Abstract

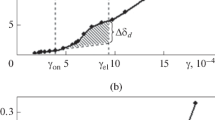

The effects of temperature on the damping behavior of bulk graphite were investigated and some novel phenomena were observed. The internal friction (IF) background of the bulk graphite has small temperature dependent and the IF value is much smaller than that of reported data. Moreover, two IF peaks were found in the IF-temperature spectrums. The first is proved to originate from the sweeping motion of in-plane dislocations and is a relaxation-type IF peak. The average activation energy of the peak is around 1.10 ± 0.06 eV and the pre-exponential factor τ 0 is 10−14 s. The second is a transformation peak, resulting from the transformation of asphalt that was used as binder in preparation of bulk graphite.

Similar content being viewed by others

References

Everett RK, Arsenault RJ (1991) Metal matrix composites processing and interfaces. Academic Press, Boston, MA, p 3

Taya M, Arsenault RJ (1989) Metal matrix composites thermomechanical behavior. Pergamon Press, Oxford, p 126

Wei JN, Cheng HF, Gong CL, Han FS, Shui JP (2002) Metab Mater Trans A 33:3565. doi:https://doi.org/10.1007/s11661-002-0344-6

Rawal SP, Misra MS (1986) In: Rath BB, Misra MS (eds) Role of interfaces on material damping. ASM, Materials Park, Ohio, p 18

Updike CA, Bhagat RB, Pechersky MJ, Amateau MF (1990) J Met 42:42

Rohatgi PK, Asthan R, Kumar A, Nath D, Shroeffer S (1988) In: Fishman SG, Dhingra AK (eds) Cast reinforced metal composite. ASM, Materials Park, Ohio, p 264

Taya M (1991) Mater Trans JIM 32:1

Kelly BT (1981) Physics of graphite. Appl Sci Publ, London, p 8

Rohatgi PK, Murali N, Shetty HR, Chandrashekhar R (1976) Mater Sci Eng 26:115. doi:https://doi.org/10.1016/0025-5416(76)90233-0

Zhang J, Perez RJ, Gungor MN, Lavernia EJ (1992) In: Upadhya K (ed) Developments in ceramic and metal-matrix composites. TMS, Warrendale, PA, p 107

Zhang J, Perez RJ, Gungor MN, Lavernia EJ (1993) In: Bhagat RB (ed) Damping of multiphase inorganic materials. AMS International, Materials Park OH, p 127

Zhang J, Perez RJ, Gungor MN, Lavernia EJ (1993) Scr Metall Mater 28:91. doi:https://doi.org/10.1016/0956-716X(93)90543-2

Perez RJ, Zhang J, Lavernia EJ (1991) Proceedings of 17th Int. Symp For Testing and Failure Analysis, ISTFA/91. ASM International, Materials Park, OH, p 445

Bevington PR (1969) Data reduction and error analysis for the physical science. McGraw-Hill, New York, p 26

Delmonte J (1981) Technology of carbon and graphite fiber composites. Van Nostrand Reinhold Company, p 6

Granato A, Lücke K (1981) J Appl Phys 52:7136. doi:https://doi.org/10.1063/1.328687

Nowick AS, Berry BS (1972) Anelastic relaxation in crystalline solids. Academic Press, New York, p 28

Delorme JE, Gobin PF (1973) Metaux corrosion-industrie 573:185

Wei JN, Wang DY, Xie WJ, Luo JL, Han FS (2007) Phys Lett A 366:134. doi:https://doi.org/10.1016/j.physleta.2007.01.061

Wei JN, Li YL, Song SH, Ji GC, Ma ML, Zhang DQ (2004) Phys Status Solid 201:923. doi:https://doi.org/10.1002/pssa.200306778

Acknowledgements

The authors are grateful to the Jiangxi Province Natural Science Foundation of China (ratification No: 0550050) and the Jiangxi Provincial Department of Education Foundation of China (ratification No: 13-3-B-04) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, J.N., Huang, T.C., Zhao, L. et al. Internal friction characterization of graphite. J Mater Sci 43, 5470–5473 (2008). https://doi.org/10.1007/s10853-008-2824-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2824-6