Abstract

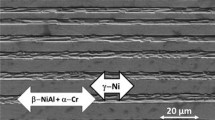

To understand the degradation of two thermal barrier coating (TBC) systems, we determined the adhesion energy between the bondcoat and the topcoat and its evolution during cyclic oxidation at 1,100 °C, by means of a modified 4-point bending test. An yttria stabilized zirconia (YSZ) ceramic topcoat was deposited by electron beam physical vapour deposition (EBPVD) on a Ni-based superalloy with either an intermediate β-(Ni,Pt)Al bondcoat or a newly developed Zr-doped β-NiAl bondcoat. Although a similar evolution of the adhesion energy during cyclic oxidation has been recorded for both systems, observations of the fracture surfaces combined with a microstructure study revealed different degradation mechanisms. An energetic model of spallation is applied to predict their lifetime. According to this approach, the TBC failure is induced by the accumulation of strain energy in the ceramic layers and resisted by the interfacial fracture toughness. The predicted lifetime is consistent with experiments for both systems.

Similar content being viewed by others

Notes

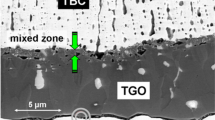

In the case of remaining alumina blocks onto the β-(Ni,Pt)Al bondcoat, this energy was lowered according to the fraction part area of standing adhesive TGO, as measured on fracture surfaces.

References

Mumm DR, Evans AG (2000) Acta Mater 48:1815

Vasinonta A, Beuth JL (2001) Eng Fract Mech 68:843

Watanabe M, Kuroda S, Yokoyama K et al (2008) Surf Coat Technol 202:1746

Guerre C (2002) PhD Thesis, Ecole Nationale Supérieure des Mines de Paris

Kim S, Liu Y, Kagawa Y (2007) Acta Mater 55:3771

Arai M, Okajima Y, Kishimoto K (2007) Eng Fract Mech 74:2055

Charalambides PG, Jund J, Evans AG, McMeeking RM (1989) J Appl Mech 56:77

Gan Z, Mhaisalkar SG, Chen Z et al (2005) Surf Coat Technol 198:85

Li H, Khor KA, Cheang P (2007) Eng Fract Mech 74:1894

Hofinger I, Oechsner M, Bahr HA et al (1998) Int J Fracture 92:213

Quian L, Zhu S, Kagawa Y (2003) In: 27th international conference on advanced ceramics and composites: a (Cocoa Beach, FL, USA), vol 24, issue 3, p 503

Yamasaki Y, Schmidt A, Scholz A (2006) Surf Coat Technol 201:744

Bahr HA, Balke H, Fett T et al (2003) Mater Sci Eng A 362:2

Théry PY (2007) Thèse de Doctorat, Universite Joseph Fourier Grenoble, France, Matériaux et Génie des Procédés

Théry PY, Poulain M, Dupeux M, Braccini M (2007) Surf Coat Technol 202:648

Noebe RD, Bowman RR, Nathal MV (1993) Int Mater Rev 38:193

Li YZ, Wang C, Chan HM et al (1999) J Am Ceram Soc 82:1497

Evans AG, Mumm DR, Hutchinson JW et al (2001) Prog Mater Sci 46:505

Hutchinson JW, Evans AG (2002) Surf Coat Technol 149:179

Xu T, Faulhaber S, Mercer C et al (2004) Acta Mater 52:1439

Spitsberg IT, Mumm DR, Evans AG (2005) Mater Sci Eng A 394:176

Zhao X, Wang X, Xiao P (2006) Surf Coat Technol 200:5946

Shih CF (1991) Mater Sci Eng A 143:77

Faulhaber S, Mercer C, Moon MW et al (2006) J Mech Phys Solids 54:1004

Hutchinson JW, Suo Z (1992) Adv Appl Mech 29:63

Wang JS, Evans AG (1998) Acta Mater 46:4993

Wang JS, Evans AG (1999) Acta Mater 47:699

Lipkin DM, Clarke DR, Hollatz M et al (1997) Corr Sci 39:231

Acknowledgements

The authors are indebted to Dr. R. Mevrel (ONERA) for helpful discussions during the course of this study, and to Dr. N. Terrien (ONERA) for his assistance in the PLPS measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Théry, PY., Poulain, M., Dupeux, M. et al. Spallation of two thermal barrier coating systems: experimental study of adhesion and energetic approach to lifetime during cyclic oxidation. J Mater Sci 44, 1726–1733 (2009). https://doi.org/10.1007/s10853-008-3108-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3108-x