nanocrystalline Ni. Mater Sci Eng A494:232–238

Hibbard GD, Aust KT, Erb U (2008) On interfacial velocities during abnormal grain growth at ultra-high driving forces. J Mater Sci A43:6441–6452

Ghosh AK, Hamilton CH (1979) Mechanical behavior and hardening characteristics of a superplastic Ti-6Al-4 V alloy. Metall Trans 10A:699–706

Senkov ON, Myshlyaev MM (1986) Grain growth in a superplastic Zn-22 % Al alloy. Acta Metall 34:97–106

Shan Z, Stach EA, Wiezorek JMK, Knapp JA, Follstaedt DM, Mao SX (2004) Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305:654–657

Haslam AJ, Moldovan D, Yamakov V, Wolf D, Phillpot SR, Gleiter H (2003) Stress-enhanced grain growth in a nanocrystalline material by molecular-dynamics simulation. Acta Mater 51:2097–2112

Schiøtz Jakob (2004) Strain-induced coarsening in nanocrystalline metals under cyclic deformation. Mater Sci Eng A 375–377:975–979

Jin M, Minor AM, Stach EA, Morris JW (2004) Direct observation of deformation-induced grain growth during the nanoindentation of ultrafinegrained Al at room temperature. Acta Mater 52:5381–5387

Zhang K, Weertman JR, Eastman JA (2005) Rapid stress-driven grain coarsening in nanocrystalline Cu at ambient and cryogenic temperatures. Appl Phys Lett 87:061921

Gianola DS, Van Petegem S, Legros M, Brandstetter S, Van Swygenhoven H, Hemker KJ (2006) Stress assisted discontinuous grain growth and its effect on the deformation behavior of nanocrystalline aluminum thin films. Acta Mater 54:2253–2263

Cahn JW, Mishin Y, Suzuki A (2006) Coupling grain boundary motion to shear deformation. Acta Mater 54:4953–4975

Brandstetter S, Zhang K, Escuadro A, Weertman JR, Van Swygenhoven H (2008) Grain coarsening during compression of bulk nanocrystalline nickel and copper. Scripta Mater 58:61–64

Farkas D, Mohanty S, Monk J (2008) Strain-driven grain boundary motion in nanocrystalline materials. Mater Sci Eng A493:33–40

Wang YB, Li BQ, Sui ML, Mao SX (2008) Deformation-induced grain rotation and growth in nanocrystalline Ni. Appl Phys Lett 92:011903

Rupert TJ, Gianola DS, Gan Y, Hemker KJ (2009) Experimental observations of stress-driven grain boundary migration. Science 18:1686–1690

Xu W, Dai P, Wu X (2010) Effect of stress-induced grain growth during room temperature tensile deformation on ductility in nanocrystalline metals. Bull Mater Sci 33:561–568

Tucker GJ, Foiles SM (2013) Molecular dynamics simulations of rate-dependent grain growth during the surface indentation of nanocrystalline nickel. Mater Sci Eng A571:207–214

Acknowledgements

The authors would like to thank Dr. David Backman, Mr. Richard Bos and Mr. Thomas Sears from the National Research Council, Institute of Aerospace Research for their help and many valuable suggestions during the DIC and infrared experiments. YZ would like to thank Mr. Cho for the fruitful discussion on thermal and electric transport in nanocrystalline metals. Highly appreciated is the financial support by the Natural Sciences and Engineering Research Council of Canada (NSERC) and the Ontario Research Fund (ORF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chan, T., Zhou, Y., Brooks, I. et al. Localized strain and heat generation during plastic deformation in nanocrystalline Ni and Ni–Fe. J Mater Sci 49, 3847–3859 (2014). https://doi.org/10.1007/s10853-014-8099-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8099-1