Abstract

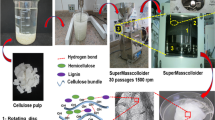

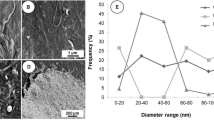

Cellulose nanofibers (CNF) have been suggested in the literature as a potential barrier coating layer for paper and paperboard. However, due to its rheological properties and solids content, the material is difficult to apply to paper at significant coat weight levels. The use of CNF as a coating to improve the structure and barrier properties of paperboard was investigated. Two forms of CNF were used: (1) refiner produced material and (2) material produced with an ultra-fine grinder. Carboxymethyl cellulose (CMC) was used for some samples as an additive. The rheology of these suspensions was characterized. These materials were applied onto the surface of paperboard using a draw-down rod coater in two layers. Scanning electron microscope (SEM) was used to see the coverage of the paper by the CNF layer. Air permeability, water penetration and barrier properties of the samples were characterized. The steady shear viscosity of CNF suspension decreased after the addition of CMC. Although CNF at 2% solid content without CMC could not be spread out onto the surface of paper uniformly, 3% CNF along with CMC was successfully coated on the surface of paper: CMC acts as a dispersant that produces a uniform suspension with minimal flocs. The ground CNF with CMC produced the best samples with good coverage as revealed by SEM images. The results show that the structure and barrier properties of coated paperboards improved considerably by the application of CNF coatings.

Similar content being viewed by others

References

Afra E, Mohammadnejad S, Saraeyan A (2016) Cellulose nanofibrils as coating matrial and its effect on paper properties. Prog Org Coat 101:455–460

Ahola S, Myllytie P, Osterberg M, Teerinen T, Laine J (2008) Effect of polymer adsorption on cellulose nanofibril water binding capacity and aggregation. BioResources 3(4):1315–1328

Anthony R, Xiang Z, Runge T (2015) Paper coating performance of hemicellulose-rich natural polymer from distiller’s grains. Prog Org Coat 89:240–245

ASTM Standard Test Method for Water Vapor Transmission of Materials, E96-95, 1995, ASTM International, http://www.astm.org

Aulin C, Gallstedt M, Lindstrom T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Aulin C, Salazar-Alvarez G, Lindstrom T (2012) High strength, flexible and transparent nanofibrillated cellulose-nanoclay biohybrid films with tunable oxygen and water vapor permeability. Nanoscale 4:6622–6628

Beghello L (1998) Some factors that influence fiber flocculation. Nord Pulp Pap Res J 13:272–279

Beghello L, Long LY, Eklund D (1997) Laboratory study on carboxymethyl cellulose as a wet-end additive in paperboard making. Pap Puu 79:55–57

Blomstedt M (2007) Modification of cellulosic fibers by carboxymethyl cellulose-effects on fibers and sheet properties. Dissertation, Helsinki University of Technology

Chen B, Zheng Q, Zhu J, Li J, Cai Z, Chen L, Gong S (2016) Mechanically strong fully biobased anisotropic cellulose aerogels. RSC Adv 6:96518–96526

Dimic-Misic K, Salo T, Paltakari J, Gane P (2014) Comparing the rheological properties of novel nanofibrillar cellulose-formulated pigment coating colours with those using traditional thickener. Nord Pulp Pap Res J 29(2):253–270

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. Walter de Gruyter GmbH 10

Fendler A, Villanueva MP, Giminez E, Lagaron JM (2007) Characterization of the barrier properties of composites of HDPE and purified cellulose fibers. Cellulose 14:427–438

Hamada H, Bousfield DW (2010) Nanofibrillated cellulose as a coating agent to improve print quality of synthetic fiber sheets. Tappi J 9(11):25–29

Hamada H, Mitsuhashi M (2016) Effect of cellulose nanofibers as a coating agent for woven and nonwoven fabrics. Nord Pulp Pap Res J 31(2):255–260

Hassan EA, Hassan ML, Abou-zeid RE, El-Wakil NA (2016) Novel nanofibrillated cellulose/chitosan nanoparticles nanocomposites films and their use for paper coating. Ind Crops and Prod 93:219–226

Johnson DA, Paradis MA, Bilodeau M, Crossley B, Foulger M, Gelinas P (2016) Effect of cellulosic nanofibrils on papermaking properties of fines papers. Tappi J 15(6):395–402

Kumar V, Bollstrom R, Yang A, Chen Q, Chen G, Salminen P, Bousfield DW, Toivakka M (2014) Comparison of nano and microfibrillated cellulose films. Cellulose 21:3443–3456

Laine J, Lindstrom T, Nordmark GG, Risinger G (2002) Studies on the topochemical modification of cellulosic fibers. Nord Pulp Pap Res J 17:50–56

Laivins GV, Scallan AM (1996) The influence of drying and beating on the swelling of fines. J Pulp Paper Sci 22(5):178–184

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15:425–433

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose – Its barrier properties and applications in cellulosic materials: A review. Carbohydr Polym 90:735–764

Lavoine N, Bras J, Desloges I (2014) Mechanical and barrier properties of cardboard and 3d packaging coated with microfibrillated cellulose. J Appl Polym Sci 131:40106

Liimatainen H, Haavisto S, Haapala A, Niinimaki J (2009) Influence of adsorbed and dissolved carboxymethyl cellulose on fiber suspension dispersing, dewater ability, and fines retention. BioResources 4(1):321–340

Nazari B (2015) New applications for cellulose nanofibers: Rheological challenges. Dissertation, University of Maine

Nazari B, Bousfield DW (2016) Cellulose nanofibers influence on properties and processing of paperboard coating. Nord Pulp Pap Res J 31(3):511–520

Pahimanolis N, Salminen A, Penttila PA et al (2013) Nanofibrillated cellulose/carboxymethyl cellulose composite with improved wet strength. Cellulose 20:1459–1468

Paunonen S (2013) Strength and barrier enhancements of cellophane and cellulose derivative films: A review. BioResources 8(2):3098–3121

Rautkoski H, Pajari H, Koskela H, Sneck A, Moilanen P (2015) Use of cellulose nanofibrils (CNF) in coating colors. Nord Pulp Pap Res J 30(3):511–518

Rezayati Charani P, Dehghani-Firouzabadi M, Afra E, Blademo A, Naderi A, Lindstrom T (2013) Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: microfibrillated cellulose paper. Cellulose 20:2559–2567

Richmond F, Haugwout C, Bousfield DW (2014) The use of cellulose nanofibers in paper coating formulation. TAPPI Paper Con

Schenker M, Schoelkopf J, Mangin P, Gane P (2016) Rheological investigation of complex micro and nanofibrillated cellulose (MNFC) suspension: Discussion of flow curves and gel stability. Tappi J 15(6):405–416

Song Z, Xiao H, Zhao Y (2014) Hydrophobic-modified nano-cellulose fiber/PLA biodegradable composites for lowering water vapor transmission rate (WVTR) of paper. Carbohydr Polym 111:442–448

Song Z, Xiao H, Li Y (2015) Effects of renewable materials coating on oil resistant properties of paper. Nord Pulp Pap Res J 30:344–349

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibers. Polym Int 47:291–294

TAPPI Standard Test Method for Grease Resistance Test for Paper and Paperboard (1996) Tappi press. Atlanta, GA

TAPPI Standard Test Method for Size Test for Paper by Ink Resistance (Hercules type method) (2007) Tappi press. Atlanta, GA

TAPPI Standard Test Method Gravimetric Methods for Measuring Dewatering of Coating Colors (Abo-Academi-type methods) (2001) Tappi press. Atlanta, GA

TAPPI Standrd Test Method for Air Resistance of Paper (Gurley method) (2006) Tappi press. Atlanta, GA

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Symp 37:815–827

Xu Y, Kuang Y, Salminen P, Chen G (2016) The influence of nano-fibrillated cellulose as a coating component in paper coating. BioResources 11(2):4342–4352

Yan H, Lindstrom T, Christiernin M (2006) Some ways to decrease fiber suspension flocculation and improve sheet formation. Nord Pulp Pap Res J 21:36–43

Yousefi H, Faezipour M, Hedjazi S, Mazhari Mousavi M, Azusa Y, Heidari A (2013) Comparative study of paper and nanopaper properties prepared from bacterial cellulose nanofibers and fiber/ground cellulose nanofibers of canola straw. Ind Crops and Prod 43:732–737

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79(4):1086–1093

Acknowledgments

The authors would like to thank the industrial sponsors of University of Maine Paper Surface Science Program (PSSP) for financial support and discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mazhari Mousavi, S.M., Afra, E., Tajvidi, M. et al. Cellulose nanofiber/carboxymethyl cellulose blends as an efficient coating to improve the structure and barrier properties of paperboard. Cellulose 24, 3001–3014 (2017). https://doi.org/10.1007/s10570-017-1299-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1299-5