Abstract

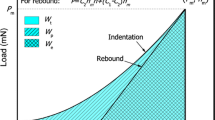

Cyclic indentation was used to evaluate the dynamic deformation of aluminum. Under the load-controlled cyclic indentation, the indenter continuously penetrated into the material and reached a steady state at which the penetration speed (per cycle) was a constant. The amplitude of the cyclic indentation depth was basically controlled by the amplitude of the cyclic indentation load, independent of the mean indentation load and the indentation frequency. The steady state penetration speed decreased with increasing the amplitude of the cyclic indentation load due to the increase in the size of plastic zone. It also decreased with the increase in the mean indentation load due to local strain hardening, while it increased with the increase of the indentation frequency.

Similar content being viewed by others

References

Klesnil M, Lukas P (1980) Fatigue of metallic materials. Amsterdam, The Netherlands7 Elsevier Science

Sarfarazi M, Ghosh K (1987) Eng Fract Mech 27:257

Samuels LE (1986) In: Blau PJ, Lawn BR (eds) Microindentation techniques in materials science and engineering, ASTM STP 889. Am. Soc. Testing and Mater., Philadelphia, pp 5–25

Yang FQ, Jiang CB, Du WW, Zhang ZQ, Li SX, Mao SX (2005) Nanotechnology 16:1073

Vaughan DAJ, Guiu F (1887) Brit Ceram Proc 39:101

Reece M, Guiu F (1991) J Am Ceram Soc 74:148

Takakura E, Horibe S (1992) J Mater Sci 27:6151

Guillou M-O, Henshall JL, Hooper RM (1993) J Am Ceram Soc 76:1832

Henshall JL, Guillou M-O, Hooper RM (1996) Fatigue Fract Eng Mater Struct 19:903

Guiberteau F, Padture NP, Cai H, Lawn BR (1993) Phil Mag A 68:1003

Cai H, Kalceff MAS, Hooks BM, Lawn BR, Chyung K (1994) J Mater Res 9:2654

Padture NP, Lawn BR (1995) J Am Ceram Soc 78:1431

Kim DK, Jung Y-G, Peterson 1M, Lawn BR (1999) Acta Mater 42:4711

Ann L (1999) J Am Ceram Soc 82:178

Li JCM, Chu SNG (1979) Scripta Metall 13:1021

Chu SNG, Li JCM (1980) J Eng Mater Tech Trans ASME 102:337

Loubet JL, Georges JM, Meille G (1986) In: Blau PJ, Lawn BR (eds) Vickers indentation curves of elastoplastic materials, ASTM STP 889. Am. Soc. Testing and Mater., Philadelphia, pp 72–89

Sneddon IN (1992) Quart J Mech Appl Math 45:607

Suresh S (1998) Fatigue of materials, 2nd edn. Cambridge University Press

Cheng YT, Cheng CM (2004) Mater Sci Eng R44:91

Yang FQ, Peng LL, Okazaki K (2004) Metal Mater Trans A 35:3323

Hill R (1950) The mathematical theory of plasticity. Clarendon Press, Oxford

Johnson KL (1970) J Mech Phys Solids 18:115

Yang FQ, Peng LL, Okazaki K (2004) J Mater Res 19:1243

Acknowledgments

This research is supported by NSF through a grant CMS-0508989 and Kentucky Science and Engineering Foundation through a grant KSEF-148-502-03-73.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Peng, L. & Okazaki, K. Cyclic indentation in aluminum. J Mater Sci 42, 4513–4520 (2007). https://doi.org/10.1007/s10853-006-0480-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0480-2