Abstract

Cellulose activation is a necessary step in many industrial processes including production of cellulose derivatives, regenerated cellulose, biofuels and biochemicals. Expansins and expansin-related proteins have been shown to disrupt the fibrillar aggregation and loosen the structure of lignocellulosic materials but typically lack lytic activity. Therefore, they offer a new but rather unexploited possibility for biomass to obtain better accessibility and reactivity. From an applied perspective, expansin-related proteins have been investigated for their potential to promote enzymatic hydrolysis of cellulosic substrates for the purpose of producing biofuels. The aim of this review is to compare conventional and emerging technologies relevant to cellulose activation, and critically evaluate the potential of expansin-related proteins for this purpose. As part of this assessment, methods to evaluate the action of expansin-related proteins on cellulosic substrates are summarized, and reported impacts are discussed in relation to source of the cellulosic substrate and treatment conditions. An outlook on prospective applications of expansin-related proteins is presented.

Similar content being viewed by others

Introduction

Many pre-treatment methods have been developed for cellulosic materials (Meng and Ragauskas 2014; Aftab et al. 2019). These include chemical, physical, physicochemical, biochemical methods and combinations thereof (Fig. 1). The pre-treatments are necessary to increase uniformity of the material and modify the material properties to be more suitable for further processing towards the end applications. Activation treatments are aimed at increasing the accessibility and reactivity of the hydroxyl groups of cellulose prior to chemical modification, and thereby obtain reproducible end products while improving cellulose reactivity for pulp dissolution and minimizing reactant demand (Heinze et al. 2018). Activation requires careful optimization of process parameters because reactivity depends on the raw material origin (softwood and hardwood), its process history (kraft and sulfite) and the bleaching method used (Strunk et al. 2011; Palme et al. 2016; Ferreira et al. 2020). In addition, raw material properties such as degree of polymerization, crystallinity, dimensions of the crystallites and fibril aggregates as well as pore volume distribution are crucial (Duan et al. 2015; Heinze et al. 2018).

The activation treatment has different effects on the structure of lignocellulosic biomass (Meng and Ragauskas 2014; Aftab et al. 2019). In general, increase in surface area improves the reactivity, and many activation methods are based on increasing the porosity (internal surface) or decreasing the polymer size (external surface). An alternative technique to activate cellulosic materials is to disrupt the intermolecular interaction (strong hydrogen bonding) among fibers, which leads to less ordered fiber structures. Some treatment techniques are also capable of altering the crystalline structure of cellulose. Traditional activation methods strongly rely on chemicals, using acidic and/or alkaline treatments that are typically corrosive and may liberate degradation side products. With chemical pre-treatment, concentration of the swelling agent, reaction time, temperature and mixing all greatly affect the success of activation (Heinze et al. 2018). On the other hand, mechanical treatments typically have a high energy consumption. Since pre-treatments can be expensive, new improved methods are constantly being researched. Alternative biochemical methods are gaining interest because of their mild processing conditions under aqueous media and atmospheric pressure (Henriksson et al. 2005; Kumar 2021). However, enzyme costs and lack of suitable recovery methods are still a challenge for pre-treatment of lignocellulosic materials in biorefineries (Merino and Cherry 2007; Jørgensen and Pinelo 2017).

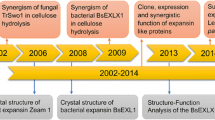

Given the potential of expansins to disrupt the fibrillar structure of cellulosic materials without apparent lytic activity (Cosgrove 2000), the activation of lignocellulosic materials using expansins and expansin-related proteins presents a new possibility for material development. Expansins were reported over 30 years ago and shown to trigger plant cell wall expansion (Cosgrove 1989) through disrupting noncovalent bonds at load-bearing junctions between cellulose microfibrils or cellulose microfibrils and matrix polysaccharides (McQueen-Mason and Cosgrove 1994; Cosgrove 2000, 2015). Expansin-related proteins have since been discovered in many bacteria and fungi (Georgelis et al. 2015; Cosgrove 2017).

Herein, we review conventional and emerging technologies for cellulose activation. As part of this review, key findings concerning the effects of expansin-related proteins on cellulosic materials is discussed. In particular, the conditions used for the cellulose processing and activation with expansin-related proteins are reviewed and compared with the conventionally used pre-treatment methods. The binding of expansin-related proteins to different lignocellulosic materials and characterization methods used to evaluate their activity on these materials are summarized. Finally, prospective opportunities to exploit expansin-related proteins for cellulose activation are briefly discussed.

Currently used chemical and mechanical treatments for cellulose activation

Alkali-treatments

The most common method for cellulose activation is treatment with aqueous alkali (Heinze et al. 2018; Fechter et al. 2020). Alkali pre-treatment is used for industrial scale preparation of cellulose ethers and regenerated cellulose (Fechter et al. 2020). Sodium hydroxide is used for this purpose since it is easily available, low-cost, and relatively efficient. In the preparation of textile fibers, for example, the pulp is pre-treated in a mercerization step using 17.5% NaOH at 45–55 °C for few hours (Fechter et al. 2020). The cellulose becomes highly swollen and goes through major morphological changes (Fig. 2) as the fibers shrink in length and their width increases leading to more circular structures (Ott et al. 1954; Heinze et al. 2018; You et al. 2021). In addition, the high alkali dissolves the residual hemicelluloses. A challenge with high alkali concentrations is that it may also induce uncontrolled oxidative degradation (Heinze et al 2018). Therefore, mercerization is carried out using inert gas atmosphere or using reducing agents such as NaBH4 (Heinze et al. 2018). The use of inert gas reaction vessels as well as the highly concentrated and corrosive alkali solutions are the main drawbacks of this activation treatment.

Cellulosic fibers go through morphological changes during alkaline mercerization step. The schematic transformation of the morphological changes of cellulose fibers (e.g., starting bean shaped), firstly due to swelling followed by longitudinal fibers shrinkage leads first to elliptic and then to circular structures. Purple (0.8), blue (1.0) and orange (1.3) color guidelines are shown to highlight the magnitude of dimensional changes of fiber. During the transformation cellulose I (parallel arrangement) changes to cellulose II (antiparallel arrangement) modified from Ott et al. 1954 and Okano and Sarko 1985

The activation treatment is mainly controlled by the concentration of alkali and temperature (Fechter et al. 2020). Diluted alkali solutions cause widening of the existing micropores, whereas increasing the alkali concentration up to 4–8% causes splitting of the fibrillar aggregates, thus further increasing the available surface area (Heinze et al. 2018). Concentrated alkali solutions containing e.g. 12–14% NaOH lead to increase in swelling and partial transformation of cellulose I (parallel arrangement) to cellulose II (antiparallel arrangement), even at room temperature (Okano and Sarko 1985; Budtova and Navard 2016).

Acidic treatments

Acidic pre-treatments cause hydrolysis of the hemicelluloses and reduction in the DP of the cellulosic material thus increasing the available surface area and improving the homogeneity and purity of the raw material (Palme et al. 2016). In addition, the acids may also cause swelling of cellulose which is slightly higher than in water (Ogiwara and Arai 1968; Heinze et al. 2018). Industrially, acidic treatments are used for the production of microcrystalline cellulose (Vanhatalo and Dahl 2014; Trache et al. 2020) and as a pre-treatment step for the production biofuels, either prior to enzymatic saccharification or for direct liberation of glucose from biomass (Balan et al. 2013). Most often, the acidic pre-treatments use mineral acids such as sulfuric acid, hydrochloric acid and nitric acid (Zhou et al. 2021). The pre-treatments can be carried out using concentrated acid or dilute acid. However, concentrated acid pre-treatments are less attractive because of issues related to equipment corrosion, acid recovery and formation of side products (Hu and Ragauskas 2012; Zhou et al. 2021). Dilute acid treatments require elevated temperature to proceed in reasonable timescales. Temperatures between 120 and 220 °C have been applied, at higher temperature for a short retention time or at lower temperature for longer retention time (30–90 min). The amount of acid has usually been 0.5–2% (Zhou et al. 2021).

It is characteristic to acidic treatments that the initial hydrolysis rate is rapid but as the reaction proceeds it slows down until it reaches the levelling-off degree of polymerization (LODP), after which hydrolysis rate is considerably slower or does not proceed. The LODP also depends on the raw materials properties and it has been observed that never-dried pulps have higher LODP than once-dried pulps for example (Palme et al. 2016). An explanation for this might be that the hornification which is induced by drying leads to coalescence of cellulose fibrils, which increases the stress in the cellulose. This stress may enhance acid hydrolysis reactivity (Palme et al. 2016). Xylan content is also known to affect the LODP which may also partly be ascribed to the lower degree of hornification found in xylan-rich pulps (Han et al. 2012; Palme et al. 2016).

Steam explosion

Steam explosion is a combination of thermal, chemical, and mechanical treatment. The biomass is heated with hot steam at temperatures of 160–260 °C and under elevated pressure of 1–5 MPa for a short period of time after which the pressure is suddenly released to atmospheric level (Wang et al. 2015a; Duque et al. 2016). This causes stress and shear forces, and together with the steam, leads to hydrolysis of the biomass. The parameters that affect the extent of activation are raw material particle size, temperature, moisture and residence time (Wang et al. 2015a; Duque et al. 2016). Usually, the residence time has been only from seconds to a few minutes. After the treatment the slurry can be filtered to separate the solids from the pre-hydrolysate. Steam explosion can be applied using water as the only catalyst and swelling agent; however, quite often the steam-explosion method is acid-catalyzed or alkali-catalyzed. The aim of these modifications is to improve the hemicellulose solubilization (acid-catalyzed) or remove lignin and hemicellulose and enhance the cellulose swelling properties (alkali-catalyzed). Currently, steam explosion is used as pre-treatment prior to enzymatic hydrolysis and fermentation in a demonstration plant for the production of bioethanol in Finland (Bioenergy 2023). In addition, steam explosion treatment has been studied semi-industrially as an alternative for chemical mechanical pulping (CMP) and chemical thermo mechanical pulping (CTMP) because explosion treated wood chips requires less refining energy and can generate pulps with higher paper strength properties than the ones prepared with conventional CMP and CTMP methods (Tomasec and Kokta 1991; Kokta and Ahmed 1993). Steam explosion has also been studied for the extraction of hemicelluloses and as pre-treatment for production of dissolving pulp (Kihlman et al. 2011; Jedvert et al. 2012; Martin-Sampedro et al. 2014; Martino et al. 2017).

Mechanical treatments

Mechanical treatments are traditionally used as a pre-treatment method given the simplicity of the machinery and relatively short treatment times. However, the main drawback is high energy consumption. Mechanical treatments are used in the production of high-quality papers, in semi-industrial textile fiber production and in the production of nano/microfibrillated celluloses (Missoum et al. 2013; Salmela et al. 2016; Bajpai 2018b; Vehviläinen et al. 2020). Several different devices have been developed for the grinding and refining, including conical and disk refiners, extruders, ball/rod mills, high shear mixers, homogenizers and fluidizers (Lumiainen 1998; Missoum et al. 2013). Mechanical treatments may induce fiber cutting and reduction of DP (Fig. 3a), partial removal of the fiber wall (external fibrillation), and formation of fines and internal fibrillation (weakening of the internal structure of the fiber cell wall) (Lumiainen 1998). Changes in the crystallinity, redistribution of hemicelluloses or leaching of colloidal material are also possible (Tian et al. 2014; Huang et al. 2019). In addition, changes in fiber structure such as curling (or straightening), or creation of kinks are common. In principle, mechanical treatments can be implemented using wet or dried material and depending on the type of treatment, the impact on the lignocellulosic material is different. In the presence of water, pH affects the refining process (Lumiainen 1998) where high pH makes fibers slippery, which hinders the contacts with the griding units. By contrast, too low pH reduces the swelling of the fibers and hinders opening of the fiber structure. Figure 3b shows the refining mechanism for commonly used rotor stator system. The energy is mainly transferred to the fibers during edge-to-surface and edge-to-edge contact phase (Lumiainen 1998). Surface to surface contact cause flattening of the fibers.

Modified from Lumiainen (1998)

a Changes in fiber structure during mechanical treatment/ refining. b Process of refining: fibers are first collected to the mechanical refiner and during the first contacts with the refiner the water squeezes out from the fiber bundle. Fiber refining occurs in edge-to-surface, edge-to-edge, and surface-to-surface contact phases.

Biochemical treatments for cellulose activation

Enzymatic treatments

Biochemical treatments using hydrolyzing enzymes have been shown to improve the reactivity of pulps (Henriksson et al. 2005; Ibarra et al. 2010; Gehmayr et al. 2011). Endoglucanases and xylanases have been used solely, in cocktails, and in combination with mechanical pre-treatments (Grönqvist et al. 2014; Miao et al. 2015; Kumar 2021). Endoglucanases cause hydrolysis of glycosidic bonds which reduces DP and viscosity and opens the fiber structure, leading to increased swelling and porosity (Miao et al. 2015). Xylanases are used to remove hemicelluloses and obtain higher cellulose purity. Compared to acidic pre-treatments, the enzymatic treatments have been observed to generate more porous fiber structures (Grönqvist et al. 2014). Traditionally, the enzymatic treatments have been carried out at relatively low substrate consistency, but recent studies have indicated that high substrate consistency can increase the productive adsorption of enzymes and is also beneficial from economical point of view (Wang et al. 2015b; Pere et al. 2020). The impact of hydrolytic enzymes depends on the enzyme family; for example, certain glycoside hydrolase family 45 (GH45) enzymes reportedly act solely on cellulose, causing reduction in DP and leading to a substrate with a high micropore volume (Rahikainen et al. 2019). By contrast, certain GH5 and GH7 hydrolases act on both cellulose and hemicelluloses (Rahikainen et al. 2019). In addition, the presence or absence of carbohydrate binding molecules (CBM) has been investigated (Ibarra et al. 2010; Várnai et al. 2013; Rahikainen et al. 2019). In general, CBMs appear to improve enzyme action at low substrate consistency but at high consistency their presence becomes negligible or even detrimental (Rahikainen et al. 2019).

Expansin-related proteins for lignocellulose processing and activation

Our current understanding relating to the biological role of expansins and expansin-related proteins, as well as structure–function correlations identified for this protein family, is expertly reviewed elsewhere (McQueen-Mason and Cosgrove 1995; Cosgrove 1999, 2000, 2015, 2017). Following a concise summary of their classification, the current review focuses on reported impacts of expansin-related proteins on cellulosic materials and functional attributes that align with prospective applications in lignocellulose processing.

Classification of expansin-related proteins

Expansins and expansin-like proteins are classified into five distinct subgroups, of which four are found in plants (EXPA, EXPB, EXLA and EXLB) and one (EXLX) is found in other eukaryotes (e.g., fungi, oomycetes) and bacteria (Kende et al. 2004; Quiroz-Castañeda et al. 2011; Lohoff et al. 2021). In plants, there are two major families: α-expansins (EXPA) which have been linked to acid-induced cell wall loosening, and β-expansins (EXPB) which are identified as subset of grass pollen allergens and facilitate pollen tube invasion (Cosgrove 2015). Plants also have two smaller families, expansin-like A (EXLA) and expansin-like B (EXLB); however, their biological functions are not fully understood (Cosgrove 2015). Microbial expansin-like (EXLX) proteins are often identified in plant pathogens or saprotrophs growing on plant litter and have been implicated in plant colonization (reviewed elsewhere (Cosgrove 2017)).

Plant expansins and microbial expansin-like proteins (Fig. 4) comprise an N-terminal “D1” domain structurally homologous to family GH45 glycoside hydrolases and a C-terminal domain “D2” that has been assigned to a Type-A CBM family 63 (Boraston et al. 2004; Kerff et al. 2008; Cosgrove 2015). Microbial expansin-related proteins that lack the C-terminal CBM include loosenins and ceratoplatanins (Quiroz-Castañeda et al. 2011; Baccelli 2015; Monschein et al. 2023), sometimes also referred as EXPN, whereas those that include domains besides D1 and D2 include swollenins. For example, SWO1 is one of the most extensively studied fungal swollenins and includes an N-terminal fibronectin III and CBM1 domain (Saloheimo et al. 2002). Moreover, certain bacterial expansin-related proteins comprise a glycoside hydrolase domain (e.g., GH5) (Georgelis et al. 2014). As such, the molecular weight of expansin-related proteins ranges from approximately 12–75 kDa (Cosgrove 2001; Saloheimo et al. 2002; Jäger et al. 2011; Georgelis et al. 2011; Kim et al. 2013a).

Functional characterization of expansin-related proteins on cellulosic materials

Measuring the activity of expansins and expansin-related proteins is rather difficult because they do not cause covalent modifications on substrates that could be easily detected. In addition, as mainly non-lytic proteins, they do not release readily detectable products. The exceptions to date are certain swollenins, where SWO1 displays very low levels of hydrolytic activity towards β-glucan and certain cello-oligosaccharides (Andberg et al. 2015; Eibinger et al. 2016), AfSwo1 from Aspergillus fumigatus displays low hydrolytic activity towards carboxymethyl cellulose (CMC) (Chen et al. 2010), and SWO2 from T. pseudokoningii displays low hydrolytic activity towards CMC and regenerated amorphous cellulose (Zhou et al. 2011). A challenge is also faced in finding a characterization method that could simultaneously detect the protein-induced changes from microfibril scale (nm) up to fiber scale (mm) (Gourlay et al. 2012; Eibinger et al. 2016).

Cosgrove and his team established complementary methods to measure the impact of plant expansins and expansin-related proteins on plant cell walls as well as filter paper (Cosgrove 2017). Methods developed to study expansin action on cellulosic materials were previously summarized in (Gourlay et al. 2012) and an updated summary is provided in Table 1.

Binding to lignocellulose components

Binding of microbial expansin-related proteins to cellulose have mainly included filter paper, microcrystalline cellulose (e.g., Avicel), phosphoric acid swollen cellulose, cotton fiber, and bacterial microcrystalline cellulose. Typical temperatures and pH values for the binding studies range from 4 °C to 25 °C and pH 5.0–pH 7.5, respectively (Table 2). The main factors affecting the binding of proteins are ionic and hydrophobic interactions (Cosgrove et al. 2017).

Adsorption isotherms have been collected for some expansin-related proteins and different lignocellulosic substrates (Table 2). The different binding conditions make it difficult to compare binding capacities of proteins reported in different publications; however, in nearly all cases where lignocellulosic substrates besides cellulose were included in the same binding study, binding by the expansin-related protein to crystalline cellulose (Avicel) was comparatively low. It has been speculated that the high crystallinity of Avicel hinders the adsorption as compared to hemicelluloses which are generally more amorphous (Bunterngsook et al. 2015). Chemical treatments such as phosphoric acid swelling has been shown to increase the binding of bacterial expansins on cellulosic substrates (Kim et al. 2013b; Bunterngsook et al. 2015). Other binding studies have included xylan from birch wood (Yennawar et al. 2006; Lee et al. 2010; Tovar-Herrera et al. 2015; Eibinger et al. 2016) oat spelt, larch wood (Lee et al. 2013; Kim et al. 2013b) and arabinoxylan (Georgelis et al. 2011), as well as pectin (Olarte-Lozano et al. 2014). The pH dependency of the protein binding to xylans and pectin points to the electrostatic nature of that interaction. The net charge of the proteins depends on its isoelectric point (pI): at pH values below pI the net charge is positive whereas above it is negative. For example, Olarte-Lozano et al. (2014) compared the binding behavior of BsEXLX1 and PcExl, which have isoelectric points of 9.0 and of 4.8, respectively. Whereas acidic and near neutral conditions promoted BsEXLX1 binding to pectin and glucuronoxylan (anionic substrates), binding by PcExl1 to these substrates was hindered.

The presence of different additives, such as surfactants has also been studied. Polyoxyethylene sorbitol had no effect on the binding of BsEXLX1 on Avicel (Kim et al. 2013b). Duan et al. (2018) showed that the BsEXLX1 adsorption onto cellulose film was dependent on surfactant concentration; at low concentrations (0.02 mM Polyoxyethylene sorbitol or polyethylene glycol) adsorption was enhanced whereas at higher surfactant concentrations (0.4 mM) the adsorption was hindered. Other additives, such as 1 M urea and 0.5% sodium dodecyl sulfate had either no or small impacts on the adsorption of LeEXP2 (Liu et al. 2014). Consistent with non-ionic interactions driving the binding to cellulose, addition of up to 1 M NaCl increased BsEXLX1 binding to Avicel (Kim et al. 2013b). Although no metal binding sites that could stabilize the D2 domain were predicted for BsEXLX1 (Yennawar et al. 2006), binding to Avicel was enhanced in the presence of up to 5 mM Zn2+(Kim et al. 2013b).

Impact on cellulose fiber arrangement

Impacts of expansin-related proteins on cellulose fiber morphology were first seen by light microscopy where mercerized cotton fiber appeared to form swollen areas after sonication and treatment with yeast culture supernatant containing SWO1 (Saloheimo et al. 2002). Similarly, treatment of mercerized cotton fiber with the loosenin LOOS1 from Bjerkandera adusta induced bubble formation after sonicating the fiber, where bubble formation could be correlated to LOOS1 loading (Quiroz-Castañeda et al. 2011). On the other hand, when visualized by scanning electron microscopy (SEM), SWO1 did not appear to induce swelling of filter paper (Jäger et al. 2011) and instead increased the surface smoothness of mercerized cotton fiber (Gourlay et al. 2012). Moreover, atomic force microscopy revealed no change in surface roughness of either amorphous or crystalline cellulose preparations after treatment with SWO1 (Eibinger et al. 2016). Light microscopy images of Avicel treated with the AfSWO swollenin from Aspergillus fumigatus revealed reduced cellulose aggregation and thus smaller cellulose particle size, without the concomitant increase in reducing end formation (Chen et al. 2010). Similarly, the recombinant SWO1 reportedly reduced the particle size of filter paper cellulose by weakening the fiber network (Jäger et al. 2011), which was also observed by SEM of cellulose filter paper treated with BsEXLX1 (Kim et al. 2009). Nevertheless, it is evident that the impact of swollenins on the fiber structure vary considerably depending on the type and composition of the fibers and the conditions under which the swollenins are applied.

Impacts of expansin-related proteins on cellulose fiber crystallinity vary. The recombinantly produced SWO1 reportedly reduced the crystallinity of multiple cellulose preparations (e.g., filter paper, Avicel, alpha cellulose) by 10–20% as measured by x-ray diffraction (XRD) (Jäger et al. 2011). Similarly, BsEXLX1 reduced the crystallinity index (CrI) of Avicel by approximately 20%, which was correlated to a 6% increase in surface area as measured by nitrogen adsorption (Duan et al. 2018). A change in crystallinity was not observed, however, using wide-angle x-ray scattering (WAXS) to compare Avicel samples before and after treatment with SWO1 (Eibinger et al. 2016) or SWO2 from Trichoderma pseudokoningii S38 (Zhou et al. 2011). The methodological dependency and variation of cellulose crystallinity index values (Park et al. 2010) and the complex nature of cellulose composition means that the available data should be compared as qualitative relative measurements rather than absolute values (Lee et al. 2016).

In an effort to overcome some of the challenges in measuring cellulose crystallinity that could contribute to the varying results, and to be able to quantify the possible changes in accessibility, Gourlay et al. (2012) developed a method whereby the adsorption of carbohydrate binding molecules (CBM) that preferentially bind amorphous cellulose (i.e., from family CBM44) and crystalline cellulose (i.e., from family CBM2) was tested after treating mercerized cotton with SWO1. These analyses showed increased CBM44 and CBM2a binding to mercerized cotton after SWO1 treatment, with greater impacts on CBM2a binding that increased by nearly 50% (Gourlay et al. 2012). FTIR and NMR have also been used to study the impacts of expansin-related proteins on fiber rearrangement and Cms and BsEXLX1 proteins have been observed to reduce hydrogen bonding of cotton and Avicel respectively (Haque et al. 2015; Duan et al. 2018).

Impact on the mechanical properties of cellulosic materials

Early reports of plant expansins demonstrate their potential to weaken cellulosic filter paper by disrupting the hydrogen bonding between cellulose fibers (McQueen-Mason and Cosgrove 1994). The potential of microbial expansin-related proteins to weaken filter paper networks has since been shown for both fungal and bacterial proteins. For example, Saloheimo et al. (2002) observed that treating filter paper with SWO1 decreased its loading capacity by 15–20%, whereas others (Kim et al. 2009) observed a 29% reduction in the tensile strength of filter paper strips after treatment with BsEXLX1. Filter paper weakening activity has also been observed for the bacterial expansin-like proteins HcEXLX2 (Lee et al. 2010) and PcExl1 (Olarte-Lozano et al. 2014) as well as fungal loosenins from Phanerochaete carnosa (PcaLOOLs) (Monschein et al. 2023), which comprise only the D1 domain of expansin-related proteins. Notably, fusion of a D2 domain to the PcaLOOLs enhanced protein binding to cellulosic substrates but did not alter the tensile properties measured by filter paper weakening (Monschein et al. 2023). When comparing to chemical treatments, urea solution has led to 40–50% reduction in mechanical properties of filter papers (Kim et al. 2009; Saloheimo et al. 2002). Besides filter paper weakening, rheometry was performed to quantify the impact of PcaLOOLs on the strength of cellulose nanofiber networks (Monschein et al. 2023). Those studies revealed a protein dose dependent decrease in the yield strain of CNF, which was also dependent on the PcaLOOL applied and pH of the CNF treatment. Together, filter paper weakening measurements and rheometry offer complementary approaches to quantify the impact of expansin-related proteins on different cellulose preparations.

Impact on the biochemical processing of cellulosic materials

The potential of expansin-related proteins to boost the enzymatic saccharification of lignocellulose substrates provides an in-direct measure of expansin impacts on accessibility to cellulose fiber networks. Enhancement of cellulase and hemicellulase activity by expansin-related protein has been reviewed by Kim et al. (2014) and Liu et al. (2015). The measured impacts of expansin-related proteins on enzyme performance depends on several factors, including the substrate used, reaction time, expansin dose, the enzyme dose as well as the enzyme system used (Baker et al. 2000). For example, BsEXLX1 and HcEXLX2 have been observed to enhance the production of soluble sugars from cellulose filter paper at low cellulase loadings (e.g., 0.06 FPU/ g cellulose), but at higher cellulase loadings the measured synergy is greatly reduced (Kim et al. 2009; Lee et al. 2010). It has been discussed that the reason for this is likely that expansin-like proteins and cellulases are competing for the same binding site. In some cases, like SWO2 and ScExlx1, pre-treatment of the cellulose substrate with the expansin-related protein, followed by treatment with cellulase, was needed to boost cellulase performance (Tovar-Herrera et al. 2015; Zhou et al. 2011). A challenge is that at times a synergistic effect is also observed with proteins that are generally considered “inert” such as BSA (Lee et al. 2010; Olarte-Lozano et al. 2014; Bunterngsook et al. 2015). This has been attributed to reduced unspecific binding of hydrolyzing enzymes to the substrate when BSA is present. When summarizing impacts of substrate on the potential of expansin-related proteins to boost cellulase performance, Liu et al. (2015) note the advantages of substrates with comparatively high hemicellulose and low lignin contents.

Impact of operational conditions on the performance of expansin-related proteins

The mild processing conditions of protein treatments (pH 5–7), compared to conventional thermo-chemical treatments, may bring savings as regards to energy consumption. Moreover, the near neutral pH values will presumably cause less corrosion to equipment than chemical aided swelling treatments. Short treatment times to achieve beneficial substrate properties, however, are necessary for efficient and continuous processes.

Plant expansins are expected to favor slightly acidic conditions because their function is linked to the acid-induced growth of plant cell walls (Cosgrove 1989), where plant cell wall extension is generally highest at pH < 4 and gradually diminishes when approaching pH 7 (Cosgrove 1999). The pH optimum for plant expansins does vary, however, as exemplified by Zea m 1 (EXPB1), which displays a pH optimum between pH 5 and 6 (Li et al. 2003). So far, most reports of microbial expansin-related proteins measure highest binding to cellulosic substrates within the acidic pH range and perform activity measurements between pH 4.5 and 6.0. Notably, in the case of microbial expansin-related proteins, the choice of pH is often time determined by the pH optimum of cellulolytic enzymes used in synergism assays.

As regards to temperature stability, the wall extension activity of Zea m1 (EXPB1) was the greatest at 30 °C and significantly dropped at 50 °C; the activity was lost at 60 °C (Li et al. 2003). By contrast, the plant expansin LeEXP2 retained 100% activity after 48 h at 50 °C, as measured by its ability to boost cellulase performance (Liu et al. 2014). Studies of microbial expansin-related proteins to date report similar temperature stability profiles. For example, LOOS1 retained activity up to 8 h at 40 °C (Quiroz-Castañeda et al. 2011), and BsEXLX1 and TrSWO recombinantly produced in Pichia pastoris retained more than 70% activity after 12 h at 70 °C, and ~ 80% activity after 24 h at 50 °C (Wang et al. 2014). On the other hand, when recombinantly produced in Escherichia coli, BsEXLX1 denatures after 30 min at temperatures over 50 °C, pointing to contributing factors from the production host, such as glycosylation, on the thermostability of BsEXLX1(Kim et al. 2013b).

Already after 15–60 min, several expansin-related proteins can weaken the mechanical strength of filter papers and other cellulose networks (Kim et al. 2009; Lee et al. 2010; Monschein et al. 2023; Olarte-Lozano et al. 2014; Saloheimo et al. 2002). Compared to studies that measure the strength of cellulose networks, impacts of expansin-related proteins on the enzymatic saccharification are often observed after several hours of incubation; however, as discussed above, such studies strongly depend on both the substrate and enzyme composition.

Besides operation temperature, pH and treatment time, substrate consistency and protein loading required to achieve desired substrate properties is critical to application cost. In general, the amount of expansin-related protein used per amount of cellulose substrate is lower when aiming to boost cellulolytic activity as compared to disrupting cellulose fiber networks as observed by microscopy and rheometry (Table 3). Moreover, tested substrate consistencies are typically less than 5% w/v (Table 3). It is anticipated that protein loading can be decreased, and substrate consistency increased, with improved mixing and by integrating the expansin treatment with mechanical treatment of cellulosic substrates.

Prospective applications of expansin-related proteins in cellulosic materials

So far, applications of expansin-related proteins have largely focused on their potential to enhance the enzymatic saccharification of cellulosic substrates for the production of fuels and commodity chemicals. As summarized above (Table 3) and reviewed in (Liu et al. 2015), the potential of expansin-related proteins to boost the enzymatic deconstruction of cellulose depends on the enzyme system, enzyme loading, and substrate composition, pointing to a need for tailor-made applications of expansins used for this purpose. By comparison, the potential application of expansin-related proteins in the preparation of value-added cellulosic pulps has been underexplored. Given their non-lytic mode of action, expansin-related proteins offer particular advantages for materials applications. An outlook of future application areas is summarized below.

Biofuels

Enzymatic saccharification of lignocellulosic materials into monosaccharides and fermentation into bioethanol is hindered by their low accessibility and heterogeneous composition (Arantes and Saddler 2010). It is still a challenge to obtain sufficient conversion degrees of lignocellulosic biomass into monosaccharides and with a reasonable timescale. For industrially and economically reasonable process, the cellulose conversion should reach 80–90% (Senthilkumar and Gunasekaran 2005). Enzymatic hydrolysis requires mixtures of different enzymes in large quantities which reduces the cost-effectiveness of the process (Arantes and Saddler 2010). It has been estimated that 40- to 100-fold more enzyme(s) is required to produce an equivalent amount of ethanol from lignocellulose than from starch (Merino and Cherry 2007). Several pilot and semi-industrial processes based on enzymatic saccharification have been launched for the production of bioethanol in EU and in US (Balan et al. 2013; Bušić et al. 2018; Bioenergy 2023) but many of them have faced challenges related to the cost-effectiveness and runnability issues (Østby et al. 2020). One possibility suggested to overcome this issue is an addition of small amount proteins that enhance the activity of enzymes, thus reducing the total enzyme loading and cost. The capability of expansins and expansin-related proteins to enhance enzymatic hydrolysis has been intensively studied and a synergistic effect has been observed with both cellulases and hemicellulases (Lee et al. 2013). The hydrolytic activity of enzymes has often increased 1.2–fivefold (Jäger et al. 2011; Lin et al. 2013; Wang et al. 2014) with simultaneous use of expansins and hydrolytic enzymes. However, industrial scale utilization of expansin-related proteins is not existing due to lack of production and expression of expansins in various hosts at high expression levels and in finding a cost-effective purification and separation systems (Kim et al. 2014). The mixing ratio of the protein and enzymes still need optimization in achieving low loadings of synergistic protein with high synergistic activity and it is still not clear whether the treatment should be carried out sequentially or simultaneously. Furthermore, the performance and robustness of the expansins, especially related to thermostability should be clarified (Kim et al. 2014).

Textiles

The textile industry offers multiple possibilities for the utilization of enzymes and non-hydrolyzing proteins. Hydrolyzing enzymes, such as amylases, peroxidases, catalases and cellulases are used in different process stages including desizing, scouring, bleaching, dyeing, and finishing treatments of fabrics (Mojsov 2011; Kumar et al. 2021), Fig. 5. The aim of the scouring treatment is to remove the impurities such as fats, waxes, pectins and proteins from raw cotton (Mojsov 2011; Colombi et al. 2021). These substances are hydrophobic and cause negative impact on wettability and textile dyeing. Traditionally, the impurities have been removed by using hot aqueous sodium hydroxide, but nowadays also biochemical treatments using cocktails of pectinases and cellulases are used (Mojsov 2011; Colombi et al. 2021). It is conceivable that expansins and expansin-related proteins could enhance the removal of the impurities by swelling and opening the cotton structure and reducing the quantity of hydrolytic enzymes required for the scouring. On the other hand, sizing agents, such as starches and carboxymethyl celluloses are used to increase the strength and reduce the hairiness of the yarn before weaving. However, after the yarn has been weaved, the sizing agents are removed to improve the wettability and uniformity of the material. Desizing processes involve chemical or enzymatic treatments, which could be accelerated using expansins and expansin-related proteins. Likewise, bio-polishing treatments that improve the visual attractiveness of fabrics use cellulases to hydrolyze the microfibrils that protrude from the surface and to produce a smoother and glossy fabric surface. Denim washing or “bio-stonewashing” uses cellulases to loosen the indigo dye on the denim to give a special look, which could be assisted using expansin-related proteins. Alternatively, expansins could benefit fiber dyeing by facilitating the penetration of the dye chemicals to the matrix, thus reducing their consumption. Beyond enhancing enzymes already used in textile manufacturing, an attractive opportunity is to develop expansin-related proteins for the fiber production part (Fig. 5), for instance by enhancing the swelling and dissolution of cellulosic fiber prior to spinning. In this case, preferred expansin-related proteins would assist in controlling the degree of polymerization of cellulose fiber, increase cellulose purity (e.g., by helping to remove hemicelluloses) or reduce the consumption of dissolving chemicals.

Chemical modification

Chemical modification of cellulosic materials is one of the main tools in broadening its utilization into new applications (Ge et al. 2022). Especially cellulose esters are nowadays having a renaissance because alternatives for fossil-based plastics are of great interest (Endres 2019; Romão et al. 2022). Cellulose esters have high toughness, hardness, transparency, and clarity, and they can be produced with good color range. During the chemical modification, however, the rigid structure and insufficient accessibility of cellulose can lead to varying degrees of substitution and unpredictable properties (Kostag et al. 2019). At the same time, cellulose esters have poor moisture barrier properties and limited dimensional stability; moreover, many cellulose esters decompose below their softening temperature and therefore plasticizers are needed to bring the processing temperature below the polymer decomposition temperature (Molenveld and Slaghek 2022). To address these challenges, a possible role of expansin-related proteins would be to increase cellulose fiber accessibility and facilitate the penetration of the necessary chemicals and plasticizers thus improving product reproducibility and increase production yield.

Nanocellulose preparation

Nanocelluloses i.e., nanofibrillated celluloses are prepared by mechanically delaminating fibers into smaller dimensions using microfluidizers, homogenizers and grinders (Lavoine et al. 2012; Missoum et al. 2013). However, the compact structure of lignocellulose hinders its fibrillation into nanocellulose which leads to huge energy consumption during the mechanical fibrillation step. Many different pre-treatment methods have been developed to overcome this issue. Fibrillation is facilitated by increasing the charge of the pulp and introducing repulsive effects that lead to increased swelling (Lavoine et al. 2012; Missoum et al. 2013). The addition of charged groups is achieved through chemical modification such as carboxymethylation or quaternization, which requires organic solvent (e.g. ethanol or isopropanol) and oxidizing chemicals some of which can be harmful (e.g., sodium metaperiodate or sodium chlorite) or else expensive (e.g., TEMPO-radical) (Lavoine et al. 2012; Missoum et al. 2013). Enzymatic pre-treatments have also been used in combination with mechanical treatments (Henriksson et al. 2007; Pääkkö et al. 2007; Tong et al. 2022) to reduce energy consumption and are often seen as more environmentally friendly. Expansin-related proteins could possibly be used as pre-treatment or in combination with enzymatic hydrolysis to disrupt fiber aggregation and loosen the fiber structure, thus enhancing the fibrillation.

Delignification and bleaching of pulps for paper and packaging

Bleaching is one of the most important steps in the pulp and paper industry (Bajpai 2018a). Its aim is to remove residual lignin and resins to increase the brightness and improve cleanliness. Typically, the bleaching is carried out with aid of oxidizing agents, such as chlorine dioxide, oxygen, hydrogen peroxide or ozone in total chlorine free or elemental chlorine free processes. The challenge is that bleaching processes use hazardous chemicals, produces problematic effluents and are expensive (Bajpai et al. 2006). This has led to intensive research in finding more environmentally friendly methods for bleaching. Enzyme-aided bleaching using xylanases has been observed to enhance the bleaching process by reducing the consumption of chemicals by 20–25% (Viikari et al. 1994; Bajpai et al. 2006), however it cannot be used to fully replace the chemical bleaching because xylanases do not hydrolyze the lignin itself but the xylan network where part of the lignin-based compounds are trapped (Bajpai et al. 2006). Xylanase treatments have been developed as pre-bleaching or bleach boosting processes. Lignin-oxidizing enzymes, such lignin peroxidases, manganese peroxidases and oxidoreductases such as laccases have been intensively studied as alternative biochemical methods to replace hazardous bleaching chemicals (Kareem 2020). Lignin oxidizing enzymes have an advantage of minimizing damage to cellulose fibers (e.g., reduced viscosity, strength properties, yield); accordingly, a worthwhile study would be to explore the potential of expansin-related proteins to boost the performance of lignin oxidizing enzymes.

Conclusions

Plant expansins and microbial expansin-related proteins display promising characteristics relevant to the activation of cellulosic materials. These proteins have been shown to weaken cellulose fiber networks, creating a loosening effect that is similar to chemical urea treatment for example. Certain expansin-related proteins also boost cellulose hydrolyzing enzymes. Whereas the impact of expansin-related proteins on enzyme action has largely been studied for the purpose of biofuel production, less explored opportunities include enhancing enzyme systems used in the production of textiles and nanocelluloses. Some application areas may benefit from the non-lytic action of expansin-related proteins and their function in aqueous media at mild temperature and pH conditions, and under atmospheric pressure. Other application areas which require the control of molecular weight distribution and degree of polymerization may benefit from the synergistic effect of expansin-related proteins in combination with other pre-treatment methods or chemicals. The current challenges are to transform the current lab scale understanding of expansin-related proteins into real application scale, and demonstrate a clear, technology-based, feasible application potential. Overcoming existing challenges and identifying the best suited expansin-related proteins for cellulose materials manufacturing should motivate future scale-up and generate industrial pull towards demonstration efforts.

Data availability

Not applicable.

References

Aftab MN, Iqbal I, Riaz F, Karadag A, Tabatabaei M (2019) Different pretreatment methods of lignocellulosic biomass for use in biofuel production. Biomass Bioenergy Recent Trends Future Chall 1–24

Andberg M, Penttilä M, Saloheimo M (2015) Swollenin from Trichoderma reesei exhibits hydrolytic activity against cellulosic substrates with features of both endoglucanases and cellobiohydrolases. Biores Technol 181:105–113

Arantes V, Saddler JN (2010) Access to cellulose limits the efficiency of enzymatic hydrolysis: the role of amorphogenesis. Biotechnol Biofuels 3(1):1–11

Baccelli I (2015) Cerato-platanin family proteins: one function for multiple biological roles? Front Plant Sci 5:769

Bajpai P, Anand A, Sharma N, Mishra SP, Bajpai PK, Lachenal D (2006) Enzymes improve ECF bleaching of pulp. BioResources 1(1):34–44

Bajpai P (2018a) Brief description of the pulp and papermaking process. Biotechnology for pulp and paper processing 9–26

Bajpai P (2018b) Refining and pulp characterization. Biermann’s Handbook of Pulp and Paper 1–34

Baker JO, King MR, Adney WS et al. (2000) Investigation of the cell-wall loosening protein expansin as a possible additive in the enzymatic saccharification of lignocellulosic biomass. Appl Biochem Biotechnol 84:217–223. https://doi.org/10.1385/ABAB:84-86:1-9:217

Balan V, Chiaramonti D, Kumar S (2013) Review of US and EU initiatives toward development, demonstration, and commercialization of lignocellulosic biofuels. Biofuels, Bioprod Biorefin 7(6):732–759

Bioenergy ETIP (2023) Flagship (first-of-a-kind commercial) and demonstration cellulosic ethanol facilities, European technology and innovation platform. https://www.etipbioenergy.eu/value-chains/conversion-technologies/advanced-technologies/sugar-to-alcohols/flagship-first-of-a-kind-commercial-and-demonstration-cellulosic-ethanol-facilities?highlight=WyJlbnp5bWVzIl0=. Accessed 05 August 2023.

Boraston AB, Bolam DN, Gilbert HJ, Davies GJ (2004) Carbohydrate-binding modules: fine-tuning polysaccharide recognition. Biochem J 382(3):769–781

Budtova T, Navard P (2016) Cellulose in NaOH–water based solvents: a review. Cellulose 23(1):5–55

Bunterngsook B, Eurwilaichitr L, Thamchaipenet A, Champreda V (2015) Binding characteristics and synergistic effects of bacterial expansins on cellulosic and hemicellulosic substrates. Biores Technol 176:129–135

Bušić A, Marđetko N, Kundas S, Morzak G, Belskaya H, Ivančić Šantek M, Komes D, Novak S, Šantek B (2018) Bioethanol production from renewable raw materials and its separation and purification: a review. Food Technol Biotechnol 56(3):289–311

Chen X-a, Ishida N, Todaka N, Nakamura R, Maruyama J-i, Takahashi H, Kitamoto K (2010) Promotion of efficient saccharification of crystalline cellulose by Aspergillus fumigatus Swo1. Appl Environ Microbiol 76(8):2556–2561

Colombi BL, Valle RDCSC, Valle JAB, Andreaus J (2021) Advances in sustainable enzymatic scouring of cotton textiles: evaluation of different post-treatments to improve fabric wettability. Clean Eng Technol 4:100160

Cosgrove DJ (1989) Characterization of long-term extension of isolated cell walls from growing cucumber hypocotyls. Planta 177:121–130

Cosgrove DJ (1999) Enzymes and other agents that enhance cell wall extensibility. Annu Rev Plant Biol 50(1):391–417

Cosgrove DJ (2000) Loosening of plant cell walls by expansins. Nature 407(6802):321–326

Cosgrove DJ (2001) Enhancement of accessibility of cellulose by expansins. US Patent 6:326

Cosgrove DJ (2015) Plant expansins: diversity and interactions with plant cell walls. Curr Opin Plant Biol 25:162–172

Cosgrove DJ (2017) Microbial expansins. Annu Rev Microbiol 71:479–497

Cosgrove DJ, Hepler NK, Wagner ER, Durachko DM (2017) Measuring the biomechanical loosening action of bacterial expansins on paper and plant cell walls. Protein Carbohydr Interact Methods Protoc 157–165

Duan C, Li J, Ma X, Chen C, Liu Y, Stavik J, Ni Y (2015) Comparison of acid sulfite (AS)-and prehydrolysis kraft (PHK)-based dissolving pulps. Cellulose 22:4017–4026

Duan Y, Ma Y, Zhao X, Huang R, Su R, Qi W, He Z (2018) Real-time adsorption and action of expansin on cellulose. Biotechnol Biofuels 11(1):1–13

Duque A, Manzanares P, Ballesteros I, Ballesteros M (2016) Steam explosion as lignocellulosic biomass pretreatment. In: Mussatto S (ed) Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. Elsevier, Amsterdam, pp 349–368

Eibinger M, Sigl K, Sattelkow J, Ganner T, Ramoni J, Seiboth B, Plank H, Nidetzky B (2016) Functional characterization of the native swollenin from trichoderma reesei: study of its possible role as C1 factor of enzymatic lignocellulose conversion. Biotechnol Biofuels 9(1):1–19

Endres H-J (2019) Bioplastics. In: Wagemann K, Tippkötter N (eds) Biorefineries. Springer Cham, Switzerland, pp 427–468

Fechter C, Brelid H, Fischer S (2020) Possibilities for optimization of Industrial alkaline steeping of wood-based cellulose fibers. Molecules 25(24):5834

Ferreira JC, Evtuguin DV, Prates A (2020) Effect of cellulose structure on reactivity of eucalyptus acid sulphite dissolving pulp. Cellulose 27(8):4763–4772

Ge W, Shuai J, Wang Y, Zhou Y, Wang X (2022) Progress on chemical modification of cellulose in “green” solvents. Polym Chem 13(3):359–372

Gehmayr V, Schild G, Sixta H (2011) A precise study on the feasibility of enzyme treatments of a kraft pulp for viscose application. Cellulose 18:479–491

Georgelis N, Tabuchi A, Nikolaidis N, Cosgrove DJ (2011) Structure-function analysis of the bacterial expansin EXLX1. J Biol Chem 286(19):16814–16823

Georgelis N, Nikolaidis N, Cosgrove DJ (2014) Biochemical analysis of expansin-like proteins from microbes. Carbohyd Polym 100:17–23

Georgelis N, Nikolaidis N, Cosgrove DJ (2015) Bacterial expansins and related proteins from the world of microbes. Appl Microbiol Biotechnol 99:3807–3823

Gourlay K, Arantes V, Saddler JN (2012) Use of substructure-specific carbohydrate binding modules to track changes in cellulose accessibility and surface morphology during the amorphogenesis step of enzymatic hydrolysis. Biotechnol Biofuels 5:1–14

Gourlay K, Hu J, Arantes V, Andberg M, Saloheimo M, Penttilä M, Saddler J (2013) Swollenin aids in the amorphogenesis step during the enzymatic hydrolysis of pretreated biomass. Biores Technol 142:498–503

Gourlay K, Hu J, Arantes V, Penttilä M, Saddler JN (2015) The use of carbohydrate binding modules (CBMs) to monitor changes in fragmentation and cellulose fiber surface morphology during cellulase-and swollenin-induced deconstruction of lignocellulosic substrates. J Biol Chem 290(5):2938–2945

Grönqvist S, Hakala T, Kamppuri T, Vehviläinen M, Hänninen T, Liitiä T, Maloney T, Suurnäkki A (2014) Fibre porosity development of dissolving pulp during mechanical and enzymatic processing. Cellulose 21:3667–3676

Han W, Zhao C, Elder T, Chen K, Yang R, Kim D, Pu Y, Hsieh J, Ragauskas AJ (2012) Study on the modification of bleached eucalyptus kraft pulp using birch xylan. Carbohyd Polym 88(2):719–725

Haque MA, Cho KM, Barman DN, Kim MK, Yun HD (2015) A potential cellulose microfibril swelling enzyme isolated from bacillus sp. AY8 enhances cellulose hydrolysis. Process Biochem 50(5):807–815

Heinze T, El Seoud OA, Koschella A, Heinze T, El Seoud OA, Koschella A (2018) Cellulose activation and dissolution. Cellul Deriv Synth Struct Prop 173–257

Henriksson G, Christiernin M, Agnemo R (2005) Monocomponent endoglucanase treatment increases the reactivity of softwood sulphite dissolving pulp. J Ind Microbiol Biotechnol 32(5):211–214

Henriksson M, Henriksson G, Berglund L, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polymer J 43(8):3434–3441

Hu F, Ragauskas A (2012) Pretreatment and lignocellulosic chemistry. Bioenergy Res 5:1043–1066

Huang L, Wu Q, Wang Q, Wolcott M (2019) Mechanical activation and characterization of micronized cellulose particles from pulp fiber. Ind Crops Prod 141:111750

Ibarra D, Köpcke V, Ek M (2010) Behavior of different monocomponent endoglucanases on the accessibility and reactivity of dissolving-grade pulps for viscose process. Enzyme Microb Technol 47(7):355–362

Jäger G, Girfoglio M, Dollo F, Rinaldi R, Bongard H, Commandeur U, Fischer R, Spiess AC, Büchs J (2011) How recombinant swollenin from Kluyveromyces lactis affects cellulosicsubstrates and accelerates their hydrolysis. Biotechnol Biofuels 4:1–16

Jedvert K, Saltberg A, Lindström ME, Theliander H (2012) Mild steam explosion and chemical pre-treatment of Norway spruce. BioResources 7(2):2051–2074

Jørgensen H, Pinelo M (2017) Enzyme recycling in lignocellulosic biorefineries. Biofuels Bioprod Biorefin 11(1):150–167

Kang K, Wang S, Lai G, Liu G, Xing M (2013) Characterization of a novel swollenin from penicillium oxalicum in facilitating enzymatic saccharification of cellulose. BMC Biotechnol 13:1–9

Kareem HM (2020) Oxidoreductases: Significance for humans and microorganism. In: Mansour M-A (ed) Oxidoreductase. IntechOpen, Croatia, pp 123–130

Kende H, Bradford K, Brummell DA, Cho H-T, Cosgrove DJ, Fleming AJ, Gehring C, Lee Y, McQueen-Mason S, Rose JK (2004) Nomenclature for members of the expansin superfamily of genes and proteins. Plant Mol Biol 55:311–314

Kerff F, Amoroso A, Herman R, Sauvage E, Petrella S, Filée P, Charlier P, Joris B, Tabuchi A, Nikolaidis N (2008) Crystal structure and activity of bacillus subtilis YoaJ (EXLX1), a bacterial expansin that promotes root colonization. Proc Natl Acad Sci 105(44):16876–16881

Kihlman M, Wallberg O, Stigsson L, Germgård U (2011) Dissolution of dissolving pulp in alkaline solvents after steam explosion pretreatments: 11th EWLP, Hamburg, Germany, August 16–19, 2010.

Kim ES, Lee HJ, Bang WG, Choi IG, Kim KH (2009) Functional characterization of a bacterial expansin from Bacillus subtilis for enhanced enzymatic hydrolysis of cellulose. Biotechnol Bioeng 102(5):1342–1353

Kim IJ, Ko H-J, Kim T-W, Nam KH, Choi I-G, Kim KH (2013a) Binding characteristics of a bacterial expansin (Bs EXLX1) for various types of pretreated lignocellulose. Appl Microbiol Biotechnol 97:5381–5388

Kim IJ, Ko HJ, Kim TW, Choi IG, Kim KH (2013b) Characteristics of the binding of a bacterial expansin (BsEXLX1) to microcrystalline cellulose. Biotechnol Bioeng 110(2):401–407

Kim IJ, Lee HJ, Choi I-G, Kim KH (2014) Synergistic proteins for the enhanced enzymatic hydrolysis of cellulose by cellulase. Appl Microbiol Biotechnol 98:8469–8480

Kokta BV, Ahmed A (1993) Explosion pulping of eucalyptus: a comparison with CTMP and CMP. Wood Sci Technol 27(4):271–279. https://doi.org/10.1007/BF00195303

Kostag M, Gericke M, Heinze T, El Seoud OA (2019) Twenty-five years of cellulose chemistry: innovations in the dissolution of the biopolymer and its transformation into esters and ethers. Cellulose 26:139–184

Kumar A (2021) Dissolving pulp production: Cellulases and xylanases for the enhancement of cellulose accessibility and reactivity. Phys Sci Rev 6(5):111–129

Kumar D, Bhardwaj R, Jassal S, Goyal T, Khullar A, Gupta N (2021) Application of enzymes for an eco-friendly approach to textile processing. Environ Sci Pollut Res 1–11

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohyd Polym 90(2):735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Lee HJ, Lee S, Ko H-j, Kim KH, Choi I-G (2010) An expansin-like protein from Hahella chejuensis binds cellulose and enhances cellulase activity. Mol Cells 29:379–385

Lee HJ, Kim IJ, Kim JF, Choi I-G, Kim KH (2013) An expansin from the marine bacterium Hahella chejuensis acts synergistically with xylanase and enhances xylan hydrolysis. Biores Technol 149:516–519

Lee C, Dazen K, Kafle K, Moore A, Johnson DK, Park S, Kim SH (2016) Correlations of apparent cellulose crystallinity determined by XRD, NMR, IR, Raman, and SFG methods. Cellul Chem Prop Fibers Nanocelluloses Adv Mater 115–131

Li L-C, Bedinger PA, Volk C, Jones AD, Cosgrove DJ (2003) Purification and characterization of four β-expansins (Zea m 1 isoforms) from maize pollen. Plant Physiol 132(4):2073–2085

Lin H, Shen Q, Zhan J-M, Wang Q, Zhao Y-H (2013) Evaluation of bacterial expansin EXLX1 as a cellulase synergist for the saccharification of lignocellulosic agro-industrial wastes. PLoS ONE 8(9):e75022

Liu X, Liu C, Ma Y, Hong J, Zhang M (2014) Heterologous expression and functional characterization of a novel cellulose-disruptive protein LeEXP2 from Lycopersicum esculentum. J Biotechnol 186:148–155

Liu X, Ma Y, Zhang M (2015) Research advances in expansins and expansion-like proteins involved in lignocellulose degradation. Biotech Lett 37:1541–1551

Lohoff C, Buchholz PC, Le Roes-Hill M, Pleiss J (2021) Expansin engineering database: a navigation and classification tool for expansins and homologues. Proteins Struct Funct Bioinf 89(2):149–162

Lumiainen J (1998) Refining of chemical pulp. In: Paulapuro H (ed) papermaking part 1: stock preparation and wet End, vol 1. (2nd edn.), pp 86–122

Martino DC, Colodette JL, Chandra R, Saddler J (2017) Steam explosion pretreatment used to remove hemicellulose to enhance the production of a eucalyptus organosolv dissolving pulp. Wood Sci Technol 51:557–569

Martin-Sampedro R, Eugenio ME, Moreno JA, Revilla E, Villar JC (2014) Integration of a kraft pulping mill into a forest biorefinery: pre-extraction of hemicellulose by steam explosion versus steam treatment. Biores Technol 153:236–244

McQueen-Mason S, Cosgrove DJ (1994) Disruption of hydrogen bonding between plant cell wall polymers by proteins that induce wall extension. Proc Natl Acad Sci 91(14):6574–6578

McQueen-Mason SJ, Cosgrove DJ (1995) Expansin mode of action on cell walls (analysis of wall hydrolysis, stress relaxation, and binding). Plant Physiol 107(1):87–100

Meng X, Ragauskas AJ (2014) Recent advances in understanding the role of cellulose accessibility in enzymatic hydrolysis of lignocellulosic substrates. Curr Opin Biotechnol 27:150–158

Merino ST, Cherry J (2007) Progress and challenges in enzyme development for biomass utilization. Biofuels 95–120

Miao Q, Tian C, Chen L, Huang L, Zheng L, Ni Y (2015) Combined mechanical and enzymatic treatments for improving the fock reactivity of hardwood kraft-based dissolving pulp. Cellulose 22:803–809

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials 6(5):1745–1766

Mojsov K (2011) Application of enzymes in the textile industry: a review.

Molenveld K, Slaghek TM (2022) Recent developments in biodegradable cellulose‐based plastics. Biodegrad Polym Circ Plast Econ 273–298

Monschein M, Ioannou E, Koitto T, Al Amin LA, Varis JJ, Wagner ER, Mikkonen KS, Cosgrove DJ, Master ER (2023) Loosenin-like proteins from phanerochaete carnosa impact both cellulose and chitin fiber networks. Appl Environ Microbiol 89(1):e01863-e11822

Ogiwara Y, Arai K (1968) Swelling degree of cellulose materials and hydrolysis rate with cellulase. Text Res J 38(9):885–891

Okano T, Sarko A (1985) Mercerization of cellulose. II. Alkali—cellulose intermediates and a possible mercerization mechanism. J Appl Polym Sci 30(1):325–332

Olarte-Lozano M, Mendoza-Nunez MA, Pastor N, Segovia L, Folch-Mallol J, Martinez-Anaya C (2014) PcExl1 a novel acid expansin-like protein from the plant pathogen pectobacterium carotovorum, binds cell walls differently to BsEXLX1. PLoS ONE 9(4):e95638

Østby H, Hansen LD, Horn SJ, Eijsink VG, Várnai A (2020) Enzymatic processing of lignocellulosic biomass: principles, recent advances and perspectives. J Ind Microbiol Biotechnol Off J Soc Ind Microbiol Biotechnol 47(9–10):623–657

Ott E, Spurlin HM, Grafflin MW (eds) (1954) Cellulose and cellulose derivatives, 2nd edn. Interscience, New York, p 556

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8(6):1934–1941

Palme A, Theliander H, Brelid H (2016) Acid hydrolysis of cellulosic fibres: comparison of bleached kraft pulp, dissolving pulps and cotton textile cellulose. Carbohyd Polym 136:1281–1287

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1–10

Pere J, Tammelin T, Niemi P, Lille M, Virtanen T, Penttila PA, Ahvenainen P, Gronqvist S (2020) Production of high solid nanocellulose by enzyme-aided fibrillation coupled with mild mechanical treatment. ACS Sustain Chem Eng 8(51):18853–18863

Quiroz-Castañeda RE, Martínez-Anaya C, Cuervo-Soto LI, Segovia L, Folch-Mallol JL (2011) Loosenin, a novel protein with cellulose-disrupting activity from Bjerkandera adusta. Microb Cell Fact 10:1–9

Rahikainen J, Ceccherini S, Molinier M, Holopainen-Mantila U, Reza M, Väisänen S, Puranen T, Kruus K, Vuorinen T, Maloney T (2019) Effect of cellulase family and structure on modification of wood fibres at high consistency. Cellulose 26:5085–5103

Romão S, Bettencourt A, Ribeiro IA (2022) Novel features of cellulose-based films as sustainable alternatives for food packaging. Polymers 14(22):4968

Salmela J, Widmaier T, Kuosmanen P, Kiviluoma P, Liukkonen J, Koskinen H, Stark T, Isomaa T, Lehto J (2016) Method and apparatus for producing fibre yarn (Patent No. US 20160160400 A1). Available at: http://patft1uspto gov/netacgi/nph-Parser

Saloheimo M, Paloheimo M, Hakola S, Pere J, Swanson B, Nyyssönen E, Bhatia A, Ward M, Penttilä M (2002) Swollenin, a trichoderma reesei protein with sequence similarity to the plant expansins, exhibits disruption activity on cellulosic materials. Eur J Biochem 269(17):4202–4211

Seki Y, Kikuchi Y, Yoshimoto R, Aburai K, Kanai Y, Ruike T, Iwabata K, Goitsuka R, Sugawara F, Abe M (2015) Promotion of crystalline cellulose degradation by expansins from Oryza sativa. Planta 241:83–93

Senthilkumar V, Gunasekaran P (2005) Bioethanol production from cellulosic substrates: Engineered bacteria and process integration challenges

Strunk P, Eliasson B, Hägglund C, Agnemo R (2011) Chemical pulping: the influence of properties in cellulose pulps on the reactivity in viscose manufacturing. Nord Pulp Pap Res J 26(1):81–89

Tian C, Zheng L, Miao Q, Cao C, Ni Y (2014) Improving the reactivity of kraft-based dissolving pulp for viscose rayon production by mechanical treatments. Cellulose 21:3647–3654

Tomasec M, Kokta B (1991) Steam explosion pulping: effects of temperature and pressure on paper properties at constant pulp yield and ionic content. Tappi J 74(12):119–125

Tong X, He Z, Zheng L, Pande H, Ni Y (2023) Enzymatic treatment processes for the production of cellulose nanomaterials: a review. Carbohydr Polym 299:120199

Tovar-Herrera OE, Batista-García RA, Sánchez-Carbente MdR, Iracheta-Cárdenas MM, Arévalo-Niño K, Folch-Mallol JL (2015) A novel expansin protein from the white-rot fungus schizophyllum commune. PLoS ONE 10(3):e0122296

Trache D, Tarchoun AF, Derradji M, Hamidon TS, Masruchin N, Brosse N, Hussin MH (2020) Nanocellulose: from fundamentals to advanced applications. Front Chem 8:392

Vanhatalo KM, Dahl OP (2014) Effect of mild acid hydrolysis parameters on properties of microcrystalline cellulose. BioResources 9(3):4729–4740

Várnai A, Siika-Aho M, Viikari L (2013) Carbohydrate-binding modules (CBMs) revisited: reduced amount of water counterbalances the need for CBMs. Biotechnol Biofuels 6(1):1–12

Vehviläinen M, Määttänen M, Grönqvist S, Harlin A, Steiner M, Kunkel R (2020) Sustainable continuous process for cellulosic regenerated fibers. Chem Fibers Int 70:128–130

Viikari L, Kantelinen A, Sundquist J, Linko M (1994) Xylanases in bleaching: from an idea to the industry. FEMS Microbiol Rev 13(2–3):335–350

Wang Y, Tang R, Tao J, Gao G, Wang X, Mu Y, Feng Y (2011) Quantitative investigation of non-hydrolytic disruptive activity on crystalline cellulose and application to recombinant swollenin. Appl Microbiol Biotechnol 91:1353–1363

Wang W, Liu C, Ma Y, Liu X, Zhang K, Zhang M (2014) Improved production of two expansin-like proteins in Pichia pastoris and investigation of their functional properties. Biochem Eng J 84:16–27

Wang Q, Liu S, Yang G, Chen J, Ni Y (2015b) High consistency cellulase treatment of hardwood prehydrolysis kraft based dissolving pulp. Biores Technol 189:413–416

Wang K, Chen J, Sun S-N, Sun R-C (2015a) Steam explosion. In: Pretreatment of biomass. Elsevier, pp 75–104

Yennawar NH, Li L-C, Dudzinski DM, Tabuchi A, Cosgrove DJ (2006) Crystal structure and activities of EXPB1 (Zea m 1), a β-expansin and group-1 pollen allergen from maize. Proc Natl Acad Sci 103(40):14664–14671

You X, Chen F, Ma Y, Roselli A, Enqvist E, Hassi H (2021) Single fiber swelling behavior for natural and man-made cellulose fibers under alkaline treatment. Cellulose 28(18):11287–11298

Zhou Q, Lv X, Zhang X, Meng X, Chen G, Liu W (2011) Evaluation of swollenin from Trichoderma pseudokoningii as a potential synergistic factor in the enzymatic hydrolysis of cellulose with low cellulase loadings. World J Microbiol Biotechnol 27:1905–1910

Zhou Z, Liu D, Zhao X (2021) Conversion of lignocellulose to biofuels and chemicals via sugar platform: an updated review on chemistry and mechanisms of acid hydrolysis of lignocellulose. Renew Sustain Energy Rev 146:111169

Acknowledgments

Not applicable

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 964764. The content presented in this document represents the views of the authors, and the Commission is not responsible for any use that may be made of the information it contains.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hiltunen, S., Sapkota, J., Ioannou, E. et al. Comparative assessment of chemical and biochemical approaches for the activation of lignocellulosic materials and emerging opportunities for expansin-related proteins. Cellulose 31, 147–168 (2024). https://doi.org/10.1007/s10570-023-05637-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05637-3