Abstract

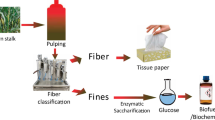

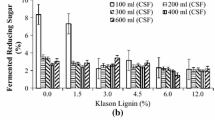

In this work, a compound enzyme treated cotton stalk chemi-mechanical pulp (CE-CSCMP) that could improve the properties of wastepaper pulp was investigated. Firstly, according to whether the enzymes (cellulase, xylanase, pectinase and lipase) could promote the mechanical properties of cotton stalk chemi-mechanical pulp (CSCMP) paper, xylanase, pectinase and lipase were selected to prepare compound enzyme. Afterwards, the underlying mechanism of enzymatic treatment of CSCMP was elucidated through the loss of cellulose, hemicellulose and lignin. Single enzymes, such as xylanase, pectinase or lipase, could only directly act on one substrate when treating CSCMP, while non-enzymatic substrates could impede the hydrolysis of the substrate. Therefore, the exposure area of cellulose was small, and the improvement of CSCMP paper strength was limited. It is found that there was a synergistic interaction between the three components in the compound enzyme, leading to a higher hydrolysis efficiency compared to that of single enzyme. Consequently, the area available for hydrogen bonding on the fiber surface was greatly increased, and CE-CSCMP obtained the best paper properties. Finally, CSCMP were furnished with wastepaper pulp, which resulted obvious improvement of the tensile strength, tear strength and ring compressive strength of wastepaper pulp. In conclusion, CE-CSCMP was a high-yield pulp of non-wood raw materials with better performance and could be used to improve wastepaper pulp.

Similar content being viewed by others

Availability of data and materials

Raw data will be available up request from the corresponding authors.

References

Bari E et al (2021) Characterizing fungal decay of beech wood: potential for biotechnological applications. Microorganisms 9:247. https://doi.org/10.3390/microorganisms9020247

Basu S, Omadjela O, Gaddes D, Tadigadapa S, Zimmer J, Catchmark JM (2016) Cellulose microfibril formation by surface-tethered cellulose synthase enzymes. ACS Nano 10:1896–1907. https://doi.org/10.1021/acsnano.5b05648

Bernaoui A, Lebrun G, Ruiz E (2022) High performance natural fiber composites from mat and UD flax reinforcements backed with a mat Binder: a study of mat fiber surface fibrillation. Compos Part A-Appl S 160:107064–107116. https://doi.org/10.1016/j.compositesa.2022.107064

Bidlack J, Malone M, Benson R (1992) Molecular structure and component integration of secondary cell walls in plants. Proc Okla Acad Sci 72:51–56

Chandra RP, Wu J, Saddler JN (2019) The Application of fiber quality analysis (FQA) and cellulose accessibility measurements to better elucidate the impact of fiber curls and kinks on the enzymatic hydrolysis of fibers. Acs Sustain Chem Eng 7:8827–8833. https://doi.org/10.1021/acssuschemeng.9b00783

Fang H, Lanouette R, Law KN (2011) Characterization of jack pine early- and latewood fibers in thermomechanical pulping. Ind Eng Chem Res 50:13396–13402. https://doi.org/10.1021/ie2019992

Ferdous T, Ni Y, Quaiyyum MA, Uddin MN, Jahan MS (2021) Non-wood fibers: relationships of fiber properties with pulp properties. ACS Omega 6:21613–21622. https://doi.org/10.1021/acsomega.1c02933

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Gabhane J, William S, Vaidya AN, Das S, Wate SR (2015) Solar assisted alkali pretreatment of garden biomass: effects on lignocellulose degradation, enzymatic hydrolysis, crystallinity and ultra-structural changes in lignocellulose. Waste Manage 40:92–99. https://doi.org/10.1016/j.wasman.2015.03.002

Guzmán-Delgado P, Graça J, Cabral V, Gil L, Fernández V (2016) The presence of cutan limits the interpretation of cuticular chemistry and structure: Ficus elastica leaf as an example. Physiol Plantarum 157:205–220. https://doi.org/10.1111/ppl.12414

Jele TB, Lekha P, Sithole B (2021) Role of cellulose nanofibrils in improving the strength properties of paper: a review. Cellulose 29:55–81. https://doi.org/10.1007/s10570-021-04294-8

Jky A, Yby A, Cw A, Wdc A, Lxw A, Yan Y, Hnzb C (2020) Production, physicochemical characteristics, and in vitro biological activities of polysaccharides obtained from fresh bitter gourd (Momordica charantia L.) via room temperature extraction techniques. Food Chem 337:1–10. https://doi.org/10.1016/j.foodchem.2020.127798

Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis. L. Carbohyd Polym 186:332–343. https://doi.org/10.1016/j.carbpol.2018.01.072

Kaur U, Oberoi HS, Bhargav VK, Sharma-Shivappa R, Dhaliwal SS (2012) Ethanol production from alkali- and ozone-treated cotton stalks using thermotolerant Pichia kudriavzevii HOP-1. Ind Crop Prod 37:219–226. https://doi.org/10.1016/j.indcrop.2011.12.007

Kaur P, Bhardwaj NK, Sharma J (2021) A study elucidating the relation between cellulose dissolution and crystallinity after cellulase treatment at different doses. 3 Biotech 11:371. https://doi.org/10.1007/s13205-021-02920-7

Kruer-Zerhusen N, Cantero-Tubilla B, Wilson DB (2017) Characterization of cellulose crystallinity after enzymatic treatment using Fourier transform infrared spectroscopy (FTIR). Cellulose 25:37–48. https://doi.org/10.1007/s10570-017-1542-0

Li G, Yu Y, Zhao Z, Li J, Li C (2003) Properties study of cotton stalk fiber/gypsum composite. Cement Concrete Res 33:43–46. https://doi.org/10.1016/s0008-8846(02)00915-8

Li Y-Y, Wang B, Wang B, Ma M-G (2018) The enhancement performances of cotton stalk fiber/PVC composites by sequential two steps modification. J Appl Polym Sci 135:46090. https://doi.org/10.1002/app.46090

Lin X, Wu Z, Zhang C, Liu S, Nie S (2018) Enzymatic pulping of lignocellulosic biomass. Ind Crop Prod 120:16–24. https://doi.org/10.1016/j.indcrop.2018.04.033

Liu YY, Liu MR, Li HL, Li BY, Zhang CH (2016) Characteristics of high yield pulp fibers by xylanase treatment. Cellulose 23:1–9. https://doi.org/10.1007/s10570-016-1032-9

Liu G, Yao W, Pang J, Yi H (2022) Study on the mechanical properties and thermal conductivity of cotton stalk fiber heat-insulating shotcrete. Adv Mater Sci Eng 2022:1–9. https://doi.org/10.1155/2022/3130276

Martín-Sampedro R, Fillat Ú, Ibarra D, Eugenio ME (2015) Towards the improvement of Eucalyptus globulus chemical and mechanical pulping using endophytic fungi. Int Biodeter Biodegr 105:120–126. https://doi.org/10.1016/j.ibiod.2015.08.023

Mboowa D (2021) A review of the traditional pulping methods and the recent improvements in the pulping processes. Biomass Convers Bior. https://doi.org/10.1007/s13399-020-01243-6

Moreira LR, Filho EX (2016) Insights into the mechanism of enzymatic hydrolysis of xylan. Appl Microbiol Biotechnol 100:5205–5214. https://doi.org/10.1007/s00253-016-7555-z

Nazhad MM, Paszner L (1994) Fundamentals of strength loss in recycled paper. Tappi J 77:171–179. https://doi.org/10.14288/1.0088893

Qifeng Yang HZ, Wang S, Li K, Shiyu Fu (2008) Bio-modification of eucalyptus chemithermomechanical pulp. Front Chem Eng China 2:28–33. https://doi.org/10.1007/s11705-008-0007-2

Razali NAM et al (2022) Comparative study on extraction of cellulose fiber from rice straw waste from chemo-mechanical and pulping method. Polymers 14:387. https://doi.org/10.3390/polym14030387

Rn A, Nkb B, Opm B, Rm A (2021) Cleaner bio-pulping approach for the production of better strength rice straw paper. J Clean Prod. https://doi.org/10.1016/j.jclepro.2021.128539

Sadeghifar H, Ragauskas A (2020) Perspective on technical lignin fractionation. Acs Sustain Chem Eng 8:8086–8101. https://doi.org/10.1021/acssuschemeng.0c01348

Satapathy S, Rout JR, Kerry RG, Thatoi H, Sahoo SL (2020) Biochemical prospects of various microbial pectinase and pectin: an approachable concept in pharmaceutical bioprocessing. Front Nutr 7:117. https://doi.org/10.3389/fnut.2020.00117

Scheller HV, Ulvskov P (2010) Hemicelluloses. Annurevplant Biol 61:263–289. https://doi.org/10.1021/acssuschemeng.0c01348

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Sharma D, Chaudhary R, Kaur J, Arya SK (2020) Greener approach for pulp and paper industry by Xylanase and Laccase. Biocatal Agr Biotech 25:101604. https://doi.org/10.1016/j.bcab.2020.101604

Singh A, Bajar S, Bishnoi NR (2017) Physico-chemical pretreatment and enzymatic hydrolysis of cotton stalk for ethanol production by Saccharomyces cerevisiae. Bioresour Technol 244:71–77. https://doi.org/10.1016/j.biortech.2017.07.123

Tanabe H, Kobayashi Y (1987) Effect of lignin-carbohydrate complex on maceration of mitsumata (Edgeworthia papyrifera Sieb, et Zucc.) bast by pectinolytic enzymes from erwinia carotovora. Holzforschung 41:395–399. https://doi.org/10.1515/hfsg.1987.41.6.395

Turumtay H (2015) Cell wall engineering by heterologous expression of cell wall-degrading enzymes for better conversion of lignocellulosic biomass into biofuels. Bioenerg Res 8:1574–1588. https://doi.org/10.1007/s12155-015-9624-z

Varghese LM, Agrawal S, Nagpal R, Mishra OP, Mahajan R (2020) Eco-friendly pulping of wheat straw using crude xylano-pectinolytic concoction for manufacturing good quality paper. Environ Sci Pollut R 27:34574–34582. https://doi.org/10.1007/s11356-020-10119-1

Waham WA et al (2015) Pulping process and the potential of using non-wood pineapple leaves fiber for pulp and paper production: a review. J Nat Fibers 13:85–102. https://doi.org/10.1080/15440478.2014.984060

Wei S, Liu K, Ji X, Wang T, Wang R (2021) Application of enzyme technology in biopulping and biobleaching. Cellulose 28:10099–10116. https://doi.org/10.1007/s10570-021-04182-1

Xie F, Gong S, Zhang W, Wang Z (2020) Kinetics and molecular docking studies of activating effect of canna edulis ker residue lignin on the activity of lipase. Starch 73:2000154. https://doi.org/10.1002/star.202000154

Xu E, Wang D, Lin L (2020) Chemical structure and mechanical properties of wood cell walls treated with acid and alkali solution. Forests 11:87. https://doi.org/10.3390/f11010087

Yang G, Jahan MS, Liu H, Ni Y (2012) Acid Hydrolysis of prehydrolysis liquor produced from the kraft-based dissolving pulp production process. Ind Eng Chem Res 51:13902–13907. https://doi.org/10.1021/ie3023059

Yeats TH, Rose JK (2013) The formation and function of plant cuticles. Plant Physiol 163:5–20. https://doi.org/10.1104/pp.113.222737

Zhao J, Dong Z, Li J, Chen L, Bai Y, Jia Y, Shao T (2018) Ensiling as pretreatment of rice straw: the effect of hemicellulase and Lactobacillus plantarum on hemicellulose degradation and cellulose conversion. Bioresour Technol 266:158–165. https://doi.org/10.1016/j.biortech.2018.06.058

Acknowledgments

Not applicable.

Funding

This work was supported by National Key R&D Program of China, Grant No. 2019YFC1905900, the National Natural Science Foundation of China (Grant No. 32230070), Natural Science Foundation of Shandong Province of China (Grant No. ZR2021ZD38), Jinan Innovation Team (Grant No. 2021GXRC023), the QUTJBZ Program (No. 2022JBZ01-05), and Taishan Scholars Program.

Author information

Authors and Affiliations

Contributions

ZX: Data curation, Writing—original draft. ZT and QZ: Data curation, Conceptualization, Supervision. X-XJ and DW: Writing-review & editing, Project administration, Funding acquisition. RW: Formal analysis, Investigation, Validation, Visualization.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Consent for publication

Written informed consent for publication was obtained from all participants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, Z., Tian, Z., Zhao, Q. et al. A compound enzyme with synergistic interaction to treat cotton stalk chemi-mechanical pulp to improve the properties of wastepaper pulp. Cellulose 30, 9013–9026 (2023). https://doi.org/10.1007/s10570-023-05298-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05298-2