Abstract

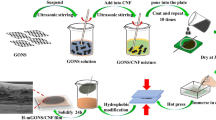

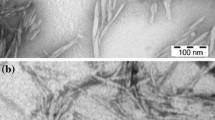

High strength regenerated cellulose/attapulgite (ATT) composite films (RC/ATT) with good oxygen barrier performance were prepared from cellulose/LiOH/urea solutions with different ATT contents ranging from 5 to 20 wt%. The synthesized RC/ATT films were characterized using UV–vis, XRD, scanning electron microscopy, TGA and mechanical testing. The results revealed the homogeneous distribution of ATT in the cellulose matrix. The tensile strength and Young’s modulus of the RC film were significantly improved from 86.9 MPa and 4.3 GPa to reach 127 MPa and 5 GPa as a result of the 5 wt% ATT reinforcement, respectively. The incorporation of ATT into the cellulose matrix could improve the thermal stability and water resistance of the RC film. Besides, the RC/ATT composite films exhibited relative low oxygen permeability below 0.5 cm3 μm/day m2 kPa, which could even reach 0.32 cm3 μm/day m2 kPa with 20 wt% ATT content. This work not only provided novel RC/ATT films as potential sustainable barrier packaging materials, but also shed light on the fabrication of other biopolymers based barrier packaging materials.

Similar content being viewed by others

References

Alcantara A, Darder M, Aranda P, Ruiz-Hitzky E (2014) Polysaccharide–fibrous clay bionanocomposites. Appl Clay Sci 96:2–8

Aulin C, Gallstedt M, Lindstrom T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Aulin C, Salazar-Alvarez G, Lindstrom T (2012) High strength, flexible and transparent nanofibrillated cellulose–nanoclay biohybrid films with tunable oxygen and water vapor permeability. Nanoscale 4:6622–6628

Bardet R, Reverdy C, Belgacem N, Leirset I, Syverud K, Bardet M, Bras J (2015) Substitution of nanoclay in high gas barrier films of cellulose nanofibrils with cellulose nanocrystals and thermal treatment. Cellulose 22:1227–1241

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548

Cai J, Zhang L (2006) Unique gelation behavior of cellulose in NaOH/urea aqueous solution. Biomacromol 7:183–189

Cai J, Zhang L, Zhou J, Qi H, Chen H, Kondo T, Chen X, Chu B (2007) Multifilament fibers based on dissolution of cellulose in NaOH/urea aqueous solution: structure and properties. Adv Mater 19:821–825

Cai J, Zhang L, Liu S, Liu Y, Xu X, Chen X, Chu B, Guo X, Xu J, Cheng H, Han C, Kuga S (2008) Dynamic self-assembly induced rapid dissolution of cellulose at low temperature. Macromolecules 41:9345–9351

Chanzy H, Dube M (1979) Crystallization of cellulose with N-methylmorpholine N-oxide: a new method of texturing cellulose. J Polym Sci Polym Lett Ed 17:219–226

Chen G, Fu G, Wang X, Gong X, Niu Y, Peng F, Yao C, Sun R (2017) Facile synthesis of high strength hot-water wood extract films with oxygen-barrier performance. Sci Rep 7:41075

Duan J, He X, Zhang L (2014) Magnetic cellulose–TiO2 nanocomposite microspheres for highly selective enrichment of phosphopeptides. Chem Commun 51:338–341

Eckelt J, Wolf B (2005) Membranes directly prepared from solutions of unsubstituted cellulose. Macromol Chem Phys 206:227–232

Fink H-P, Weigel P, Purz H, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO solutions. Prog Polym Sci 26:1473–1524

French A (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

He M, Kwok R, Wang Z, Duan B, Tang B, Zhang L (2014) Hair-inspired crystal growth of HOA in cavities of cellulose matrix via hydrophobic–hydrophilic interface interaction. ACS Appl Mater Inter 6:9508–9516

He M, Duan B, Xu D, Zhang L (2015) Moisture and solvent responsive cellulose/SiO2 nanocomposite materials. Cellulose 22:553–563

Heinze T, Dicke R, Koschella A, Kull A, Klohr E, Koch W (2000) Effective preparation of cellulose derivatives in a new simple cellulose solvent. Macromol Chem Phys 201:627–631

Hubbe M, Ferrer A, Tyagi P, Yin Y, Salas C, Pal L, Rojas O (2017) Nanocellulose in thin films, coatings, and plies for packaging applications: a review. BioResources 12:2143–2233

Khalil H, Davoudpour Y, Saurabh C, Hossain M, Adnan A, Dungani R, Paridah M, Sarker M, Fazita M, Syakir M, Haafiz M (2016) A review on nanocellulosic fibres as new material for sustainable packaging: process and applications. Renew Sust Energ Rev 64:823–836

Khalil H, Saurabh C, Tye Y, Lai T, Easa A, Rosamah E, Fazita M, Syakir M, Adnan A, Fizree H, Aprilia N, Banerjee A (2017) Seaweed based sustainable films and composites for food and pharmaceutical applications: a review. Renew Sust Energ Rev 77:353–362

Lavoine N, Desloses I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohyd Polym 90:735–764

Liang W, Wang Y, Sun H, Chen P, Zhu Z, Li A (2015) Superhydrophobic attapulgite-based films for the selective separation of oils and organic solvents from water. RSC Adv 5:105319–105323

Liao L, Li X, Wang Y, Fu H, Li Y (2016) Effects of surface structure and morphology of nanoclays on the properties of jatropha curcas oil-based waterborne polyurethane/clay nanocomposites. Ind Eng Chem Res 55:11689–11699

Liu A, Walther A, Ikkala O, Belova L, Berglund L (2011) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromol 12:633–641

Lue A, Zhang L, Ruan D (2007) Inclusion complex formation of cellulose in NaOH-Thiourea aqueous system at low temperature. Macromol Chem Phys 208:2359–2366

Mahmoudian S, Wahit M, Ismail A, Yussuf A (2012) Preparation of regenerated cellulose/montmorillonite nanocomposite films via ionic liquids. Carbohyd Polym 88:1251–1257

Miller K, Krochta J (1997) Oxygen and aroma barrier properties of edible films: a review. Trends Food Sci Tech 8:228–237

Moon R, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Ostlund A, Lundberg D, Nordstierna L, Holmberg K, Nyden M (2009) Dissolution and gelation of cellulose in TBAF/DMSO solutions: the roles of fluoride ions and water. Biomacromolecules 10:2401–2407

Peng L, Zhou L, Li Y, Pan F, Zhang S (2011) Synthesis and properties of waterborne polyurethane/attapulgite nanocomposites. Compos Sci Technol 71:1280–1285

Pinkert A, Marsh K, Pang S, Staiger M (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728

Rhim J, Park H, Ha C (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38:1629–1652

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Soheilmoghaddam M, Wahit M (2013) Development of regenerated cellulose/halloysite nanotube bionanocomposite films with ionic liquid. Int J Biol Macromol 58:133–139

Soheilmoghaddam M, Wahit M, Whye W, Akos N, Pour R, Yussuf A (2014) Bionanocomposites of regenerated cellulose/zeolite prepared using environmentally benign ionic liquid solvent. Carbohyd Polym 106:326–334

Song H, Zheng L (2013) Nanocomposite films based on cellulose reinforced with nano-SiO2: microstructure, hydrophilicity, thermal stability, and mechanical properties. Cellulose 20:1737–1746

Wang W, Wang A (2010) Nanocomposite of carboxymethyl cellulose and attapulgite as a novel pH-sensitive superabsorbent: synthesis, characterization and properties. Carbohyd Polym 82:83–91

Wang C, Wang Y, Liu W, Yin H, Yuan Z, Wang Q, Xie H, Cheng R (2012a) Natural fibrous nanoclay reinforced soy polyol-based polyurethane. Mater Lett 78:85–87

Wang H, Gurau G, Rogers R (2012b) Ionic liquid processing of cellulose. Chem Soc Rev 41:1519–1537

Wang C, Ding L, Wu Q, Liu F, Wei J, Lu R, Xie H, Cheng R (2014a) Soy polyol-based polyurethane modified by raw and silylated palygorskite. Ind Crop Prod 57:29–34

Wang C, Wu Q, Liu F, An J, Lu R, Xie H, Cheng R (2014b) Synthesis and characterization of soy polyol-based polyurethane nanocomposites reinforced with silylated palygorskite. Appl Clay Sci 101:246–252

Wang Q, Guo J, Xu D, Cai J, Qiu Y, Ren J, Zhang L (2015) Facile construction of cellulose/montmorillonite nanocomposite biobased plastics with flame retardant and gas barrier properties. Cellulose 22:3799–3810

Wang S, Lu A, Zhang L (2016) Recent advances in regenerated cellulose materials. Prog Polym Sci 53:169–206

Wu C, Saito T, Fujisawa S, Fukuzumi H, Isogai A (2012) Ultrastrong and high gas-barrier nanocellulose/clay-layered composites. Biomacromolecules 13:1927–1932

Xu B, Huang W, Pei Y, Chen Z, Kraft A, Reuben R, Hosson J, Fu Y (2009) Mechanical properties of attapulgite clay reinforced polyurethane shape-memory nanocomposites. Eur Polym J 45:1904–1911

Xu D, Cai J, Zhang L (2016) High strength cellulose composite films reinforced with clay for applications as antibacterial materials. Chin J Polym Sci 34:1281–1289

Yang Q, Fukuzumi H, Saito T, Isogai A, Zhang L (2011) Transparent cellulose films with high gas barrier properties fabricated from aqueous alkali/urea solutions. Biomacromol 12:2766–2771

Yang Q, Saito T, Isogai A (2012) Facile fabrication of transparent cellulose films with high water repellency and gas barrier properties. Cellulose 19:1913–1921

Yang Q, Wu C, Saito T, Isogai A (2014) Cellulose–clay layered nanocomposite films fabricated from aqueous cellulose/LiOH/urea solution. Carbohyd Polym 100:179–184

Youssef A, EL-Sayed S, Salama H, El-Sayed H, Dufresne A (2015) Evaluation of bionanocomposites as packaging material on properties of soft white cheese during storage period. Carbohyd Polym 132:274–285

Zhang J, Zhang J (2010) Advanced functional materials based on cellulose. Acta Polym Sin 12:1376–1398

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhang C, Liu R, Xiang J, Kang H, Liu Z, Huang Y (2014) Dissolution mechanism of cellulose in N, N-dimethylacetamide/lithium chloride: revisiting through molecular interactions. J Phys Chem B 118:9507–9514

Zhang J, Wu J, Yu J, Zhang X, He J, Zhang J (2017) Application of ionic liquids for dissolving cellulose and fabricating cellulose-based materials: state of the art and future trends. Mater Chem Front 1:1273–1290

Zhao D, Huang J, Zhong Y, Li K, Zhang L, Cai J (2016) High-strength and high-toughness double-cross-linked cellulose hydrogels: a new strategy using sequential chemical and physical cross-linking. Adv Funct Mater 26:6279–6287

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (Grant Nos. 51503177, 21774107 and 51603179), Top-notch Academic Programs Project of Jiangsu Higher Education Institutions (Grant No. PPZY2015A025), and Initial Scientific Research Foundation of Yancheng Institute of Technology (Grant No. KJC2014001) for financial support of this research.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, C., Shi, J., He, M. et al. High strength cellulose/ATT composite films with good oxygen barrier property for sustainable packaging applications. Cellulose 25, 4145–4154 (2018). https://doi.org/10.1007/s10570-018-1855-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1855-7