Abstract

Ground improvement by the construction of stone columns has been widely adopted. This paper presents the results of an experimental study on ordinary and encased stone columns, made of different mix proportions of stone aggregates and shredded tyre chips, subjected to sustained loading, i.e., simulating long-term drained loading conditions. The load was applied in increments and each load increment was applied once the settlement became constant after considerable time under the previous load increment. Results showed a pronounced increase in ultimate load-carrying capacity of such columns as compared to that of pure clay bed, even when the columns were partially made of shredded tyre chips, with remarkable enhancement evident in encased columns. Comparative analysis revealed that these columns under sustained loading performed better than those under quick loading. The surcharge effect with drainage of pore water was evident under sustained loading. ‘Efficiency’ factor of columns was evaluated to examine the enhancement of load-carrying capacities of such columns with respect to conventional columns and to arrive at optimum/feasible mix proportions composing the columns. A study of the ‘efficiency’ factor showed replacement of about 50% of stone aggregates with shredded tyre chips is possible in encased columns under sustained loading for all encasing materials tested. However, considering the corrosion of galvanized wire mesh over time, geosynthetics was found to be the efficient encasement material.

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

Abbreviations

- 100S:

-

100% Stone aggregates

- 70S + 30T:

-

70% Stone aggregates + 30% shredded tyre chips

- 50S + 50T:

-

50% Stone aggregates + 50% shredded tyre chips

- 30S + 70T:

-

30% Stone aggregates + 70% shredded tyre chips

- 100T:

-

100% Shredded tyre chips

- SOSCs:

-

Ordinary Stone Columns under Sustained loading

- SGESCs:

-

Geonet Encased Columns under Sustained loading

- SWESCs:

-

Galvanized Wire-Mesh Encased Columns under Sustained loading

- SIESCs:

-

Steel nails-Reinforced Columns under Sustained loading

- Q :

-

Safe load on column and tributary soil

- Q 1 :

-

Safe load on column area alone

- Q 2 :

-

Load-carrying capacity due to surcharge effect

- Q 3 :

-

Bearing support provided by intervening soil

References

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305

Ali K, Shahu JT, Sharma KG (2014) Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth Int 21(2):103–118

Almeida MS, Hosseinpour I, Riccio M, Alexiew D (2015) Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J Geotech Geoenviron Eng 141(3):04014116

Amini, R. (2016). Physical modelling of vibro stone column using recycled aggregates (Doctoral dissertation, University of Birmingham).

Annam MK (2011) Practical applications of ground improvement. One Day Workshop on Ground Improvement using Vibro Techniques, Tanjavur, Tamil Nadu, India

Ayothiraman R, Soumya S (2015) Model tests on the use of tyre chips as aggregate in stone columns. Proc Inst Civ Eng-Ground Improv, London 168(3):187–193

Bergado DT, Lam FL (1987) Full scale load test of granular piles with different densities and different proportions of gravel and sand on soft Bangkok clay. Soils Found 27(1):86–93

Castro J (2014) An analytical solution for the settlement of stone columns beneath rigid footings. Acta Geotech 11:309–324

Castro J (2017) Groups of encased stone columns: influence of column length and arrangement. GeotextGeomembr 45(2):68–80

Castro J, Sagaseta C (2011a) Deformation and consolidation around encased stone columns. Geotext Geomembr 29(3):268–276

Castro J, Sagaseta C (2011b) Deformation and consolidation around encased stone columns. GeotextGeomembr 29(3):268–276

Chen JF, Wang XT, Xue JF, Zeng Y, Feng SZ (2018) Uniaxial compression behavior of geotextile encased stone columns. Geotext Geomembr 46(3):277–283

Das AK, Deb K (2017) Modelling of stone column-supported embankment under axi-symmetric condition. Geotech Geol Eng 35(2):707–730

Dash SK, Bora MC (2013) Improved performance of soft clay foundations using stone columns and geocell-sand mattress. Geotext Geomembr 41:26–35

Debnath P, Dey AK (2017a) Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay. Geotext Geomembr 45(6):653–664

Debnath P, Dey AK (2017b) Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay. GeotextGeomembr 45(6):653–664

Foose GJ, Benson CH, Bosscher PJ (1996) Sand reinforced with shredded waste tires. J Geotech Eng 122(9):760–767

Ghazavi M, Afshar JN (2013) Bearing capacity of geosynthetic encased stone columns. Geotext Geomembr 38:26–36

Ghazavi M, Yamchi AE, Afshar JN (2018) Bearing capacity of horizontally layered geosynthetic reinforced stone columns. Geotext Geomembr 46(3):312–318

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. Geotext Geomembr 27(3):167–175

Gotteland P, Lambert S, Balachowski L (2005) Strength characteristics of tyre chips-sand mixtures. Studia Geotechnica Et Mechanica 27(1–2):55–66

Greenwood DA (1970) Mechanical improvement of soils below ground surfaces. In: Proceedings Ground Engineering Conference, Institution of Civil Engineers, London, pp 11–22.

Gu M, Han J, Zhao M (2017) Three-dimensional DEM analysis of single geogrid encased stone columns under unconfined compression: a parametric study. Acta Geotech 12(3):559–572

Han J, Ye S (1993) Field study of an oil tank on stone column ground. In: The Third International Conference on Case Histories in Geotechnical Engineering, St. Louis, MO, USA.

Hazarika H, Yasuhara K, Kikuchi Y, Karmokar AK, Mitarai Y (2010) Multifaceted potentials of tire-derived three dimensional geosynthetics in geotechnical applications and their evaluation. Geotext Geomembr 28(3):303–315

Hughes JM, Withers NJ, Greenwood DA (1975) A field trial of reinforcing effect of stone column in soil. Geotechnique 25(1):32–44

Indian Standard (IS):1498 (1970) Classification and Identification of Soils for General Engineering Purposes. Bureau of Indian Standards, New Delhi, India

Indian Standard (IS):15284 (Part-1) (2003) Design and Construction for Ground Improvement–Guidelines, Part 1: Stone Columns. Bureau of Indian Standards, New Delhi, India.

Indian Standard (IS): 2911(Part 4) (1985)Code of practice for design and construction of pile foundations-load tests on piles. Bureau of Indian Standards, New Delhi, India

Lillis C, Lutenegger AJ, Adams M (2004) Compression and uplift of rammed aggregate piers in clay. In GeoSupport 2004: Drilled Shafts, Micropiling, Deep Mixing, Remedial Methods, and Specialty Foundation Systems, pp 497–507.

Lo SR, Zhang R, Mak J (2010) Geosynthetic-encased stone columns in soft clay: a numerical study. Geotext Geomembr 28(3):292–302

Masad E, Taha R, Ho C, Papagiannakis T (1996) Engineering properties of tire/soil mixtures as a lightweight fill material. Geotech Test J 19(3):297–304

Mashiri MS, Vinod JS, Sheikh MN, Tsang HH (2015) Shear strength and dilatancy behaviour of sand–tyre chip mixtures. Soils Found 55(3):517–528

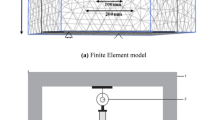

Mazumder T, Ayothiraman R (2021) Numerical study on behaviour of encased stone columns with partial content of shredded tyre chips in soft clay bed. Int J Geosynth and Ground Eng 7:31. https://doi.org/10.1007/s40891-021-00280-z

Mazumder T, Rolaniya AK, Ayothiraman R (2018) Experimental study on behaviour of encased stone column with tyre chips as aggregates. Geosynth Int 25(3):259–270

McCabe BA, Nimmons GJ, Egan D (2009) A review of field performance of stone columns in soft soils. Proc Inst Civ Eng-Geotech Eng 162(6):323–334

Miranda M, CostaA Da, Castro J, Sagaseta C (2017) Influence of geotextile encasement on the behaviour of stone columns: Laboratory study. Geotext Geomembr 45(1):14–22

Murugesan S, Rajagopal K (2006) Geosynthetic-encased stone columns: numerical evaluation. Geotext Geomembr 24(6):349–358

Murugesan S, Rajagopal K (2010) Studies on the behavior of single and group of geosynthetic encased stone columns. J Geotech Geoenviron Eng 136(1):129–139

Perez JL, Kwok CY, Senetakis K (2016) Effect of rubber size on the behaviour of sand-rubber mixtures: a numerical investigation. Comput Geotech 80:199–214

Pulko B, Majes B, Logar J (2011) Geosynthetic-encased stone columns: analytical calculation. Geotext Geomembr 29(1):29–39

Reddy SB, Pradeep DK, Krishna AM (2016) Evaluation of the optimum mixing ratio of a sand-tire chips mixture for geoengineering applications. J Mater Civ Eng 28(2):06015007

Shahverdi M, Haddad A (2020) Use of recycled materials in floating stone columns. Proc Inst Civ Eng-Constr Mater 173(2):99–108

Shivashankar R, Babu MD, Nayak S, Manjunath R (2010) Stone columns with vertical circumferential nails: laboratory model study. Geotech Geol Eng 28(5):695–706

Tiwari SK, Sharma JP, Yadav JS (2017) Geotechnical properties of dune sand-waste tires composite. Mater TOday: Proc 4(9):9851–9855

Wood DM (2004) Geotechnical modelling, 2nd edn. CRC Press, Taylor and Francis Group

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mazumder, T., Neeraj, N. & Ayothiraman, R. Study of Behavior of Encased Columns Composed of Shredded Tyre Chips and Stone Aggregates in Kaolinite Clay Bed. Geotech Geol Eng 41, 3733–3751 (2023). https://doi.org/10.1007/s10706-023-02484-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02484-8