Abstract

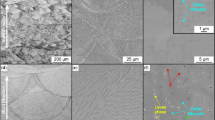

In order to investigate the influence of the preparation method on the electrochemical dissolution behavior of the typical superalloy Inconel 718, we employed various test methods to determine the composition and structure of the passive film. Test results show that the film is mainly composed of Cr2O3 and NiO, which have an obvious impact on the electrochemical and physical properties of the surface. The electrochemical machining experiments indicate that wrought Inconel 718 contains large amounts of pitting and selective corrosion, while hot-rolled Inconel 718 exhibits finer grains and a more uniform distribution, which results in a more even dissolution and a better surface quality.

Graphical abstract

Similar content being viewed by others

Data availability

All data recorded/measured during this research are available from the corresponding author on reasonable request.

References

Rahman M, Seah WKH, Teo TT (1997) The machinability of inconel 718. J Mater Process Technol 63:199–204

Damodaram R, Raman SGS, Satyanarayana DVV, Reddy GM, Rao KP (2014) Hot tensile and stress rupture behavior of friction welded alloy 718 in different pre-and post-weld heat treatment conditions. Mater Sci Eng A 612:414–422. https://doi.org/10.1016/j.msea.2014.06.076

Karabela A, Zhao LG, Tong J, Simms NJ, Nicholls JR, Hardy MC (2011) Effects of cyclic stress and temperature on oxidation damage of a nickel-based superalloy. Mater Sci Eng A 528:6194–6202. https://doi.org/10.1016/j.msea.2011.04.029

Fujisawa T, Inaba K, Yamamoto M, Kato D (2008) Multiphysics simulation of electrochemical machining process for three-dimensional compressor blade. J Fluids Eng 130:081602. https://doi.org/10.1115/1.2956596

Klocke F, Zeis M, Klink A (2012) Technological and economical capabilities of manufacturing titanium- and nickel-based alloys via Electrochemical Machining (ECM). In: Merklein M, Hagenah H (eds) Material Forming—Esaform 2012, Pts 1 & 2. Trans Tech Publications Ltd, Zurich, pp 1237–1242. https://doi.org/10.4028/www.scientific.net/KEM.504-506.1237

Rajurkar KP, Zhu D, McGeough JA, Kozak J, Silva AD (1999) New developments in electro-chemical machining. CIRP Ann. https://doi.org/10.1016/S0007-8506(07)63235-1

Xu ZY, Xu Q, Zhu D, Gong T (2013) A high efficiency electrochemical machining method of blisk channels. CIRP Ann 62:187–190. https://doi.org/10.1016/j.cirp.2013.03.068

Zhang JC, Xu ZY, Zhu D, Su WF, Zhu D (2017) Study of tool trajectory in blisk channel ECM with spiral feeding. Mater Manuf Processes 32:333–338. https://doi.org/10.1080/10426914.2016.1151040

Zhang SL, Liu JR, Lin X, Huang YH, Wang M, Zhang YF, Qin T, Huang WD (2021) Effect of electrolyte solutions on the electrochemical dissolution behavior of additively manufactured Hastelloy X superalloy via laser solid forming. J Alloys Compd 878:160395. https://doi.org/10.1016/j.jallcom.2021.160395

Zhou F, Duan W, Li X, Tsai J-T, Jun MBG (2021) High precision in-situ monitoring of electrochemical machining process using an optical fiber Fabry-Pérot interferometer sensor. J Manuf Mater Process 68:180–188. https://doi.org/10.1016/j.jmapro.2021.07.010

Wang DY, Zhu ZW, Wang NF, Zhu D, Wang HR (2015) Investigation of the electrochemical dissolution behavior of Inconel 718 and 304 stainless steel at low current density in NaNO3 solution. Electrochim Acta 156:301–307. https://doi.org/10.1016/j.electacta.2014.12.155

Wang ML, Qu NS (2020) Electrochemical dissolution behavior of S-04 high-strength stainless steel in NaNO3 aqueous solution. J Appl Electrochem 50:1149–1163. https://doi.org/10.1007/s10800-020-01469-2

Feng SN, Gong JH, Li HX, Wang HR (2018) Effect of heat treatment process on hardness and corrosion resistance of GH4169. Mater Sci Eng 452:022089. https://doi.org/10.1088/1757-899X/452/2/022089

Yang J, Wu J, Zhang CY, Zhang SD, Yang BJ, Emori W, Wang JQ (2020) Effects of Mn on the electrochemical corrosion and passivation behavior of CoFeNiMnCr high-entropy alloy system in H2SO4 solution. J Alloys Compd 819:152943. https://doi.org/10.1016/j.jallcom.2019.152943

Wang Y, Xu Z, Zhang A (2020) Anodic characteristics and electrochemical machining of two typical γ-TiAl alloys and its quantitative dissolution model in NaNO3 solution. Electrochim Acta 331:135429. https://doi.org/10.1016/j.electacta.2019.135429

Tang Y, Xu ZY (2018) The electrochemical dissolution characteristics of GH4169 nickel base super alloy in the condition of electrochemical machining. Int J Electrochem Sci 13:1105–1119. https://doi.org/10.20964/2018.01.75

Yang FF, Kang HJ, Chen ZN, Guo EY, Zeng YY, Wang W, Wang TM (2019) Electrochemical corrosion mechanisms of nickel-aluminium bronze with different nickel contents using the rotating disc electrode. Corros Sci 157:438–449. https://doi.org/10.1016/j.corsci.2019.06.018

El-Taib HF, Ghoneim AA, Mogoda AS, Awad K (2011) Electrochemical behaviour of Ti-6Al-4V alloy and Ti in azide and halide solutions. Corros Sci 53:2728–2737. https://doi.org/10.1016/j.corsci.2011.05.003

Haisch T, Mittemeijer E, Schultze JW (2001) Electrochemical machining of the steel 100Cr6 in aqueous NaCl and NaNO3 solutions: microstructure of surface films formed by carbides. Electrochim Acta 47:235–241

Schneide MR, Schuber NT, Hoehn S, Michaelis A (2013) Anodic dissolution behaviour and surface texture development of cobalt under electrochemical machining conditions. Electrochim Acta 106:279–287. https://doi.org/10.1016/j.electacta.2013.05.070

Kadowaki M, Muto I, Takahashi K, Doi T, Masuda H, Katayama H, Kawano K, Sugawara Y, Hara N (2019) Anodic Polarization Characteristics and Electrochemical Properties of Fe3C in Chloride Solutions. J Electrochem Soc C 166:345–351. https://doi.org/10.1149/2.1311912jes

Hosseini E, Popovich VA (2019) A review of mechanical properties of additively manufactured Inconel 718. Addit Manuf 30:100877. https://doi.org/10.1016/j.addma.2019.100877)100877)100877

Tabaie S, Rézaï-Aria F, Flipo BCD, Jahazi M (2022) Dissimilar linear friction welding of selective laser melted Inconel 718 to forged Ni-based superalloy AD730™: evolution of strengthening phases. J Mater Sci Technol 96:248–261. https://doi.org/10.1016/j.jmst.2021.03.086

Chen Z, Zhang G, Yang E-H (2018) Study of steel corrosion in strain-hardening cementitious composites (SHCC) via electrochemical techniques. Electrochim Acta 261:402–411. https://doi.org/10.1016/j.electacta.2017.12.170

Wang MQ, Zhou ZH, Wang QJ, Wang ZH, Zhang X, Liu YY (2019) Role of passive film in dominating the electrochemical corrosion behavior of FeCrMoCBY amorphous coating. J Alloys Compd 811:151962. https://doi.org/10.1016/j.jallcom.2019.151962

Liao CJ, Liu Q, Ma XZ, Liu JH (2019) relationship between surface heterogeneity and electrochemical interface behavior of the TiAl alloy electrode. J Phys Chem C 123:473–484. https://doi.org/10.1021/acs.jpcc.8b09123

Huang J, Li Z, Liaw BY, Zhang J (2016) Graphical analysis of electrochemical impedance spectroscopy data in Bode and Nyquist representations. J Power Sources 309:82–98. https://doi.org/10.1016/j.jpowsour.2016.01.073

Deutsch (2020) Electrochemical Impedance Spectroscopy and its Applications. Springer, New York. https://doi.org/10.1007/978-1-4614-8933-7

Poddar C, Ningshen S, Jayaraj J (2020) Corrosion assessment of Ni-60 Nb30Ta10 metallic glass and its partially crystallized alloy in concentrated nitric acid environment. J Alloys Compd 813:152172. https://doi.org/10.1016/j.jallcom.2019.152172

Obeydavi A, Shafyei A, Rezaeian A, Kameli P, Lee J-W (2020) Microstructure mechanical properties and corrosion performance of Fe44Cr15Mo14Co7C10B5Si5 thin film metallic glass deposited by DC magnetron sputtering. J Non-Cryst Solids 527:119718. https://doi.org/10.1016/j.jnoncrysol.2019.119718

Liu L, Li Y, Wang FH (2007) Influence of micro-structure on corrosion behavior of a Ni-based superalloy in 3.5% NaCl. Electrochim Acta 52:7193–7202. https://doi.org/10.1016/j.electacta.2007.05.043

Lu YS, Lu CW, Lin YT, Yen HW, Lee YL (2020) Corrosion behavior and passive film characterization of Fe50Mn30Co10Cr10 dual-phase high-entropy alloy in sulfuric acid solution. J Electrochem Soc 167:081506. https://doi.org/10.1149/1945-7111/ab8de4

Acknowledgements

This work was supported by the Natural Science Foundation of Anhui Province (Grant No. 2008085QE250); the Natural Science Foundation of Jiangsu Province (Grant No. BK20190419); and the China Postdoctoral Science Foundation (Grant No. 2018M642246).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Song, S., Li, X. et al. Study of the influence of the preparation method on the electrochemical dissolution behavior of Inconel 718. J Appl Electrochem 52, 1149–1162 (2022). https://doi.org/10.1007/s10800-022-01693-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-022-01693-y