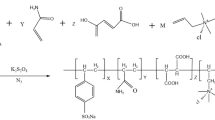

Under ultra-high temperature and high-density conditions, most existing wash isolation liquid suspending agents have limited suspension capabilities at low dosages. This study enhances the suspension ability, optimizes the surface charge distribution, and reduces the probability of precipitation by surface modification and graft polymerization of inorganic mineral materials, thus preparing an organic-inorganic hybrid high-temperature suspension component. By introducing crosslinkers and active monomers with large steric hindrance and high rigidity, the study optimizes the microstructure of the polymer molecular chain, enhances rotational freedom, and improves thermal resistance, leading to the preparation of organic micro-crosslinked ultra-high temperature suspension components. The composite anti- high temperature wash isolation liquid suspending agent prepared in this study combines the characteristics of both inorganic and organic materials. While ensuring rheological properties, it can control the free liquid of the isolation liquid with a density of 2.2 to 2.6 g/cm3 at 200°C to 0 mL, with a density difference of no more than 0.03 g/cm3 after 2 hours of standing, effectively improving the sedimentation stability under high temperature and ultra-high temperature conditions for high-density isolation liquid systems. The results of this study provide a theoretical basis for the safety of deep well cementing operations.

Similar content being viewed by others

Reference

Velayati A., Tokhmechi B., Soltanian H., et al. Cement slurry optimization and assessment of additives according to a proposed plan. Journal of Natural Gas Science and Engineering, 2015, 23, 165-170.

Davoodi S., Al-Shargabi M., Wood D., et al. Recent advances in polymers as additives for wellbore cementing applications: A review. Fuel, 2024, 357, 129692.

Zhang H., Hu M., Xu Y., et al. Inhibitory effects of functionalized polycarboxylate retarder on aberrant thickening phenomena of oil well cement at high temperature. Construction and Building Materials, 2021, 274, 121994.

Ramasamy J., Amanullah M. Nanocellulose for oil and gas field drilling and cementing applications. Journal of Petroleum Science and Engineering, 2020, 184, 106292.

Liu H., Bu Y., Sanjayan J., et al. Suitability of polyacrylamide superabsorbent polymers as the internal curing agent of well cement. Construction and Building Materials, 2016, 112, 253-260.

Khalil M., Amanda A., Yunarti T., et al. Synthesis and application of mesoporous silica nanoparticles as gas migration control additive in oil and gas cement. Journal of Petroleum Science and Engineering, 2020, 195, 107660.

Cao L., Guo J., Tian J., et al. Synthesis, characterization and working mechanism of a novel sustained-release-type fluid loss additive for seawater cement slurry. Journal of Colloid and Interface Science, 2018, 524, 434-444.

Hurnaus T., Plank J. Synthesis, characterization and performance of a novel phosphate-modified fluid loss additive useful in oil well cementing. Journal of Natural Gas Science and Engineering, 2016, 36, 165-174.

Huo M., Liu H., Bu Y. Effect of main functional groups of cement slurry additives on the stability of methane hydrate: Experiment and molecular dynamics simulation. Geoenergy Science and Engineering, 2023, 228, 212024.

Zhang H., Hu M., Li P., et al. Covalently bonded AMPS-based copolymerCSH hybrid as a fluid loss additive for oilwell saline cement slurry in UHT environment. Construction and Building Materials, 2023, 378, 131177.

Ma J., Shu X., Zheng S., et al. Effects of polyurethane–silica nanohybrids as additives on the mechanical performance enhancement of ordinary Portland cement paste. Construction and Building Materials, 2022, 338, 127666.

Mohamadian N., Ramhormozi Z., Wood D., et al. Reinforcement of oil and gas wellbore cements with a methyl methacrylate/carbon-nanotube polymer nanocomposite additive. Cement and Concrete Composites, 2020, 114, 103763.

Wolterbeek T., Cornelissen K., Hangx S., et al. Impact of downhole pressure and fluid-access on the effectiveness of wellbore cement expansion additives. Cement and Concrete Research, 2021, 147, 106514.

Feng Q., Li X., Peng Z., et al. Synthesis and performance evaluation of polycarboxylate dispersant for oil well cement. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 662, 131007.

Bu Y., Lu Z., Lu C., et al. Molecular design and evaluation of hydrate dissociation inhibitors used in cementing slurry based on molecular dynamic simulations. Fuel, 2023, 354, 129317.

Yu Y., Zhang C., Gu T., et al. Synthesis and evaluation of a new type of oil-well cement temperature-resistant retarder. Construction and Building Materials, 2021, 302, 124153.

Kumar S., Bera A., Shah S. Potential applications of nanomaterials in oil and gas well cementing: Current status, challenges and prospects. Journal of Petroleum Science and Engineering, 2022, 213, 110395.

Chen D., Guo J., Xu Y., et al. Adsorption behavior and mechanism of a copolymer used as fluid loss additive in oil well cement. Construction and Building Materials, 2019, 198, 650-661.

Cestari A., Vieira E., Silva E., et al. Synthesis, characterization and hydration analysis of a novel epoxy/superplasticizer oilwell cement slurry – Some mechanistic features by solution microcalorimetry. Journal of Colloid and Interface Science, 2013. 392, 359-368.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 2, pp. 146–151, March– April, 2024.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, B., Zhang, J., Wang, J. et al. Study on the Synthesis and Performance Evaluation of a Composite High-Temperature Flushing Isolation Fluid Stabilizer. Chem Technol Fuels Oils 60, 420–429 (2024). https://doi.org/10.1007/s10553-024-01696-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-024-01696-9