Abstract

Cogeneration systems for simultaneous supply of power and hydrogen have been studied extensively because of their great potentials. Accordingly, in the present study, an innovative cogeneration system consisting of a gas turbine, a gasifier, a transcritical Rankine cycle, and a proton exchange membrane electrolyzer is proposed. The system operates on municipal solid waste (MSW) with constant power output. The proposed cogeneration system is simulated under steady-state condition using Engineering Equation Solver (EES) software, and its performance is evaluated from the first and second laws of thermodynamics. The proposed system produced 3.92 MW power and 608.8 m3/h hydrogen under biomass feed of 1.155 kg/s. Under this design condition, the energy utilization factor (EUF), the total exergy efficiency, and the overall exergy destruction rate are calculated 34.71%, 29.44%, and 11,854 kW, respectively. There components of gasifier, gas turbine, and combustion chamber were introduced for owning the highest exergy destruction rate. A comprehensive parametric study was carried out, and it was concluded that the exergy efficiency of condenser has the lowest value among all components. Also, results indicate that the EUF and the total exergy efficiency can be increased by increasing the inlet temperature of the gas turbine or by decreasing the maximum pressure of the transcritical CO2 cycle. In conclusion, the proposed biomass-driven cogeneration system can produce clean electricity and hydrogen by consuming CO2. The strengths of this system are consumption of municipal waste as the main fuel, simplicity in design, as well as high productivity of hydrogen gas.

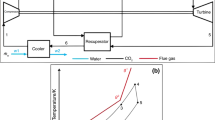

Graphic abstract

Similar content being viewed by others

Abbreviations

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- a :

-

Molar constant of syngas

- \(\overline{R}\) :

-

The global constant of gases (kJ/kmol k)

- e :

-

Specific exergy (kJ/kg)

- \(\overline{s}\) :

-

Molar specific entropy (kJ/kmol k)

- \(\overline{e}\) :

-

Specific exergy (kJ/kmol)

- T :

-

Temperature (K)

- \(\dot{E}\) :

-

Exergy rate (kW)

- V:

-

Electric potential (v)

- E :

-

Input electricity of PEM (K.W.)

- w :

-

Water mole fraction

- F :

-

Faraday constant

- \(\dot{W}\) :

-

Produced electricity (K.W.)

- \(\overline{G}\) :

-

Specific Gibbs free energy (kJ/kmol)

- X :

-

Mole fraction

- h :

-

Specific enthalpy (kJ/kg)

- M:

-

Molar mass (kg/kmol)

- \(\overline{h}\) :

-

Specific enthalpy (kJ/kmol)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- \(J\) :

-

Current density (A/m2)

- \(\dot{n}/\dot{N}\) :

-

Mole flow rate (kmol/s)

- K:

-

Equilibrium constant molar air biomass ratio

- q :

-

Required heat of reaction (kJ/kg)

- m:

-

Molar air biomass ratio

- A.F.:

-

Mass-based air–fuel ratio

- G.T.:

-

Gas turbine

- E.R.:

-

Equivalence ratio

- LHV:

-

Lower heating value (kJ/kg)

- EUF:

-

Energy utilization factor

- MC:

-

Mass-based moisture content

- ν :

-

Specific volume (m3/kg)

- Δ:

-

Difference

- Σ:

-

Summation

- η :

-

Efficiency

- net:

-

Net

- C.V:

-

Control volume

- p:

-

Constant pressure

- CC:

-

Combustion chamber

- ph:

-

Physical

- ch:

-

Chemical

- ref:

-

Reference

- Comp:

-

Compressor

- sto:

-

Stoichiometry

- Des:

-

Destruction

- Syngas:

-

Syngas

- e/out:

-

Outlet

- Sys:

-

System

- eff:

-

Effectiveness

- Tur:

-

Turbine

- Elec:

-

Electrical

- Exh.Gas:

-

Exhaust gases

- 0:

-

Dead state

- f:

-

Formation

- I:

-

The first law of thermodynamic

- F:

-

Fuel

- II:

-

The second law of thermodynamic

- g:

-

Saturated vapor

- a:

-

Anode

- i/in:

-

Inlet

- act:

-

Activation

- is:

-

Isentropic

- AC1:

-

First air compressor

- L:

-

Liquid

- AC2:

-

Second air compressor

- Loss:

-

Loss

- amb:

-

Ambient

References

Al-Sulaiman, F. A., Hamdullahpur, F., & Dincer, I. (2011). Performance comparison of three trigeneration systems using organic Rankine cycles. Energy, 36(9), 5741–5754.

Asgari, N., Khoshbakhti Saray, R., & Mirmasoumi, S. (2020). Energy and exergy analyses of a novel seasonal CCHP system driven by a gas turbine integrated with a biomass gasification unit and a LiBr-water absorption chiller. Energy Conversion and Management, 220, 113096.

Chitgar, N., Emadi, M. A., Chitsaz, A., & Rosen, M. A. (2019). Investigation of a novel multigeneration system driven by a SOFC for electricity and fresh water production. Energy Conversion and Management, 196, 296–310.

Feili, M., Rostamzadeh, H., Parikhani, T., & Ghaebi, H. (2020). Hydrogen extraction from a new integrated trigeneration system working with zeotropic mixture, using waste heat of a marine diesel engine. International Journal of Hydrogen Energy, 45, 21969–21994.

Fiaschi, D., & Carta R. (2007). CO2 abatement by co-firing of natural gas and biomass-derived gas in a gas turbine. Energy, 32(4), 549–567.

Ghiasirad, H., Asgari, N., Khoshbakhti Saray, R., & Mirmasoumi, S. (1399). Geothermal-based freshwater production by humidification-dehumidification and evaporating desalination units integrated with a CCHP system: Energy and exergy analysis. In International Conference on Desalination and Water Treatment, Bandar Abbas. https://civilica.com/doc/1182153.

Ghiasirad, H., Asgari, N., Khoshbakhti Saray, R., & Mirmasoumi, S. (2021). Thermoeconomic assessment of a geothermal based combined cooling, heating, and power system, integrated with a humidification-dehumidification desalination unit and an absorption heat transformer. Energy Conversion and Management, 235, 113969.

Ghiasirad, H., Khoshbakhti Saray, R., Abdi, B., & Bahlouli, K. (2020a). Energy, exergy, and exergo-economic analyses of Urmia sugar factory: a case study of Iran. In 11th Int. chem. eng. congr. exhib., IChEC (p. 6).

Ghiasirad, H., Rostamzadeh, H., & Nasri, S. (2020b) Design and evaluation of a new solar tower-based multi-generation system: Part I, thermal modeling. In: F. Jabari, B. Mohammadi-Ivatloo, & M. Mohammadpourfard (Eds.), Integration of clean and sustainable energy resources and storage in multi-generation systems. Cham: Springer. https://doi.org/10.1007/978-3-030-42420-6_5.

Ghiasirad, H., Rostamzadeh, H., & Nasri, S. (2020c) Design and evaluation of a new solar tower-based multi-generation system: Part II, exergy and exergoeconomic modeling. In: F. Jabari, B. Mohammadi-Ivatloo, & M. Mohammadpourfard (Eds.), Integration of clean and sustainable energy resources and storage in multi-generation systems. Cham: Springer. https://doi.org/10.1007/978-3-030-42420-6_6.

Jayah, T. H., Aye, L., Fuller, R. J., & Stewart, D. F. (2003). Computer simulation of a downdraft wood gasifier for tea drying. Biomass and Bioenergy, 25, 459–469.

Karimi, M. H., Chitgar, N., Emadi, M. A., Ahmadi, P., & Rosen, M. A. (2020). Performance assessment and optimization of a biomass-based solid oxide fuel cell and micro gas turbine system integrated with an organic Rankine cycle. International Journal of Hydrogen Energy, 45, 6262–6277.

Kazemiani-Najafabadi, P., & Amiri, R. E. (2020). Optimizing the bio/natural gas ratio in a dual-fuel gas turbine (DFGT) through energy-economic, environmental, and renewability analyses. Environment, Development and Sustainability, 22, 5371–5386.

Khalid, F., Dincer, I., & Rosen, M. A. (2015). Energy and exergy analyses of a solar-biomass integrated cycle for multigeneration. Solar Energy, 112, 290–299.

Khaljani, M., Saray, R. K., & Bahlouli, K. (2015). Comprehensive analysis of energy, exergy and exergo-economic of cogeneration of heat and power in a combined gas turbine and organic Rankine cycle. Energy Conversion and Management, 97, 154–165.

Kumar, A., Jones, D. D., & Hanna, M. A. (2009). Thermochemical biomass gasification: A review of the current status of the technology. Energies, 2(3), 556–581. https://doi.org/10.3390/en20300556.

Lee, U., Chung, J. N., & Ingley, H. A. (2014). High-temperature steam gasification of municipal solid waste, rubber, plastic and wood. Energy and Fuels, 28(7), 4573–4587.

Mohammadidoust, A., & Omidvar, M. R. (2020). Simulation and modeling of hydrogen production and power from wheat straw biomass at supercritical condition through Aspen Plus and ANN approaches. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00933-5.

Nguyen, T. D. B., Ngo, S. I., Lim, Y. I. L., Lee, J. W., Lee, U. D., & Song, B. H. (2012). Three-stage steady-state model for biomass gasification in a dual circulating fluidized-bed. Energy Conversion and Management, 54, 100–112.

Pantaleo, A. M., Camporeale, S., & Shah, N. (2014). Natural gas-biomass dual fuelled microturbines: Comparison of operating strategies in the Italian residential sector. Applied Thermal Engineering. https://doi.org/10.1016/j.applthermaleng.2013.10.056.

Puig-Arnavat, M., Bruno, J. C., & Coronas, A. (2010). Review and analysis of biomass gasification models. Renewable and Sustainable Energy Reviews, 14, 2841–2851.

Rostamzadeh, H., Ghiasirad, H., Amidpour, M., & Amidpour, Y. (2020). Performance enhancement of a conventional multi-effect desalination (MED) system by heat pump cycles. Desalination, 477, 114261.

Safieddin Ardebili, S.M., Asakereh, A., & Soleymani, M. (2020). An analysis of renewable electricity generation potential from municipal solid waste: a case study (Khuzestan Province, Iran). Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01011-6.

Shu, G., Shi, L., Tian, H., Deng, S., Li, X., & Chang, L. (2017). Configurations selection maps of CO2-based transcritical Rankine cycle (CTRC) for thermal energy management of engine waste heat. Applied Energy, 186, 423–435.

Soltani, S., Mahmoudi, S. M. S., Yari, M., & Rosen, M. A. (2013). Thermodynamic analyses of a biomass integrated fired combined cycle. Applied Thermal Engineering, 59(1–2), 60–68.

Wagner, H., Wulf, C., & Kaltschmitt, M. (2015). Polygeneration of SNG, heat and power based on biomass gasification and water electrolysis—concepts and their assessment. Biomass Conversion and Biorefinery, 5, 103–114.

Xiao, G., Jin, B. S., Zhong, Z. P., Chi, Y., Ni, M. J., Cen, K. F., et al. (2007). Experimental study on MSW gasification and melting technology. Journal of Environmental Science, 19(11), 1398–1403.

Zhang, X., Li, H., Liu, L., Zeng, R., & Zhang, G. (2016). Analysis of a feasible trigeneration system taking solar energy and biomass as co-feeds. Energy Conversion and Management. https://doi.org/10.1016/j.enconman.2016.05.063.

Zhao, L., Wang, H., Qing, S., & Liu, H. (2010). Characteristics of gaseous product from municipal solid waste gasification with hot blast furnace slag. Journal of Natural Gas Chemistry, 19(4), 403–408.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farajollahi, A., Hejazirad, S.A. & Rostami, M. Thermodynamic modeling of a power and hydrogen generation system driven by municipal solid waste gasification. Environ Dev Sustain 24, 5887–5916 (2022). https://doi.org/10.1007/s10668-021-01690-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-021-01690-9