Abstract

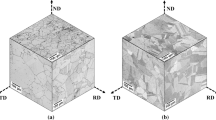

The microstructural features of INCOLOY alloy 617 in the solution annealed condition and after long-term creep tests at 700 and 800 °C were characterized and correlated with hardness and creep strength. Major precipitates included (Cr,Mo,Fe)23C6 carbides and the δ-Ni3Mo phase. M6C and MC carbides were also detected within the austenitic grains. However, minor precipitates particularly γ′-Ni3(Al,Ti) was found to play an important role. At different exposure temperatures, the microstructural features of the Ni–22Cr–12Co–9Mo alloy changed compared with the as-received condition. The presence of discontinuously precipitated (Cr,Mo,Fe)23C6 carbides and their coarsening until the formation of an intergranular film morphology could be responsible both for a reduction in rupture strength and for enhanced intergranular embrittlement. The fraction and morphology of the γ′-phase, precipitated during exposure to high temperature, also changed after 700 or 800 °C exposure. At the latter test temperature, a lower volume fraction of coarsened and more cubic γ′ precipitates were observed. These microstructural modifications, together with the presence of the δ-phase, detected only in specimens exposed to 700 °C, were clearly responsible for the substantially good creep response observed at 700 °C, compared with that found at 800 °C.

Similar content being viewed by others

References

Blum R, Vanstone RW (2005) ParsonS 2003, 1st Int. Conf. super-high strength steels, 2–4 Nov. 2005, Rome

Viswanathan R, Hanry JF, Tanzosh J, Stanko G, Schlingledecker J (2005) In: Shibli IA, Holdsworth SR, Merckling G (eds) Proc Conf. creep & fracture at high temperature components, 12–14 Sept. 2005, DEStech Publications, Lancaster, PA, p 59

Röster J, Götting M, Del Genovese D, Böttiger B, Kopp P, Wolske M, Shubert F, Pemkolla HJ, Seliga T, Thoma A, Sholz A, Berger C (2005) Adv Eng Mat 5:469

Donachie MJ, Donachie SJ (2002) Superalloys—a technical guide, 2nd edn. ASM International, Materials Park, OH, p 1

Martin U, Oetttel H, Mühle U, Jerenz M (2001) Adv Eng Mat 3:871

Cozar R, Pineau A (1973) Metall Mater Trans A4:47

Kegg CR, Silcock JM (1972) Scripta Metall 6:1083

Lewis MH, Hatterrsley B (1965) Acta Metall 13:1159

Loomis WT, Freeman JW, Sponseller DL (1964) Metall Mater Trans A67:714

Jones RD, Kapoor S (1973) J Iron Steel Inst 211:226

Peters DT (1967) Trans TMS-AIME 239:1981

Allen D, Keustermans JP, Grijbels S, Bicego V (2004) Mater High Temp 21:53

Mankins WL, Hoster JC, Bassford TH (1974) Metall Trans 5:2593

Rao GA, Prasad KS, Kumar M, Srinivas M, Sarma DS (2003) J Mater Sci Technol 19:1

Rao GA, Kumar M, Srinivas M, Sarma DS (2003) Mater Sci Eng A355:114

Lewis MH, Hattersley B (1965) Acta Metall 13:1159

Garzarotli F, Gerscha A, Francke FP (1969) Z Metallkunde 60:643

Sundararaman M, Mukhopadhyaya P, Benerjee S (1988) Mater Sci Forum 3:453

Shankar V, Shankara Rao KB, Mannan SL (2001) J Nucl Mater 288:222

Sun WR, Guo SR, Lee JH, Park NK, Yoo YS, Choe SJ, Hu ZQ (1998) Mater Sci Eng A247:173

Ferreire I, Stang RG (1983) Acta Metall 31:585

Merrick HF (1995) Metall Mater Trans A7:505

Valencia JJ, Spirko J, Schmees R (1997) In: Loria EA (ed) Superalloys 718, 625, 706 and various derivatives. TMS, Warredale, PA, p 753

Stoloff NS (1989) Int Mater Rev 34:153

Marquez C, Esparane GL, Koul AK (1989) Int J Powder Met 25:301

Maziasz PJ (1989) J Nucl Mater 169:95

Williams TM, Titchmarsh JM (1979) J Nucl Mater, 82:199

Williams TM, Titchmarsh JM (1981) J Nucl Mater 98:223

Chen W, Chaturvedi M (1993) Can Metall Quart 32(4):363

Campo E, Turco C, Catena V (1985) Metall Sci Tech, J. TEKSID, Italy, 3(1):16

Collins HE (1975) Metall Mater Trans 5:187

Kimball OF, Lai GY, Reynolds GH (1976) Metall Trans A 7:1951

Qiu YY (1996) J All Comp 232:254

Chen W, Chaturvedi M (1994) Mater Sci Eng A183:81

Xue H, Lijun W, Hui X, Runguang L, Shaogang W, Zhonglin C (2003) J Mater Proc Techn 137:17

Betteridge W, Franklin AW (1957) J Inst Met 85:473

Devine TM (1990) Corrosion Sci 30:135

Mathew MD, Sasikala G, Bhanu Sankara Rao K, Mannan SL (1991) Mater Sci Eng A148:253

Iacoviello F, Casari F, Gialanella F (2005) Corros Sci 47:909

Park C-J, Ahn M-K, Kwon H-S (2006) Mater Sci Eng A418:211

Dahotre NB, McCay MH, McCay TD, Hubbard CR, Porter WD, Cavin OB (1993) Scripta Metall Mater 28:1359

Evans ND, Maziasz PJ, Swindeman RW, Smith GD (2004) Scripta Mater 51:503

Zhao S, Xie X, Smith GD, Patel SJ (2003) Mater Sci Eng A355:96

Kindrachuk V, Wanderka N, Banhart J (2006) Mater Sci Eng A417:82

Murakumo T, Kobayashi T, Koizumi Y, Harada H (2004) Acta Mater 52:3737

Shubert F, Bruch U, Cook R, Diehl H, Ennis PJ, Jakobeit W, Penkalla E, Ullrich G (1984) Nucl Technol 66:227

Rai SK, Kumar A, Shankar V, Jayakurmar T, Rao KBS, Raj B (2004) Scripta Mater 51:59

Yuan H, Liu WC (2005) Mater Sci Eng A408:281

Liu L, Zhai C, Lu C, Ding W, Hirose A, Kobayashi KF (2005) Corros Sci 47:255

Azadian S, Wei L-Y, Warren R (2004) Mater Charact 53:7

Acknowledgements

The authors are grateful to the other Italian creep laboratories, which contributed to the experimental creep test program (CESI (Piacenza, Milan), ISB (Milan) and CSM (Rome)). Thanks are also due to all the members of the WG3C of ECCC for their support and stimulating discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cabibbo, M., Gariboldi, E., Spigarelli, S. et al. Creep behavior of INCOLOY alloy 617. J Mater Sci 43, 2912–2921 (2008). https://doi.org/10.1007/s10853-007-1803-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1803-7