Abstract

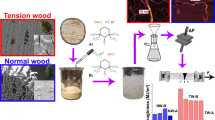

Well-dispersed cellulose II nanofibers with high purity of 92 % and uniform width of 15–40 nm were isolated from wood and compared to cellulose I nanofibers. First, ground wood powder was purified by series of chemical treatments. The resulting purified pulp was treated with 17.5 wt% sodium hydroxide (NaOH) solution to mercerize the cellulose. The mercerized pulp was further mechanically nanofibrillated to isolate the nanofibers. X-ray diffraction patterns revealed that the purified pulp had been transformed into the cellulose II crystal structure after treatment with 17.5 wt% NaOH, and the cellulose II polymorph was retained after nanofibrillation. The cellulose II nanofiber sheet exhibited a decrease in Young’s modulus (8.6 GPa) and an increase in fracture strain (13.6 %) compared to the values for a cellulose I nanofiber sheet (11.8 GPa and 7.5 %, respectively), which translated into improved toughness. The cellulose II nanofiber sheet also showed a very low thermal expansion coefficient of 15.9 ppm/K in the range of 20–150 °C. Thermogravimetric analysis indicated that the cellulose II nanofiber sheet had better thermal stability than the cellulose I nanofiber sheet, which was likely due to the stronger hydrogen bonds in cellulose II crystal structure, as well as the higher purity of the cellulose II nanofibers.

Similar content being viewed by others

References

Abe K, Yano H (2012) Cellulose nanofiber-based hydrogels with high mechanical strength. Cellulose 19:1907–1912

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8:3276–3278

Alvarez VA, Vazquez A (2006) Influence of fiber chemical modification procedure on the mechanical properties and water absorption of MaterBi/Sisal fiber composites. Compos Part A 37:1672–1680

Arvela PM, Anugwom I, Virtanen P, Sjöholm R, Mikkola JP (2010) Dissolution of lignocellulosic materials and its constituents using ionic liquids—a review. Ind Crop Prod 32:175–201

Blackwell J, Kolpak FJ, Gardner KH (1977) Structures of native and regenerated celluloses. ACS Symp Ser 48:42–55

Burger C, Hsiao BS, Chu B (2006) Nanofibrous materials and their applications. Annu Rev Mater Res 36:333–368

Chen WS, Yu HP, Liu YX, Hai YF, Zhang MX, Chen P (2011a) Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process. Cellulose 18:433–442

Chen WS, Yu HP, Liu YX, Chen P, Zhang MX, Hai YF (2011b) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83:1804–1811

Chen HZ, Wang N, Liu LY (2012) Regenerated cellulose membrane prepared with ionic liquid 1-butyl-3-methylimidazolium chloride as solvent using wheat straw. J Chem Technol Biotechnol 87:1634–1640

de Morais Teixeira E, Corrêa A, Manzoli A, de Lima Leite F, de Oliveira C, Mattoso L (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17(3):595–606

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I → cellulose II. Cellulose 9:7–18

Fengel D, Jakob H, Strobel C (1995) Influence of the alkali concentration on the formation of cellulose II. Holzforschung 49:505–511

Fink HP, Phillip B (1985) Models of cellulose physical structure from the view point of the cellulose I → II transition. J Appl Polym Sci 30:3779–3790

Goda K, Sreekala MS, Gomes A, Kaji T, Ohgi J (2006) Improvement of plant based natural fibers for toughening green composites—effect of load application during mercerization of ramie fibers. Compos Part A 37:2213–2220

Gomes A, Goda K, Ohgi J (2004) Effects of alkali treatment to reinforcement on tensile properties of curaua fiber green composites. JSME Int J, Ser A 47:541–546

Han JQ, Zhou CJ, French AD, Han GP, Wu QL (2013) Characterization of cellulose II nanoparticles regenerated from 1-butyl-3-methylimidazolium chloride. Carbohydr Polym 94:773–781

Hirota M, Tamura N, Saito T, Isogai A (2012) Cellulose II nanoelements prepared from fully mercerized, partially mercerized and regenerated celluloses by 4-acetamido-TEMPO/NaClO/NaClO2 oxidation. Cellulose 19:435–442

Ishikawa A, Okano T, Sugiyama J (1997) Fine structure and tensile properties of ramie fibers in the crystalline form of cellulose I, II, IIII and IVI. Polymer 38(2):463–468

Ishikura Y, Abe K, Yano H (2010) Bending properties and cell wall structure of alkali-treated wood. Cellulose 17:47–55

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89:461–466

Jin ZW, Wang S, Wang JQ, Zhao MX (2012) Effects of plasticization conditions on the structures and properties of cellulose packaging films from ionic liquid [BMIM]Cl. J Appl Polym Sci 125(1):704–709

Kabir MM, Wang H, Lau KT, Cardona F (2013) Effects of chemical treatments on hemp fibre structure. Appl Surf Sci 276:13–23

Kim HJ, Eom YG (2001) Thermogravimetric analysis of rice husk flour for a new raw material of lignocellulosic fiber-thermoplastic polymer composites. J Korean Wood Sci Technol 29:59–67

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Kuo CH, Lee CK (2009) Enhancement of enzymatic saccharification of cellulose by cellulose dissolution pretreatments. Carbohydr Polym 77:41–46

Murase H, Sugiyama J, Saiki H, Harada H (1988) The effect of lignin on mercerization of cellulose in wood: an electron diffraction study on the transformation from cellulose I to cellulose II. Mokuzai Gakkaishi 34(12):965–972

Nakagaito AN, Yano H (2008) Toughness enhancement of cellulose nanocomposites by alkali treatment of the reinforcing cellulose nanofibers. Cellulose 15:323–331

Nakano T (1989) Plasticization of wood by alkali treatment: relationship between plasticization and ultrastructure. Mokuzai Gakkaishi 35(5):431–437

Nishimura H, Sarko A (1987) Mercerization of cellulose. III. Changes in crystallite sizes. J Appl Polym Sci 33:855–866

Nishino T, Takano K, Nakamae K (1995) Elastic modulus of the crystalline regions of cellulose polymorphs. J Polym Sci, Part A: Polym Chem 33:1647–1651

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 20:1–4

O’Sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4:173–207

Okahisa Y, Abe K, Nogi M, Nakagaito AN, Nakatani T, Yano H (2011) Effects of delignification in the production of plant-based cellulose nanofibers for optically transparent nanocomposites. Compos Sci Technol 71:1342–1347

Okano T, Sarko A (1985) Mercerization of cellulose. II. alkali-cellulose intermediates and a possible mercerization mechanism. J Appl Polym Sci 30:325–332

Revol JF, Goring DAI (1981) On the mechanism of the mercerization of cellulose in wood. J Appl Polym Sci 26:1275–1282

Revol JF, Dietrich A, Goring DAI (1987) Effect of mercerization on the crystallite size and crystallinity index in cellulose from different sources. Can J Chem 65:1724–1725

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38:2046–2064

Sarko A, Muggli R (1974) Packing analysis of carbohydrates and polysaccharides. III. Valonia cellulose and cellulose IIla. Macromolecules 7:486–494

Shibazaki H, Kuga S, Okano T (1997) Mercerization and acid hydrolysis of bacterial cellulose. Cellulose 4:75–87

Shiraishi N, Moriwaki M, Lonikar SV, Yokota T (1984) Lattice conversion of cellulose in wood. J Wood Chem Technol 4(2):219–238

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Yang HP, Yan R, Chen HP, Lee DH, Zheng CG (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Yue YY, Zhou CJ, French AD, Xia G, Han GP, Wang QW, Wu QL (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19:1173–1187

Acknowledgments

This work was financially supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), the National Natural Science Foundation of China (NSFC 31170514, 31370557), Specialized Research Fund for the Doctoral Program of Higher Education of China (20113204110011).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, H., Li, D., Yano, H. et al. Preparation of tough cellulose II nanofibers with high thermal stability from wood. Cellulose 21, 1505–1515 (2014). https://doi.org/10.1007/s10570-014-0222-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0222-6