Abstract

Temperature has an important effect on the dissociative adsorption of molecular oxygen on platinum surfaces. Here, we show that if the substrate temperature is increased to 400–600 K, the total amount of oxygen loaded onto Pt(111) can be more than twice the well-established maximum coverage of 0.25 ML. While low energy electron diffraction and STM reveal a conventional p(2 × 2) structure of the topmost layer, temperature programmed desorption measurements indicate that additional oxygen is stored under the surface of platinum. Reactivity measurements show that this sub-surface oxygen layer does not lower the activity of such platinum surface towards CO oxidation. Therefore, while sub-surface oxygen layer does form under catalytically relevant temperatures on Pt(111), it has no great influence on the oxidizing ability of such surface. This sheds new light on the initial stages of platinum oxide formation, and may help bridge the understanding of catalytic oxidation of CO on Pt in ultra high vacuum and in high-pressure catalysis studies.

Graphical Abstract

Similar content being viewed by others

1 Introduction

Platinum is a primary catalyst for many oxidation reactions from fuel cells to automotive exhausts. The industrial and technological importance is reflected in the efforts by the scientific community to understand the interaction between the platinum surface and gas phase oxygen over the last four decades [1–11]. Although this effort has yielded a wealth of information, we show in this article that even the most intensely studied system, O2/Pt(111), can still yield surprising results that affect our view of the catalytic action under realistic conditions.

Studies of the interaction of the Pt(111) surface with molecular oxygen under ultra high vacuum (UHV) conditions show that if dosed at temperatures below 100 K, O2 adsorbs molecularly into the (3/2 × 3/2)R15° structure and a 0.44 monolayer (ML) O2 per Pt coverage. When temperature increases, adsorbed O2 partially desorbs and partially dissociates into chemisorbed atomic oxygen. While the desorbing O2 signal appears at 150 K during temperature programmed desorption (TPD) measurements [1, 2, 4, 6], remaining atomic oxygen forms the p(2 × 2) structure on the surface, clearly visible by low energy electron diffraction (LEED) [6]. This adsorbed atomic oxygen recombinatively desorbs at much higher temperatures with a maximum near 750 K on TPD spectra [1, 2, 4, 6].

The p(2 × 2) structure obtained by dissociating molecularly bound O2 can also be obtained by dosing O2 at room temperature [6, 8–10]. It has been shown that the dissociative adsorption of molecular oxygen on Pt(111) requires two next nearest unoccupied fcc threefold-hollow sites [11]. This limits the maximum coverage of a well-ordered overlayer to 0.25 ML of atomic oxygen, where O occupies every fourth fcc site [9, 10]. This overlayer has been extensively studied with UHV techniques and is often used as a starting point in studies of oxidation reactions on Pt(111) [3–5, 7–10, 12–14].

In contrast to O2, other oxygen sources require only one fcc site for dissociation [15]. Therefore, coverages up to 0.75 ML of atomic oxygen can be achieved by dissociation of NO2 on Pt(111) at 400 K [3, 16–18]. Even higher coverages (up to 2.5–2.9 ML) can be produced by exposure to more aggressive oxidants, such us ozone [19] and atomic oxygen [20, 21]. In combination with DFT calculations, it has been shown that oxygen adsorption on Pt(111) up to the coverage of 0.4–0.5 ML precedes the growth of a thicker platinum oxide layer [22–24].

Recently, a number of groups have combined preparation of single crystal or polycrystalline samples in UHV with reactivity studies at the relatively high pressure of (up to) 1 atm. Under these conditions, a thin layer of platinum oxide forms on the surface in the temperature range of 450–600 K [25]. Furthermore, apparently the platinum oxide surface has a higher turnover rate for CO oxidation then the metallic surface [26]. This oxide has been identified by X-ray diffraction as α-PtO2 [27, 28] which decomposes at temperatures between 700 and 800 K [29]. These results differ from those obtained in UHV studies as no oxide formation has been observed on platinum in a similar temperature range [1, 4, 6, 30–32]. It is also opportune to note that the formation of platinum “oxide” state has been reported previously, albeit at considerably higher temperatures (900–1,100 K) [33]. The same authors, however, had shortly thereafter re-assigned this effect to the oxidation of Si impurities in their platinum single crystals [34].

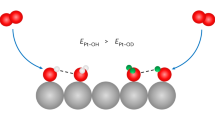

In this work we show that the 0.25 ML coverage limit for O2 dissociative adsorption on Pt(111) can be overcome even at high vacuum conditions, if oxygen exposure is conducted in the catalytically relevant temperature range 400–600 K. Our results indicate that oxygen adsorbs not only on the surface, but also migrates to the sub-surface region, so that additional oxygen is stored underneath the conventional 0.25 ML surface layer. While this subsurface oxygen has lower reactivity towards CO oxidation, its presence does not alter the reactivity of the surface-bound oxygen layer.

2 Experimental Section

Experiments were performed with two separate UHV systems using two Pt(111) single crystals. The fist home-built system with the base pressure 2 × 10−10 mbar was used for TPD measurements. It houses a 1 mm thick and 10 mm diameter Pt single crystal with its front surface cut and polished to <0.1° of the (111) plane [35]. The system is equipped with a quadrupole mass spectrometer (Balzers Prisma 200), LEED optics (LK Technologies RVL2000/8/R), sputtering gun, leak valves for background dosing and a differentially pumped manipulator with LN2 cooling. The sample temperature is measured with a chromel–alumel thermocouple spot-welded to the side of the crystal. A commercial filament is placed at the back side of the crystal. We use both radiative and electron bombardment heating with a PID controller (Eurotherm 2416). In combination with LN2 cooling, this yields accurate control of the sample temperature between 85 and 1,300 K.

The second (Omicron) system was used for STM measurements. It contains two separate chambers for preparation and analysis. Here, the sample is a 1 mm thick and 6 mm diameter Pt single crystal polished in a (111) orientation [35]. It is mounted in the sample holder with a filament facing the back side of the crystal. The preparation chamber is equipped for gas dosing and sputter-annealing treatment. The separate analysis chamber has a base pressure of 2 × 10−10 mbar and contains an electron gun (VG LEG 63), hemispherical electron analyzer for Auger electron spectroscopy (AES) (VG 100AX), LEED optics (VG RVL 900), a leak valve for gas dosing, and the Omicron STM.

The STM tips were prepared from the 0.25 mm tungsten wire by electrochemical etching in 2 M NaOH solution at 3 V DC voltage. Additional heating of the tip apex by a 100–500 μA electron emission current in UHV removes the oxide. This treatment yields stable emission currents in the 0.1–20 nA range. Tip conditioning is repeated daily and includes scanning a Au(100) surface while applying tunneling voltage pulses of 2–3 V to remove adsorbents and stabilize the tip until stable atomic resolution is obtained.

The (111) surfaces of both Pt single crystals were cleaned by repeated cycles of Ar sputtering, annealing in a 1–3 × 10−7 mbar O2 atmosphere at 900–1,000 K and annealing in vacuum at 1,100–1,200 K. The crystal surface quality in the home-built system was checked with LEED and by tracking the TPD of oxygen adsorbed at 85 K (until no traces of CO, CO2 or water were observed). The crystal in the STM system was cleaned until no traces of carbon were detected by AES and the STM gave atomically resolved clean Pt(111) surface with terrace widths of 20–100 nm.

Samples were exposed to O2 (Messer 5.0) and CO (Air Liquide 4.7) by background dosing at 3–6 × 10−7 and 1 × 10−8 mbar, respectively. In the Omicron system, the crystal surface was checked by STM in every experiment prior to O2 adsorption. Only when atomic resolution of a clean surface was achieved, the sample was transferred to the preparation chamber, exposed to O2 and placed back in the STM stage. For every individual TPD measurement, light Ar sputtering and annealing the crystal to 1,200 K in vacuum preceded oxygen adsorption.

The quarter monolayer atomic O coverage at 300 K was used as a calibration for the amount of desorbed oxygen during the TPDs, and as a reference structure for the LEED and STM measurements. All results were obtained by exposing a clean Pt(111) surface to 400 L of molecular O2 at various temperatures, and to 2.2 L of CO at 90 K unless noted otherwise (1 L = 1 × 10−6 Torr∙s). In all measurements O2 dosing was stopped and system was pumped down before cooling the crystal.

3 Results and Discussion

Figure 1 shows TPD spectra obtained after exposing the Pt(111) surface to 400 L O2 at different temperatures in the range 300–800 K. As the peak areas in these spectra are a direct measure of the amount of O adsorbed on the surface prior to the temperature ramp, it is clear that this amount depends non-linearly on the temperature at which the surface was exposed to O2. The TPD peak area increases with substrate temperature up to 500 K, and rapidly drops for higher dosing temperatures. Higher dosing temperatures induce an upward shift in the maximum desorption temperature. As the onset of O2 recombinant desorption lies at ~600 K, dosing oxygen at temperatures above 600 K simply leads to concomitant O2 desorption from the surface.

Figure 2 shows the integrated TPD peak areas versus adsorption temperature (circles). The error bars reflect one standard deviation obtained from multiple TPD measurements convoluted with the estimated error resulting from background subtraction. The black line only serves to guide the eye. Also, shown for comparison the uptake curve for atomic O on Pt(111) for oxidation at 300 K (squares). A Langmuirian fit for dissociative adsorption with an enforced asymptotic maximum of 0.25 ML is shown as a red line. The latter shows that 400 L results in (near) saturation for oxidation at 300 K.

Figure 2 demonstrates that by increasing the substrate temperature, the total amount of adsorbed O on Pt(111) can be at least twice as high as the 0.25 ML obtained for oxidation at 300 K. This result seems to be at odds with most results from previous UHV experiments as 0.25 ML was considered the maximum coverage when dosing molecular oxygen on Pt(111) [8–10, 13, 14]. However, the result is simultaneously not surprising considering recent reports of formation of an oxide layer on platinum single crystals and polycrystalline platinum for oxidation at atmospheric pressures (0.1–1 bar) in the temperature range 420–650 K [27, 28, 36]. Also, Derry and Ross [37] reported a similar observation for Pt(111) and Pt(100) surfaces. In their studies, platinum surfaces were exposed to ~40 and ~3,000 L O2 at 370 and 570 K respectively. While in the former case they obtained a coverage of ~0.2 ML, in the latter the amount of adsorbed oxygen was reported 3–5 times higher, which is very similar to our observations for Pt(111). We must also note that if we significantly increase the dose of O2 at 500 K, the desorption signal will exceed the ~0.55 ML shown in Fig. 2. We conclude that even at UHV conditions oxygen dosing well above room temperature allows the Pt(111) surface to take up considerably more than the equivalent of 0.25 ML of atomic oxygen.

In this light it is interesting to note that the exposure of platinum to 400 L O2 at 700 K leads to the adsorption of roughly the same amount of oxygen as exposure at 300 K, albeit with a significantly different desorption profile. In Fig. 3, we show both TPD traces as red and green lines, respectively. However, unlike the 0.25 ML oxygen covered surface created at 300 K, the surface with the same coverage created at 700 K remains active toward further oxygen adsorption when cooled back to room temperature. To demonstrate this, the surface was first exposed to 400 L of O2 at 700 K, then cooled to room temperature and exposed to the same amount of oxygen again at 300 K. The consecutively recorded TPD trace is shown as a black line in Fig. 3. The TPD peak area for the 700 + 300 K dose corresponds to an O coverage of 0.48 (±0.04) ML. As 0.25 ML is the maximum coverage that can be obtained for dissociation of O2 at 300 K, we conclude that during the initial high-temperature exposure, oxygen is adsorbed in positions that do not block sites for consecutive dissociative adsorption of O2 at 300 K.

Enhanced oxygen coverage was previously obtained on Pt(111) in a number of TPD studies in which NO2, O3 and O where used as the source of atomically adsorbed oxygen [19, 21, 38]. For low doses, oxygen adsorbs into the same p(2 × 2) structure as for O2 dosing at room temperature [8, 17, 38]. Higher doses lead to the formation of p(2 × 1) domains with a local 0.5 ML coverage [17]. TPD traces from these higher coverage show an additional O2 desorption peak at 500 K. The lower desorption temperature is suggested to result from repulsive interaction between oxygen atoms in the p(2 × 1) domains [21, 22, 38]. Our data in Figs. 1 and 3 do not show an additional peak at 500 K, even at oxygen coverage corresponding to ~0.5 ML. Instead, we observe an increase in the peak intensity at 710 K. These observations indicate that the oxygen-loaded surface resulting from exposure to O2 at higher temperatures is different from the p(2 × 1) overlayers observed in the O/O3/NO2 experiments.

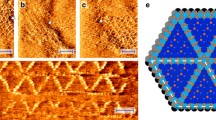

To investigate the surface structure of these high oxygen-covered platinum surfaces, we use LEED and STM. Figure 4 shows LEED patterns for Pt(111) exposed to O2 at 300 (a), 500 (b) and 700 K (c). Diffraction spots resulting from the clean Pt(111) surface are encircled. Although considerably weaker in Fig. 4c, all three images show an additional diffraction pattern that corresponds to a (2 × 2) structure [8]. We note that the Pt(111) surface covered mostly with p(2 × 1) oxygen domains yields a similar LEED pattern, while having twice the amount of oxygen on the surface [20, 21, 38]. Therefore, using LEED alone we cannot unambiguously identify the structure of the oxygen overlayer.

To visualize the surface structure locally and directly, we have performed STM topography measurements. Images in Fig. 5 were obtained for oxygen adsorbed on Pt(111) at 300 K (a) and 500 ± 50 K (b). Figure 5a and b both show the same p(2 × 2) structure of 0.25 ML of adsorbed atomic oxygen known from previous STM studies [13, 14]. This means that, although TPD data in Fig. 2 shows that the amount of oxygen adsorbed at 500 K is twice that for 300 K, it is not found in the top oxygen layer. Therefore we are left to conclude that additional oxygen created by exposure to O2 at elevated temperatures is stored below the surface of the metal. We note that contrary to the reported step-edge facilitated oxidation on Rh(111) at elevated temperatures [39], our STM study did not reveal surface buckling near the step edges corresponding to the oxide growth. We would like to emphasize that by using the term “subsurface oxygen” we refer only to the location of this additional oxygen, and perhaps “subsurface oxide” or “bulk oxide” would be better terminology, considering that oxides exist for most of the transition metals [40, 41]. Detailed XPS studies are planned in the near future to resolve any remaining ambiguity.

20 × 20 nm STM topography with fast Fourier transformation (FFT) insets for Pt(111) exposed to 400 L of O2 at room temperature (a) and 500 ± 50 K (b). Distortion in hexagonal order, which appears as a difference in inter-atomic distance on the FFT insets, is due to the constant drift always present in our STM

An unusual reactivity of the additional adsorbed atomic oxygen would support the subsurface oxygen hypothesis. To this end we have carried temperature programmed reaction (TPR) measurements to check how oxygen adsorbed on Pt(111) at various temperatures reacts with carbon monoxide. From previous studies it is known that the 0.25 ML of atomic oxygen on Pt(111) does not react with CO at temperatures below 150 K [5, 7]. CO and O co-adsorb in a 1:1 [42, 43] ratio and an increase in surface temperature activates the reaction that produces CO2. It has also been shown that covering the Pt(111) surface with atomic oxygen above 0.25 ML blocks adsorption of carbon monoxide [12, 44].

For the TPR traces shown in Fig. 6, CO was adsorbed at 90 K onto the Pt(111) surface pre-exposed to O2 at different temperatures. Subsequently, the sample temperature was ramped up while recording the partial pressures of m/e = 32 (O2), 28 (CO) and 44 (CO2). In line with previous studies [5, 7, 42, 43], we observe that for a surface saturated with O at 300 K, all CO as well as most of the oxygen react to form CO2. However, when the surface is initially oxidized at 500 K, some amount of CO as well as O2 are left the surface after the same amount of CO2 have been formed. At 700 K, even more CO desorbs at the expense of the CO2 formation. This is most unusual: we seem to have both O and CO on platinum surface, yet they refuse to react even at elevated temperatures! This clearly indicates that part of the atomic O created by high temperature adsorption is not available for CO oxidation. Considering the fact that unreacted CO desorbs at lower temperatures than unreacted O, it therefore supports our claim that the additional oxygen is absorbed in subsurface sites.

TPR spectra for a O2, b CO2 and c CO recorded after CO adsorption on Pt(111), pre-exposed to O2 at different temperatures. Figure 6a contains TPD traces of O2 for comparison. Heating rate is 4 K/s. Graphs are offset vertically for clarity

Finally, the observation that some oxygen remains unreacted even when CO is available on the surface and the temperature favors the oxidation reaction, suggests that sub-surface oxygen is thermodynamically quite stable even in the absence of oxygen in the top layer. We note that Rotermund et al. [45] already suggested thermodynamically stable subsurface oxygen to explain a change in work function for Pt(100) when the oxygen-covered surface was heated from 360 to 600 K. Furthermore, they observed desorption of the subsurface oxygen at 760 K, which is lower but comparable to what we observe for Pt(111), and the reactivity of subsurface O towards CO oxidation similar to ours [46].

4 Conclusions

The Pt(111) surface, when exposed to molecular oxygen at elevated temperatures (400–600 K), can dissociatively adsorb more oxygen than the previously assumed limit of 0.25 ML. While we show that this total amount can be even more than 0.5 ML, we find only 0.25 ML present on the surface. This makes us conclude that excess oxygen is stored below the surface of platinum. Its desorption temperature is equal to or higher than that of surface-bound oxygen, making it quite stable even in the absence of the latter. While non-reactive on its own, this sub-surface oxygen layer has no negative effect on the catalytic surface reactivity of platinum towards CO oxidation under conditions studied. While further studies are needed to determine its exact structure and chemical nature, this sub-surface oxygen is very likely the precursor of the stoichiometric α-PtO2 formed in catalytic reactors [27, 28] and as such provides an extra link between our understanding of catalytic oxidation reactions in UHV and in high pressure conditions.

References

Steininger H, Lehwald S, Ibach H (1982) Surf Sci 123:1

Avery NR (1983) Chem Phys Lett 96:371

Dahlgren D, Hemminger JC (1982) Surf Sci 123:L739

Gland JL (1980) Surf Sci 93:487

Gland JL, Kollin EB (1985) Surf Sci 151:260

Gland JL, Sexton BA, Fisher GB (1980) Surf Sci 95:587

Kinne M, Fuhrmann T, Zhu JF, Whelan CM, Denecke R, Steinruck HP (2004) J Chem Phys 120:7113

Materer N, Starke U, Barbieri A, Döll R, Heinz K, Van Hove MA, Somorjai GA (1995) Surf Sci 325:207

Mortensen K, Klink C, Jensen F, Besenbacher F, Stensgaard I (1989) Surf Sci 220:L701

Norton PR, Davies JA, Jackman TE (1982) Surf Sci 122:L593

Wintterlin J, Schuster R, Ertl G (1996) Phys Rev Lett 77:123

Mudiyanselage K, Yi C-W, Szanyi JN (2009) J Phys Chem C 113:5766

Volkening S, Bedurftig K, Jacobi K, Wintterlin J, Ertl G (1999) Phys Rev Lett 83:2672

Wintterlin J, Volkening S, Janssens TVW, Zambelli T, Ertl G (1997) Science 278:1931

Bartram ME, Windham RG, Koel BE (1988) Langmuir 4:240

Bartram ME, Windham RG, Koel BE (1987) Surf Sci 184:57

Devarajan SP, Hinojosa JA Jr, Weaver JF (2008) Surf Sci 602:3116

Jerdev DI, Kim J, Batzill M, Koel BE (2002) Surf Sci 498:L91

Saliba NA, Tsai YL, Panja C, Koel BE (1999) Surf Sci 419:79

Parkinson CR, Walker M, McConville CF (2003) Surf Sci 545:19

Weaver JF, Chen J-J, Gerrard AL (2005) Surf Sci 592:83

Hawkins JM, Weaver JF, Asthagiri A (2009) Phys Rev B 79:125434

Légaré P (2005) Surf Sci 580:137

Tang H, Van der Ven A, Trout BL (2004) Phys Rev B 70:045420

Chen MS, Cai Y, Yan Z, Gath KK, Axnanda S, Goodman DW (2007) Surf Sci 601:5326

Hendriksen BLM, Frenken JWM (2002) Phys Rev Lett 89:046101

Ackermann MD, Pedersen TM, Hendriksen BLM, Robach O, Bobaru SC, Popa I, Quiros C, Kim H, Hammer B, Ferrer S, Frenken JWM (2005) Phys Rev Lett 95:255505

Ellinger C, Stierle A, Robinson IK, Nefedov A, Dosch H (2008) J Phys Condens Matter 20:5

Maya L, Hagaman EW, Williams RK, Del Cul GD, Fiedor JN (1998) J Phys Chem B 102:1951

Bonzel HP, Ku R (1973) Surf Sci 40:85

Campbell CT, Ertl G, Kuipers H, Segner J (1981) Surf Sci 107:220

Nolan P (1999) J Chem Phys 111:3696

Niehus H, Comsa G (1980) Surf Sci 93:L147

Niehus H, Comsa G (1981) Surf Sci Lett 102:L14

Single crystals supplied by Surface Preparation Laboratory, Zaandam, The Netherland

Galwey AK, Gray P, Griffiths JF, Hasko SM (1985) Nature 313:668

Derry GN, Ross PN (1984) Surf Sci 140:165

Parker DH, Bartram ME, Koel BE (1989) Surf Sci 217:489

Klikovits J, Schmid M, Merte LR, Varga P, Westerström R, Resta A, Andersen JN, Gustafson J, Mikkelsen A, Lundgren E, Mittendorfer F, Kresse G (2008) Phys Rev Lett 101:266104

Lundgren E et al (2006) J Phys Condens Matter 18:R481

Todorova M, Li WX, Ganduglia-Pirovano MV, Stampfl C, Reuter K, Scheffler M (2002) Phys Rev Lett 89:096103

Bleakley K, Hu P (1999) J Am Chem Soc 121:7644

Li WX, Hammer B (2005) Chem Phys Lett 409:1

Gerrard AL, Weaver JF (2005) J Chem Phys 123:224703

Rotermund HH, Lauterbach J, Haas G (1993) Appl Phys A Mater Sci Process 57:507

Lauterbach J, Asakura K, Rotermund HH (1994) Surf Sci 313:52

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Bashlakov, D.L., Juurlink, L.B.F., Koper, M.T.M. et al. Subsurface Oxygen on Pt(111) and Its Reactivity for CO Oxidation. Catal Lett 142, 1–6 (2012). https://doi.org/10.1007/s10562-011-0730-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-011-0730-z