Abstract

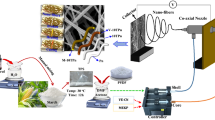

In this study, maleated chitin nanofibers (MCNFs)-poly (vinyl alcohol) (PVA) composite films were fabricated to evaluate the reinforcement effect of MCNFs to PVA. Maleated chitin nanofibers (MCNFs) were prepared by esterification of α-chitin powder with maleic anhydride and 2 passes grinder treatment. The average diameter of MCNFs was about 10 nm. The PVA-MCNF composites films were prepared by solution casting technique at 0, 1, 3, 5, 10 and 15 wt% of MCNFs. The FTIR and XRD analyses revealed that, there were strong interaction between MCNFs and PVA. The nanocomposite films displayed nearly similar transparency level of PVA film suggesting that the MCNFs were dispersed at the nanoscale range. Both the DSC and TGA analyses have shown that, thermal stability of PVA was significantly enhanced upon inclusion of MCNFs. The tensile testing data also indicated that, the Young’s modulus, tensile strength, elongation at break and toughness of PVA were increased by 71.87%, 41.47%, 49.10% and 261.20%, respectively through incorporation of 3 wt% MCNFs into the PVA matrix. The maximum swelling index of PVA film in deionized water (195%) was reduced to 141% for 3 wt% MCNFs containing composite film. The strong interfacial interactions between MCNFs and PVA were the decisive factors for the betterment of PVA properties. Generally, this study demonstrates a substantial approach in making thermo-mechanically stable and less water sensitive biodegradable nanocomposite films to be applied in making flexible packaging and biomedical materials.

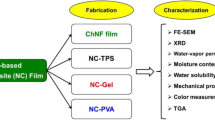

Graphic abstract

Similar content being viewed by others

References

Agarwal R, Alam MS, Gupta B (2013) Polyvinyl alcohol-polyethylene oxide-carboxymethyl cellulose membranes for drug delivery. J Appl Polym Sci 129:3728–3736. https://doi.org/10.1002/app.39144

Aklog YF, Nagae T, Izawa H, Morimoto M, Saimoto H, Ifuku S (2016) Preparation of chitin nanofibers by surface esterification of chitin with maleic anhydride and mechanical treatment. Carbohydr Polym 153:55–59. https://doi.org/10.1016/j.carbpol.2016.07.060

Aklog YF, Nagae T, Izawa H, Morimoto M, Saimoto H, Ifuku S (2017) Effect of grinder pretreatment for easy disintegration of Chitin into nanofiber. J Nanosci Nanotechnol 17:5037–5041. https://doi.org/10.1166/jnn.2017.14223

Alexander L (1979) In: Krieger AR (ed) X-ray diffraction methods in polymer science. New York: Huntington

Aslam M, Kalyar MA, Raza ZA (2018) Polyvinyl alcohol: areview of research status and use of polyvinyl alcohol based nanocomposites. Polym Eng Sci 58:2119–2132. https://doi.org/10.1002/pen.24855

Bai L, Gu J, Huan S, Li Z (2014) Aqueous poly(vinyl acetate)-based core/shell emulsion: synthesis, morphology, properties and application. RSC Adv 4:27363. https://doi.org/10.1039/c4ra03695f

Balla VK, Kate KH, Satyavolu J, Singh P, Tadimeti JGD (2019) Additive manufacturing of natural fiber reinforced polymer composites: processing and prospects. Compos B Eng 174:106956. https://doi.org/10.1016/j.compositesb.2019.106956

DeMerlis CC, Schoneker DR (2003) Review of the oral toxicity of polyvinyl alcohol (PVA). Food Chem Toxicol 41:319–326. https://doi.org/10.1016/S0278-6915(02)00258-2

Deng Q, Li J, Yang J, Li D (2014) Optical and flexible α-chitin nanofibers reinforced poly (vinyl alcohol)(PVA) composite film: fabrication and property. Compos Part A Appl Sci Manuf 67:55–60

Dong H, Strawhecker KE, Snyder JF, Orlicki JA, Reiner RS, Rudie AW (2012) Cellulose nanocrystals as a reinforcing material for electrospun poly (methyl methacrylate) fibers: formation, properties and nanomechanical characterization. Carbohyd Polym 87:2488–2495

Dufresne A (2010) Processing of polymer nanocomposites reinforced with polysaccharide nanocrystals. Molecules 15:4111–4128

Fan JB et al (2015) Directly coating hydrogel on filter paper for effective oil–water separation in highly acidic, alkaline, and salty environment. Adv Funct Mater 25:5368–5375

Fan Y, Fukuzumi H, Saito T, Isogai A (2012) Comparative characterization of aqueous dispersions and cast films of different chitin nanowhiskers/nanofibers. Int J Biol Macromol 50:69–76. https://doi.org/10.1016/j.ijbiomac.2011.09.026

Fan Y, Saito T, Isogai A (1923) 2008 Preparation of chitin nanofibers from squid pen β-Chitin by simple mechanical treatment under acid conditions. Biomacromolecules 9:1919. https://doi.org/10.1021/bm800178b

Fan Y, Saito T, Isogai A (2010) Individual chitin nano-whiskers prepared from partially deacetylated α-chitin by fibril surface cationization. Carbohydr Polym 79:1046–1051. https://doi.org/10.1016/j.carbpol.2009.10.044

Favier V, Chanzy H, Cavaillé J (1995) Polymer nanocomposites reinforced by cellulose whiskers Macromolecules 28:6365–6367

Frone AN, Panaitescu DM, Donescu D, Spataru CI, Radovici C, Trusca R, Somoghi R (2011) Preparation and characterization of pva composites with cellulose nanofibers obtained by ultrasonication 2011(6):26

Gaaz TS, Sulong AB, Akhtar MN, Kadhum AAH, Mohamad AB, Al-Amiery AA (2015) Properties and applications of polyvinyl alcohol, halloysite nanotubes and their nanocomposites. Molecules 20:22833–22847

Goodrich JD, Winter WT (2007) α-Chitin nanocrystals prepared from shrimp shells and their specific surface area measurement. Biomacromolecules 8:252–257. https://doi.org/10.1021/bm0603589

Gopalan Nair K, Dufresne A (2003) Crab shell chitin whisker reinforced natural rubber nanocomposites. Processing and swelling. Behav Biomacromol 4:657–665. https://doi.org/10.1021/bm020127b

Huan S, Bai L, Cheng W, Han G (2016) Manufacture of electrospun all-aqueous poly (vinyl alcohol)/cellulose nanocrystal composite nanofibrous mats with enhanced properties through controlling fibers arrangement and microstructure. Polymer 92:25–35

Ifuku S, Nogi M, Abe K, Yoshioka M, Morimoto M, Saimoto H, Yano H (2009) Preparation of chitin nanofibers with a uniform width as α-chitin from crab shells. Biomacromol 10:1584–1588

Ifuku S, Nogi M, Abe K, Yoshioka M, Morimoto M, Saimoto H, Yano H (2011) Simple preparation method of chitin nanofibers with a uniform width of 10–20 nm from prawn shell under neutral conditions. Carbohydr Polym 84:762–764

Ifuku S, Nogi M, Yoshioka M, Morimoto M, Yano H, Saimoto H (2010) Fibrillation of dried chitin into 10–20 nm nanofibers by a simple grinding method under acidic conditions. Carbohydr Polym 81:134–139

Ifuku S, Saimoto H (2012) Chitin nanofibers: preparations, modifications, and applications. Nanoscale 4:3308–3318

Irvin CW, Satam CC, Carson Meredith J, Shofner ML (2019) Mechanical reinforcement and thermal properties of PVA tricomponent nanocomposites with chitin nanofibers and cellulose nanocrystals. Compos A Appl Sci Manuf 116:147–157. https://doi.org/10.1016/j.compositesa.2018.10.028

Iyer KA, Schueneman GT, Torkelson JM (2015) Cellulose nanocrystal/polyolefin biocomposites prepared by solid-state shear pulverization: Superior dispersion leading to synergistic property enhancements. Polymer 56:464–475. https://doi.org/10.1016/j.polymer.2014.11.017

Jaiturong P, Sirithunyalug B, Eitsayeam S, Asawahame C, Tipduangta P, Sirithunyalug J (2018) Preparation of glutinous rice starch/polyvinyl alcohol copolymer electrospun fibers for using as a drug delivery carrier. Asian J Pharmaceut Sci 13:239–247

Jeyapragash R, Srinivasan V, Sathiyamurthy S (2020) Mechanical properties of natural fiber/particulate reinforced epoxy composites: areview of the literature. Mater Today Proc 22:1223–1227. https://doi.org/10.1016/j.matpr.2019.12.146

Jipa IM, Dobre L, Stroescu M, Stoica-Guzun A, Jinga S, Dobre T (2012) Preparation and characterization of bacterial cellulose-poly (vinyl alcohol) films with antimicrobial properties. Mater Lett 66:125–127

Kaur S, Dhillon GS (2015) Recent trends in biological extraction of chitin from marine shell wastes: a review. Crit Rev Biotechnol 35:44–61

Kim U-J, Eom SH, Wada M (2010) Thermal decomposition of native cellulose: influence on crystallite size. Polym Degrad Stab 95:778–781

Kuo S-W (2008) Hydrogen-bonding in polymer blends. J Polym Res 15:459–486

Lee H, Mensire R, Cohen RE, Rubner MF (2012) Strategies for hydrogen bonding based layer-by-layer assembly of poly(vinyl alcohol) with weak polyacids. Macromolecules 45:347–355. https://doi.org/10.1021/ma202092w

Lee S-Y, Mohan DJ, Kang I-A, Doh G-H, Lee S, Han SO (2009) Nanocellulose reinforced PVA composite films: effects of acid treatment and filler loading. Fibers Polym 10:77–82. https://doi.org/10.1007/s12221-009-0077-x

Lim M, Kwon H, Kim D, Seo J, Han H, Khan SB (2015) Highly-enhanced water resistant and oxygen barrier properties of cross-linked poly (vinyl alcohol) hybrid films for packaging applications. Prog Organ Coat 85:68–75

Lu J, Wang T, Drzal LT (2008) Preparation and properties of microfibrillated cellulose polyvinyl alcohol composite materials. Compos A Appl Sci Manuf 39:738–746

Minke R, Blackwell J (1978) The structure of α-chitin. J Mol Biol 120:167–181

Paul DR, Robeson LM (2008) Polymer nanotechnology: Nanocompos Polym 49:3187–3204. https://doi.org/10.1016/j.polymer.2008.04.017

Peng C, Chen G (2018) Preparation and assessment of heat-treated α-chitin nanowhiskers reinforced poly(viny alcohol) film for packaging application. Materials (Basel) 11:1883. https://doi.org/10.3390/ma11101883

Peresin MS, Habibi Y, Zoppe JO, Pawlak JJ, Rojas OJ (2010) Nanofiber composites of polyvinyl alcohol and cellulose nanocrystals: manufacture and characterization. Biomacromol 11:674–681. https://doi.org/10.1021/bm901254n

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52:5–25. https://doi.org/10.1016/j.polymer.2010.11.042

Qua EH, Hornsby PR, Sharma HSS, Lyons G, McCall RD (2009) Preparation and characterization of poly(vinyl alcohol) nanocomposites made from cellulose nanofibers. J Appl Polym Sci 113:2238–2247. https://doi.org/10.1002/app.30116

Ramaraj B (2007) Crosslinked poly (vinyl alcohol) and starch composite films. II. Physicomechanical, thermal properties and swelling studies. J Appl Polym Sci 103:909–916

Salaberria AM, Diaz RH, Labidi J, Fernandes SC (2015) Role of chitin nanocrystals and nanofibers on physical, mechanical and functional properties in thermoplastic starch films. Food Hydrocolloids 46:93–102

Salaberria AM, Labidi J, Fernandes SC (2014) Chitin nanocrystals and nanofibers as nano-sized fillers into thermoplastic starch-based biocomposites processed by melt-mixing. Chem Eng J 256:356–364

Salas C, Nypelö T, Rodriguez-Abreu C, Carrillo C, Rojas OJ (2014) Nanocellulose properties and applications in colloids and interfaces. Curr Opin Colloid Interface Sci 19:383–396. https://doi.org/10.1016/j.cocis.2014.10.003

Selvi J, Parthasarathy V, Mahalakshmi S, Anbarasan R, Daramola MO, Senthil Kumar P (2020) Optical, electrical, mechanical, and thermal properties and non-isothermal decomposition behavior of poly(vinyl alcohol)–ZnO nanocomposites. Iran Polym J 29:411–422. https://doi.org/10.1007/s13726-020-00806-8

Shams MI, Ifuku S, Nogi M, Oku T, Yano H (2011) Fabrication of optically transparent chitin nanocomposites. Appl Phys A 102:325–331

Shang Y, Peng Y (2007) Research of a PVA composite ultrafiltration membrane used in oil-in-water. Desalination 204:322–327

Spagnol C, Fragal EH, Witt MA, Follmann HDM, Silva R, Rubira AF (2018) Mechanically improved polyvinyl alcohol-composite films using modified cellulose nanowhiskers as nano-reinforcement. Carbohyd Polym 191:25–34. https://doi.org/10.1016/j.carbpol.2018.03.001

Sriupayo J, Supaphol P, Blackwell J, Rujiravanit R (2005) Preparation and characterization of α-chitin whisker-reinforced poly(vinyl alcohol) nanocomposite films with or without heat treatment. Polymer 46:5637–5644. https://doi.org/10.1016/j.polymer.2005.04.069

Suh J-H, Shin J-W, Kim H-K, Kim H-S, Kim Y-W, Kang H-J (2010) Effect of poly (vinyl alcohol) adhesives on the dimensional stability of LCD polarizer. Polym Korea 34:560–564

Tang C, Liu H (2008) Cellulose nanofiber reinforced poly(vinyl alcohol) composite film with high visible light transmittance. Compos Part A Appl Sci Manuf 39:1638–1643. https://doi.org/10.1016/j.compositesa.2008.07.005

Thong CC, Teo DCL, Ng CK (2016) Application of polyvinyl alcohol (PVA) in cement-based composite materials: areview of its engineering properties and microstructure behavior. Constr Build Mater 107:172–180. https://doi.org/10.1016/j.conbuildmat.2015.12.188

Watthanaphanit A, Supaphol P, Tamura H, Tokura S, Rujiravanit R (2008) Fabrication, structure, and properties of chitin whisker-reinforced alginate nanocomposite fibers. J Appl Polym Sci 110:890–899. https://doi.org/10.1002/app.28634

Yihun FA, Ifuku S, Saimoto H, Izawa H, Morimoto M (2020) Highly transparent and flexible surface modified chitin nanofibers reinforced poly (methyl methacrylate) nanocomposites: mechanical, thermal and optical studies. Polymer 197:122497. https://doi.org/10.1016/j.polymer.2020.122497

Zeng J-B, He Y-S, Li S-L, Wang Y-Z (2012) Chitin whiskers: an overview. Biomacromolecules 13(1):11

Zhang W, Yang X, Li C, Liang M, Lu C, Deng Y (2011) Mechanochemical activation of cellulose and its thermoplastic polyvinyl alcohol ecocomposites with enhanced physicochemical properties. Carbohydr Polym 83:257–263. https://doi.org/10.1016/j.carbpol.2010.07.062

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6(754):761. https://doi.org/10.1002/adem.200400097

Acknowledgments

This research work would have not been possible without the support and guidance of some people at different stages. First I would like to thank Professor Hiroyuki Saimoto, Tottori University, Japan, for his genuine encouragement and guidance during the study. My special thanks go to Professor Shinsuke Ifuku, Tottori University, Japan, for his excellent supervision, suggestions and continuous motivations to throughout the study. Lastly, I would like to address my appreciation to Dr. Dagnachew Aklog Yihun, Bahir Dar University, Ethiopia, for his support on editing the manuscript.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not for profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yihun, F.A., Ifuku, S., Saimoto, H. et al. Thermo-mechanically improved polyvinyl alcohol composite films using maleated chitin nanofibers as nano-reinforcement. Cellulose 28, 2965–2980 (2021). https://doi.org/10.1007/s10570-021-03719-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03719-8