Abstract

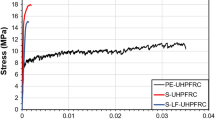

In this work we assess the effect of the addition of polypropylene (PP) fibers in a heated ultra-high-performance fiber reinforced concrete (UHPFRC). To this end, three sets of specimens with identical cementitious materials were manufactured: plain concrete, a concrete reinforced exclusively with steel fibers and a concrete reinforced with steel and polypropylene fibers. The mechanical and fracture properties of each concrete at temperatures ranging from room temperature to \(300\,^\circ \)C were determined. A thorough appraisal of the thermal effect on the microstructure was also carried out by means of an X-ray scan analysis. Based on the testing data, the relation between the macroscopic response, including mechanical and fracture behavior, and the microscopic structure, i.e., size and number of pores and their distribution, is ascertained. The results show that the addition of PP fibers significantly increases the maximum pore size and slightly increases the total porosity. Furthermore, the partial melting of polypropylene fibers at \(300\,^\circ \)C, in combination with the rise in porosity, reduces thermal damage and results in similar behavior at low and high temperatures, room temperature and \(300\,^\circ \)C, respectively.

Similar content being viewed by others

References

Abrishambaf A, Pimentel M, Nunes S (2017) Influence of fibre orientation on the tensile behaviour of ultra-high performance fibre reinforced cementitious composites. Cem Concr Res 97:28–40

American Concrete Institute (1996) 544.1R-96: Report on Fiber Reinforced Concrete

Akca AH, Özyurt N (2018) Effects of re-curing on residual mechanical properties of concrete after high temperature exposure. Construct Build Mater 159:540–552

Akca AH, Zihnioglu NO (2013) High performance concrete under elevated temperatures. Construct Build Mater 44:317–328

Al-Azzawi BS, Karihaloo BL (2017) Mechanical and fracture properties of a self-compacting version of CARDIFRC Mix II. Sadhana 42:5

Alberti M, Enfedaque A, Galvez J, Reyes E (2017) Numerical modelling of the fracture of polyolefin fibre reinforced concrete by using a cohesive fracture approach. Compos Part B 111:200–210

Alonso MC, Fernandez L (2004) Dehydration and rehydration processes of cement paste exposed to high temperature environments. J Mater Sci 39(9):3015–3024

Alyhya WS, Dhaheer MSA, Al-Rubaye MM, Karihaloo BL (2016) Influence of mix composition and strength on the fracture properties of self-compacting concrete. Construct Build Mater 110:312–322

ASTM International C 1018-97 (2002) Standard test method for flexural toughness and first-crack strength of fiber-reinforced concrete (using beam with third-point loading). ASTM annual book of standards

Awinda K, Chen J, Barnett S, Fox D (2014) Modelling behaviour of ultra high performance fibre reinforced concrete. Adv Appl Ceram 113(8):502–508

Barros JAO, Cruz JS (2001) Fracture energy of steel fiber-reinforced concrete. Mech Compos Mater Struct 8(1):29–45

Bazant ZP, Planas J (1998) Fracture and size effect in concrete and other quasi brittle materials. CRC Press, Boca Raton

Bilodeau A, Kodur VKR, Hoff GC (2004) Optimization of the type and amount of polypropylene fibres for preventing the spalling of lightweight concrete subjected to hydrocarbon fire. Cem Concr Compos 26(2):163–174

Canteli A, Castanon-Jano L, Cifuentes H, Muniz-Calvente M, Castillo E (2017) Fitting the fracture curve of concrete as a density function pertaining to the generalized extreme value family. Mater Design 129:201–209

Cifuentes H, Leiva C, Medina F, Fernández-Pereira C (2012) Effects of fibres and rice husk ash on properties of heated HSC. Magaz Concr Res 64(5):457–470

Deeb R, Karihaloo BL (2012) Development of self-compacting high and ultra high performance concretes with and without steel fibres. Cem Concr Compos 34(2):185–190

EN-12390-13:2014 (2014) Testing hardened concrete Part 13: Determination of secant modulus of elasticity in compression. AENOR

EN-12390-3 (2009) Testing hardened concrete Part 3: Compressive strength of test specimens. AENOR

Erdoğan S, Garboczi E, Fowler D (2007) Shape and size of microfine aggregates: X-ray microcomputed tomography vs. laser diffraction. Powder Thecnol 177:53–63

Garboczi EJ (2002) Three-dimensional mathematical analysis of particle shape using X-ray tomography and spherical harmonics: application to aggregates used in concrete. Cem Concr Res 32(10):1621–1638

Hillerborg A, Modéer M, Petersson PE (1976) Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concr Res 6(6):773–781

Hwang JP, Kim M, Ann KY (2015) Porosity generation arising from steel fibre in concrete. Construct Build Mater 94:433–436

Jiang C, Fan K, Wu F, Chen D (2014) Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater Design 58:187–193

Khosravani MR, Silani M, Weinberg K (2018) Fracture studies of ultra-high performance concrete using dynamic Brazilian tests. Theor Appl Fract Mech 93:302–310

Kim KY, Yun TS, Choo J, Kang DH, Shin HS (2012) Determination of air-void parameters of hardened cement-based materials using X-ray computed tomography. Construct Build Mater 37:93–101

Kim MJ, Kim S, Lee SK, Kim JH, Lee K, Yoo DY (2017) Mechanical properties of ultra-high-performance fiber-reinforced concrete at cryogenic temperatures. Construct Build Mater 157:498–508

Kumar R, Bhattacharjee B (2003) Porosity, pore size distribution and in situ strength of concrete. Cem Concr Res 33(1):155–164

Lian C, Zhuge Y, Beecham S (2011) The relationship between porosity and strength for porous concrete. Construct Build Mater 25(11):4294–4298

Liu X, Ye G, Schutter GD, Yuan Y, Taerwe L (2008) On the mechanism of polypropylene fibres in preventing fire spalling in self-compacting and high-performance cement paste. Cem Concr Res 38(4):487–499

López JA, Serna P, Navarro-Gregori J, Coll H (2016) A simplified five-point inverse analysis method to determine the tensile properties of UHPFRC from unnotched four-point bending tests. Compos Part B 91:189–204

Mao L, Barnett S, Begg D, Schleyer G, Wight G (2014) Numerical simulation of ultra high performance fibre reinforced concrete panel subjected to blast loading. Int J Impact Eng 64:91–100

Mao L, Yuan Z, Yang M, Liu H, pen Chiang F (2019) 3D strain evolution in concrete using in situ X-ray computed tomography testing and digital volumetric speckle photography. Measurement 133:456–467

van Mier JGM (1997) Fracture processes of concrete. CRC Press, Boca Raton

Moradian M, Hu Q, Aboustait M, Ley MT, Hanan JC, Xiao X, Scherer GW, Zhang Z (2017) Direct observation of void evolution during cement hydration. Mater Design 136:137–149

Moradian M, Ley MT, Grasley ZC (2018) Stress induced dissolution and time-dependent deformation of portland cement paste. Mater Design 157:314–325

Murthy AR, Karihaloo BL, Iyer NR, Prasad BKR (2013) Bilinear tension softening diagrams of concrete mixes corresponding to their size-independent specific fracture energy. Construct Build Mater 47:1160–1166

Neville A (2011) Properties of concrete, 5th edn. Pearson Education Limited, England

Park K, Paulino GH, Roesler J (2010) Cohesive fracture model for functionally graded fiber reinforced concrete. Cem Concr Res 40(6):956–965

Ponikiewski T, Katzer J, Budgol M, Rudzki M (2014) Determination of 3d porosity in steel fibre reinforced scc beams using X-ray computed tomography. Constr Build Mater 68:333–340

Poveda E, Ruiz G, Cifuentes H, Yu RC, Zhang X (2017) Influence of the fiber content on the compressive low-cycle fatigue behavior of self-compacting SFRC. Int J Fatigue 101:9–17

Ramezanianpour AA, Esmaeili M, Ghahari SA, Najafi MH (2013) Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Construct Build Mater 44:411–418

RILEM-TCM85 (1985) Determination of the fracture energy of mortar and concrete by means of three-point bend tests on notched beams. Mater Struct 18(4):287–290

Ríos JD, Cifuentes H, Leiva C, García C, Alba M (2017) Behavior of high-strength polypropylene fiber-reinforced self-compacting concrete exposed to high temperatures. J Mater Civil Eng 30:11

Ríos JD, Cifuentes H, Leiva C, Seitl S (2019) Analysis of the mechanical and fracture behavior of heated ultra-high-performance fiber-reinforced concrete by X-ray computed tomography. Cem Concr Res 119:77–88

Ríos JD, Cifuentes H, Yu RC, Ruiz G (2017) Probabilistic flexural fatigue in plain and fiber-reinforced concrete. Materials 10:7

Ríos JD, Leiva C, Ariza MP, Seitl S, Cifuentes H (2019) Analysis of the tensile fracture properties of ultra-high-strength fiber-reinforced concrete with different types of steel fibers by X-ray tomography. Mater Design 165:14

Ruiz G, Ortiz M, Pandolfi A (2000) Three-dimensional finite-element simulation of the dynamic brazilian tests on concrete cylinders. Int J Numer Methods Eng 48(7):963–994

Ruiz G, Pandolfi A, Ortiz M (2001) Three-dimensional cohesive modeling of dynamic mixed-mode fracture. Int J Numer Methods Eng 52:97–120

Sahin Y, Köksal F (2011) The influences of matrix and steel fibre tensile strengths on the fractureenergy of high-strength concrete. Construct Build Mater 25:1801–1806

Scrivener KL, Crumbie AK, Laugesen P (2004) The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci 12(4):411–421

Simoes T, Costa H, da Costa DD, Júlio E (2017) Influence of fibres on the mechanical behaviour of fibre reinforced concrete matrixes. Construct Build Mater 137:548–556

Sokhansefat G, Ley MT, Cook MD, Alturki R, Moradian M (2019) Investigation of concrete workability through characterization of aggregate gradation in hardened concrete using X-ray computed tomography. Cem Concr Compos 98:150–161

Suarez F, Galvez J, Enfedaque A, Alberti M (2019) Modelling fracture on polyolefin fibre reinforced concrete specimens subjected to mixed-mode loading. Eng Fract Mech 211:244–253

Tejchman J, Bobinski J (2013) Continuous and discontinuous modelling of fracture in concrete using FEM. Springer, Berling

Trawinski W, Tejchman J, Bobinski J (2019) A three-dimensional meso-scale modelling of concrete fracture, based on cohesive elements and X-ray CT images. Eng Fract Mech 189:27–50

Vicente MA, González DC, Mínguez J, Tarifa M, Ruiz G, Hindi R (2018) Influence of the pore morphology of high strength concrete on its fatigue life. Int J Fatigue 112:106–116

Wang R, Gao X, Zhang J, Han G (2018) Spatial distribution of steel fibers and air bubbles in UHPC cylinder determined by X-ray ct method. Construct Build Mater 160:39–47

Yoo DY, Banthia N (2016) Mechanical properties of ultra-high-performance fiber-reinforced concrete: a review. Cem Concr Compos 73:267–280

Zhang B, Bicanic N (2006) Fracture energy of high-performance concrete at high temperatures up to \(450\,^{\circ }{\rm C}\): the effects of heating temperatures and testing conditions (hot and cold). Magaz Concr Res 58(5):277–288

Zhang W, Min H, Gu X, Xi Y, Xing Y (2015) Mesoscale model for thermal conductivity of concrete. Construct Build Mater 98:8–16

Acknowledgements

This research has been funded by the Ministerio de Economía y Competitividad of Spain under grant numbers BIA2016-75431-R and DPI2015-66534-R.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ríos, J.D., Cifuentes, H., Leiva, C. et al. Effect of polypropylene fibers on the fracture behavior of heated ultra-high performance concrete. Int J Fract 223, 173–187 (2020). https://doi.org/10.1007/s10704-019-00407-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-019-00407-4