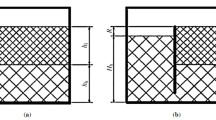

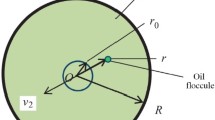

The water-oil emulsion separation process in a gravity-dynamic separator was investigated experimentally in three modes of separator use: without baffles, with baffles in the form of inserts made of open-cell foam material (OCFM), and with plate baffles. An ultrasonic mixer with OCFM baffles was used to produce the emulsion. The results showed the following: in a separator without baffles, separation is less effective; in a separator with OCFM baffles, separation is more effective at low emulsion flow rates; in a separator with plate baffles, separation is more effective at high emulsion flow rates.

Similar content being viewed by others

Change history

22 April 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10556-021-00912-1

References

C. Chapuis, Y. Lacourie, and D. Lancois, “Testing of down hole oil/water separation system in Lacq Superieur field, France,” in: SPE European Formation Damage Conference, Society of Petroleum Engineers (1999), pp. 415-424.

T. Krebs, C. Schroën, and R. M. Boom, “Separation kinetics of an oil-in-water emulsion under enhanced gravity,” Chem. Eng. Sci., 71, 118-125 (2012).

K. Arnold and M. Stewart, Design of Oil-Handling Systems and Facilities, Gulf Professional Publishing, Vol. 1 (1986).

W. Y. Svrcek and W. D. Monnery, “Design of two-phase separators within the right limits,” Chem. Eng. Progress, 89, No. 10, 53–60 (1993).

E. W. M. Hansen and G. J. Rortveit, “Numerical simulation of fluid mechanisms and separation behavior in offshore gravity separators,” Surfact. Sci. Ser., 132, 593–606 (2006).

Russian Federation Patent No. 2013106536/05, Method of Separation of Stable Emulsions and Device for Its Implementation (Variants) [in Russian], claimed by I. Yu. Portnov, A. V. Milchakov, A. P. Zharkovskii, and P. A. Petrushenkov, 14.02.2013, Byul., No. 23.

B. A. Grimes, “Population balance model for batch gravity separation of crude oil and water emulsions. Part I: Model formulation,” J. Dispers. Sci. Technol., 33, No. 4, 578–590 (2012).

J. H. Song, B. E. Jeong, H. J. Kim, and S. S. Gil, Three-Phases Separator Sizing Using Drop Size Distribution, Offshore Technology Conference, 2010.

M. Abdulkadir and V. Hernandez-Perez, “The effect of mixture velocity and droplet diameter on oil-water separator using computational fluid dynamics (CFD),” World Acad. Sci., Eng., Technol., 61, 35–43 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 56, No. 11, pp. 9−11, November, 2020.

Rights and permissions

About this article

Cite this article

Solov’eva, O.V., Solov’ev, S.A., Yafizov, R.R. et al. Influence of Design of Baffles in a Gravity-Dynamic Separator Model on Water-Oil Emulsion Separation Efficiency. Chem Petrol Eng 56, 884–888 (2021). https://doi.org/10.1007/s10556-021-00857-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-021-00857-5