Abstract

Grating-based x-ray dark-field imaging was used to visualize tape edges of chopped carbon fiber tape reinforced thermoplastic (CTT) laminates. Because resin accumulates at the tape edges, a portion where the tape edges in the CTT laminates are dense particularly tends to cause deterioration in mechanical properties. CT measurements using an x-ray grating interferometer and in-plane tensile tests were performed for several CTT laminates to investigate the relation between spatial distributions of the tape edges and mechanical properties of the laminates. Compared with strain distributions obtained using digital image correlation analysis or fractured position, it was indicated the possibility that not only the fiber orientation but also the edge density affected the stiffness and strength of CTT laminates. In addition, the edge densities were also highly correlated with the maximum tensile stress at failure, with the correlation coefficient of −0.87. These findings suggest that fiber orientation and edge density are important elements in explaining the stiffness and strength of CTT laminates.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Wan, Y., Takahashi, J.: Tensile and compressive properties of chopped carbon fiber tapes reinforced thermoplastics with different fiber lengths and molding pressures. Compos. A: Appl. Sci. Manuf 87, 271–281 (2016). https://doi.org/10.1016/j.compositesa.2016.05.005

Matsuo, T., Kan, M., Furukawa, K., Sumiyama, T., Enomoto, H., Sakaguchi, K.: Numerical modeling and analysis for axial compressive crushing of randomly oriented thermoplastic composite tubes based on the out-of-plane damage mechanism. Compos. Struct 181, 368–378 (2017). https://doi.org/10.1016/j.compstruct.2017.08.104

Vaidya, U.K., Chawla, K.K.: Processing of fibre reinforced thermoplastic composites. Int. Mater. Rev 53, 185–218 (2008). https://doi.org/10.1179/174328008X325223

Feraboli, P., Peitso, E., Deleo, F., Cleveland, T., Stickler, P.B.: Characterization of prepreg-based discontinuous carbon fiber/epoxy systems. J. Reinf Plast. Compos 28, 1191–1214 (2009). https://doi.org/10.1177/0731684408088883

Selezneva, M., Lessard, L.: Characterization of mechanical properties of randomly oriented strand thermoplastic composites. J. Compos. Mater 50, 2833–2851 (2016). https://doi.org/10.1177/0021998315613129

Feraboli, P., Cleveland, T., Ciccu, M., Stickler, P., DeOto, L.: Defect and damage analysis of advanced discontinuous carbon/epoxy composite materials. Compos. A: Appl. Sci. Manuf 4, 888–901 (2010). https://doi.org/10.1016/j.compositesa.2010.03.002

Selezneva, M., Roy, S., Lessard, L., Yousefpour, A.: Analytical model for prediction of strength and fracture paths characteristic to randomly oriented strand (ROS) composites. Compos. B: Eng 96, 103–111 (2016). https://doi.org/10.1016/j.compositesb.2016.04.017

Selezneva, M., Roy, S., Meldrum, S., Lessard, L., Yousefpour, A.: Modelling of mechanical properties of randomly oriented strand thermoplastic composites. J. Compos. Mater 51, 831–845 (2017). https://doi.org/10.1177/0021998316654748

Pfeiffer, F., Weitkamp, T., Bunk, O., David, C.: Phase retrieval and differential phase-contrast imaging with low-brilliance X-ray sources. Nat. Phys 2, 258–261 (2006). https://doi.org/10.1038/nphys265

Pfeiffer, F., Bech, M., Bunk, O., Kraft, P., Eikenberry, E.F., Brönnimann, C., Grünzweig, C., David, C.: Hard-X-ray dark-field imaging using a grating interferometer. Nat. Mater 7, 134–137 (2008). https://doi.org/10.1038/nmat2096

Prade, F., Schaff, F., Senck, S., Meyer, P., Mohr, J., Kastner, J., Pfeiffer, F.: Nondestructive characterization of fiber orientation in short fiber reinforced polymer composites with X-ray vector radiography. NDT & E Int 86, 65–72 (2017). https://doi.org/10.1016/j.ndteint.2016.11.013

Senck, S., Scheerer, M., Revol, V., Plank, B., Hannesschläger, C., Gusenbauer, C., Kastner, J.: Microcrack characterization in loaded CFRP laminates using quantitative two-and three-dimensional X-ray dark-field imaging. Compos. A: Appl. Sci. Manuf 115, 206–214 (2018). https://doi.org/10.1016/j.compositesa.2018.09.023

Murakami, T., Matsuo, T., Sumiyama, T.: Experimental method and evaluation for interlaminar shear properties of randomly oriented strand thermoplastic composites based on modified double-notch specimen and two dimensional digital image correlation. J. Compos. Mater 55, 1315–1330 (2021). https://doi.org/10.1177/0021998320967719

Johanson, K., Harper, L.T., Johnson, M.S., Warrior, N.A.: Heterogeneity of discontinuous carbon fibre composites: Damage initiation captured by digital image correlation. Compos. A: Appl. Sci. Manuf 68, 304–312 (2015). https://doi.org/10.1016/j.compositesa.2014.10.014

Feraboli, P., Peitso, E., Cleveland, T., Stickler, P.B.: Modulus measurement for prepreg-based discontinuous carbon fiber/epoxy systems. J. Compos. Mater 43, 1947–1965 (2009). https://doi.org/10.1177/0021998309343028

EN ISO 527-4: Plastics - Determination of tensile properties - Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites,” International Organization for Standardization (ISO), Geneva, Switzerland (2021)

Shirai, T., Sakaguchi, M., Uzawa, K., Doki, T., Morimoto, N., Kimura, K., Koh, S.: Analysis of Fiber orientation and a Simulation of damage fracture prediction using an X-ray phase imaging method for discontinuous Carbon Fiber Random laminated Molded Products. J. Jpn Soc. Compos. Mater. 48, 41–51 (2022). https://doi.org/10.6089/jscm.48.41. (in Japanese)

Sumiyama, T., Matsuo, T., Kan, M., Furuichi, K., Nonomura, C.: Non-linear finite element analysis for three-point bending behavior of randomly-oriented thermoplastic CFRP. J. Jpn Soc. Compos. Mater. 43, 149–159 (2017). https://doi.org/10.6089/jscm.43.149. (in Japanese)

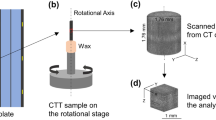

Morimoto, N., Kimura, K., Shirai, T., Doki, T., Sano, S., Horiba, A., Kitamura, K.: Talbot–Lau interferometry-based x-ray imaging system with retractable and rotatable gratings for nondestructive testing. Rev. Sci. Instrum 91, 023706 (2020). https://doi.org/10.1063/1.5131306

Morimoto, N., Kimura, K., Shirai, T., Doki, T.: US Patent Application No 16, 885524 (2021)

Rasband, W.S., ImageJ, U.S.: National Institutes of Health, Bethesda, Maryland, USA, http://imagej.nih.gov/ij/

Wagner, T., Hiner, M., Raynaud, X.: Thorstenwagner/Ij-Ridgedetection: Ridge Detection 1.4.0. Zenodo. (2017). https://doi.org/10.5281/ZENODO.845874

Tsai, S.W., Hahn, H.T.: Introduction to composite materials. Technomic Publishing (1980)

Revol, V., Kottler, C., Kaufmann, R., Neels, A., Dommann, A.: Orientation-selective X-ray dark field imaging of ordered systems. J. Appl. Phys 112, 114903 (2012). https://doi.org/10.1063/1.4768525

Schaff, F., Malecki, A., Potdevin, G., Eggl, E., Noël, P.B., Baum, T., Garcia, E.G., Bauer, J.S., Pfeiffer, F.: Correlation of x-ray vector radiography to bone micro-architecture. Sci. Rep 4, 3695 (2014). https://doi.org/10.1038/srep03695

Non-contacting video extensometer: (Ave2), Instron. https://www.instron.com/en/products/testing-accessories/extensometers/non-contacting-video. Accessed 23 March 2023

Acknowledgments

This study was realized in collaboration with National Maritime Research Institute, Japan, Toyobo Co. LTD, Toray Co. LTD. We would like to thank Dr. T. Shirai of Kanazawa Institute of Technology for preparing the CTT laminate of Sample A.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Morimoto, N., Matsuo, T., Sumiyama, T. et al. Evaluation of Effect of Tape Edges on Tensile Properties of Chopped Carbon Fiber Tape Reinforced Thermoplastics by X-ray Grating Interferometry. Appl Compos Mater 30, 1587–1603 (2023). https://doi.org/10.1007/s10443-023-10139-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-023-10139-3