Abstract

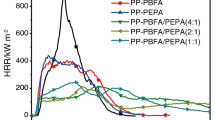

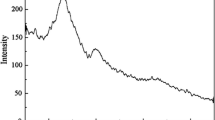

Combinations between poly(pentabromobenzyl acrylate), and highly pure and surface treated magnesium hydroxide offer improved flame retardant systems for polypropylene block copolymers enabling to reduce significantly the need for high loadings of antimony trioxide used as synergist. According to a series of bench-scale tests, these flame retardant blends are contributing to good melt flow properties, significant increase of thermal dimensional stability and ease to recycle scraps online or at the end of life of plastic parts. Drastic smoke reduction is benefit provided by the presence of magnesium hydroxide. The high molecular weight of poly(pentabromobenzyl acrylate) makes it unlikely to leach out or migrate from plastic parts or to penetrate through the cell membranes of living tissue. The use of ethylene/1-octene copolymers is recommended if high impact properties are required.

Similar content being viewed by others

References

Troitzsch J (2004) Plastic flammability handbook. Hanser, p 10

Grand A, Wilkie CA (2000) Fire retardancy of polymeric materials. Marcel Dekker, p 61

Troitzsch J (2004) Plastic flammability handbook. Hanser, pp 162–163

Montezin F, Cuesta J-M, Crespy A (1997) Flame retardant and mechanical properties of a copolymer PP/PE containing brominated compounds/antimony trioxide blends and magnesium hydroxide or talc. Fire Mater 21:245–252

McLennaghan A (2001) Ethylene-1-octene polyolefin elastomers, the materials of choice for modifying polypropylene. KGK Kautschuk Gummi Kunststoffe 54. Jahrgang, Nr. 10/2001

Weil ED, Levchik SV (2009) Flame retardants for plastics and textiles’ practical applications. Hanser, p 15

Dufton PW (1998) Functional additives for the plastics industry. Rapra Technology LTD. p 51

Hull TR, Willis CL, Artingstall T, Price D, Milnes J (2005) Fire retardancy of polymers—new applications of mineral fillers. The Royal Society of Chemistry, p 383

Maier C, Calafut T (1998) Polypropylene: the definitive user’s guide and databook. Plastics Design Library, p 38

Weil ED, Levchik SV (2009) Flame retardants for plastics and textiles’ practical applications. Hanser, p 66

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Melamed, L., Eden, E., Leifer, M. et al. Performances of Blends Between Poly(pentabromobenzyl acrylate) and Magnesium Hydroxide as Flame Retardants for Polypropylene Block Copolymers. Fire Technol 51, 41–52 (2015). https://doi.org/10.1007/s10694-014-0404-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-014-0404-7