Abstract

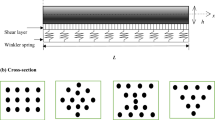

Fiber reinforced composite lattice sandwich structures are lightweight attractive for their excellent mechanical properties. It is an ideal option for the bulkhead of the superstructure of a ship. In this paper, a new sandwich panel with an orthogonal corrugate lattice core was investigated experimentally, theoretically, and numerically. Its flatwise compression properties were tested. And the influence of the geometry of the lattice core was discussed. The results showed that local matrix compression damage and delamination caused by compression at the rib corner were an initial failure in compression. The final failure was rib fracture in the experiment. Simulated and predicted modulus matched the experiment well with relative errors of 14.61% and 10.03%, respectively. The compressive strength in the simulation was 2.86% higher than that in the experiment. Compression properties were linearly dependent on the relative density of the lattice core. The compressive modulus and strength were most sensitive to the radius of arc transition at the rib corner.

Similar content being viewed by others

Data Availability Statement

All data generated or analysed during this study are included in this article.

References

Liu, H., Chen, L., Du, B., Peng, S., Guo, Y., Zhao, Y., et al.: Flatwise compression property of hierarchical thermoplastic composite square lattice. Compos. Struct. 210, 118–133 (2019). https://doi.org/10.1016/j.compstruct.2018.11.047

Wu, Q., Vaziri, A., Asl, M.E., Ghosh, R., Gao, Y., Wei, X., et al.: Lattice materials with pyramidal hierarchy: Systematic analysis and three dimensional failure mechanism maps. J. Mech. Phys. Solids 125, 112–144 (2019). https://doi.org/10.1016/j.jmps.2018.12.006

Haldar, A.K., Guan, Z.W., Cantwell, W.J., Wang, QY.: The compressive properties of sandwich structures based on an egg-box core design. Compos. Part B Eng. 144, 143–152 (2018). https://doi.org/10.1016/j.compositesb.2018.03.007

Morshedsoluk, F., Khedmati, MR.: Ultimate strength of composite ships’ hull girders in the presence of composite superstructures. Thin Wall Struct. 102, 122–138 (2016). https://doi.org/10.1016/j.tws.2016.01.024

Gargano, A., Pingkarawat, K., Blacklock, M., Pickerd, V., Mouritz, A.P.: Comparative assessment of the explosive blast performance of carbon and glass fibre-polymer composites used in naval ship structures. Compos. Struct. 171, 306–316 (2017). https://doi.org/10.1016/j.compstruct.2017.03.041

Vitale, J.P., Francucci, G., Xiong, J., Stocchi, A.: Failure mode maps of natural and synthetic fiber reinforced composite sandwich panels. Compos. A: Appl. Sci. Manuf. 94, 217–225 (2017). https://doi.org/10.1016/j.compositesa.2016.12.021

Zheng, T., Yan, H., Li, S., Cheng, Y., Zou, L., Hu, Y.: Compressive behavior and failure modes of the wood-based double X-type lattice sandwich structure. Journal of Building Engineering 30, 101176 (2020). https://doi.org/10.1016/j.jobe.2020.101176

Azzouz, L., Chen, Y., Zarrelli, M., Pearce, J. M., Mitchell, L., Ren, G., et al.: Mechanical properties of 3-D printed truss-like lattice biopolymer non-stochastic structures for sandwich panels with natural fibre composite skins. Compos. Struct. 213, 220–230 (2019). https://doi.org/10.1016/j.compstruct.2019.01.103

Liu, J., Li, C., Deng, S., Liu, J., Huang, W.: The edgewise compressive behavior and failure mechanism of the composite Y-frame core sandwich column. Polym. Test. 81, 106188 (2020). https://doi.org/10.1016/j.polymertesting.2019.106188

Liu, J., Zhang, T., Jiang, W., Liu, J.: Mechanical response of a novel composite Y-frame core sandwich panel under shear loading. Compos. Struct. 224, 111064 (2019). https://doi.org/10.1016/j.compstruct.2019.111064

Liu, J., He, Z., Liu, J., Huang, W.: Bending response and failure mechanism of composite sandwich panel with Y-frame core. Thin Wall Struct 145, 106387 (2019). https://doi.org/10.1016/j.tws.2019.106387

Smardzewski, J., Wojciechowski, K.W.: Response of wood-based sandwich beams with three-dimensional lattice core. Compos. Struct. 216, 340–349 (2019). https://doi.org/10.1016/j.compstruct.2019.03.009

Velea, M.N., Schneider, C., Lache, S.: Second order hierarchical sandwich structure made of self-reinforced polymers by means of a continuous folding process. Mater. Des. 102, 313–320 (2016). https://doi.org/10.1016/j.matdes.2016.04.049

Xiong, J., Ma, L., Pan, S., Wu, L., Papadopoulos, J., Vaziri, A.: Shear and bending performance of carbon fiber composite sandwich panels with pyramidal truss cores. Acta Mater. 60(4), 1455–1466 (2012). https://doi.org/10.1016/j.actamat.2011.11.028

Zhang, G., Ma, L., Wang, B., Wu, L.: Mechanical behaviour of CFRP sandwich structures with tetrahedral lattice truss cores. Compos. Part B Eng. 43(2), 471–476 (2012). https://doi.org/10.1016/j.compositesb.2011.11.017

Zhang, X., Chen, J., Okabe, Y., Zhang, P., Xiong, X., Yu, X.: Influence of honeycomb dimensions and forming methods on the compressive properties of beetle elytron plates. J. Sandw. Struct. Mater. 22(1), 28–39 (2020). https://doi.org/10.1177/1099636217731993

Chen, J., Zhang, X., Okabe, Y., Xie, J., Xu, M.: Beetle elytron plate and the synergistic mechanism of a trabecular-honeycomb core structure. Sci. China Technol. Sci. 62(1), 87–93 (2019). https://doi.org/10.1007/s11431-018-9290-1

Codyre, L., Mak, K., Fam, A.: Flexural and axial behaviour of sandwich panels with bio-based flax fibre-reinforced polymer skins and various foam core densities. J. Sandw. Struct. Mater. 20(5), 595–616 (2018). https://doi.org/10.1177/1099636216667658

Hu, Y., Li, W., An, X., Fan, H.: Fabrication and mechanical behaviors of corrugated lattice truss composite sandwich panels. Compos. Sci. Technol. 125, 114–122 (2016). https://doi.org/10.1016/j.compscitech.2016.02.003

Sharaf, T., Fam, A.: Experimental investigation of large-scale cladding sandwich panels under out-of-plane transverse loading for building applications. J. Compos. Constr. 15(3), 422–430 (2011). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000176

Alfouneh, M., Ji, J., Luo, Q.: Optimal design of multi-cellular cores for sandwich panels under harmonic excitation. Compos. Struct. 248, 112507 (2020). https://doi.org/10.1016/j.compstruct.2020.112507

Huo, X., Liu, H., Luo, Q., Sun, G., Li, Q.: On low-velocity impact response of foam-core sandwich panels. Int. J. Mech. Sci. 181, 105681 (2020). https://doi.org/10.1016/j.ijmecsci.2020.105681

Zhang, X., Yu, X., Chen, J., Pan, L., Hu, L., Fu, Y.: Vibration properties and transverse shear characteristics of multibody molded beetle elytron plates. Sci. China Technol. Sci. 63(12), 2584 (2020). https://doi.org/10.1007/s11431-019-1570-6

Cheng, Y., Zhou, T., Wang, H., Li, Y., Liu, J., Zhang, P.: Numerical investigation on the dynamic response of foam-filled corrugated core sandwich panels subjected to air blast loading. J. Sandw. Struct. Mater. 21(3), 838–864 (2019). https://doi.org/10.1177/1099636217700350

Ha, N. S., Lu, G., Xiang, X.: Energy absorption of a bio-inspired honeycomb sandwich panel. J. Mater. Sci. 54(8), 6286–6300 (2019). https://doi.org/10.1007/s10853-018-3163-x

Zamanifar, H., Sarrami-Foroushani, S., Azhari, M.: Static and dynamic analysis of corrugated-core sandwich plates using finite strip method. Eng. Struct. 183, 30–51 (2019). https://doi.org/10.1016/j.engstruct.2018.12.102

Arunkumar, M. P., Pitchaimani, J., Gangadharan, K. V.: Bending and free vibration analysis of foam-filled truss core sandwich panel. J. Sandw. Struct. Mater. 20(5), 617–638 (2018). https://doi.org/10.1177/1099636216670612

Shunmugasamy, V. C., Mansoor, B.: Aluminum foam sandwich with density-graded open-cell core: Compressive and flexural response. Mater. Sci. Eng. A 731, 220–230 (2018). https://doi.org/10.1016/j.msea.2018.06.048

Rong, Y., Liu, J., Luo, W., He, W.: Effects of geometric configurations of corrugated cores on the local impact and planar compression of sandwich panels. Compos. Part B Eng. 152, 324–335 (2018). https://doi.org/10.1016/j.compositesb.2018.08.130

Ferdous, W., Manalo, A., Aravinthan, T., Fam, A.: Flexural and shear behaviour of layered sandwich beams. Constr. Build. Mater. 173, 429–442 (2018). https://doi.org/10.1016/j.conbuildmat.2018.04.068

Li, W., Sun, F., Wang, P., Fan, H., Fang, D.: A novel carbon fiber reinforced lattice truss sandwich cylinder: Fabrication and experiments. Compos. A: Appl. Sci. Manuf. 81, 313–322 (2016). https://doi.org/10.1016/j.compositesa.2015.11.034

Hundley, J.M., Clough, E.C., Jacobsen, A.J.: The low velocity impact response of sandwich panels with lattice core reinforcement. Int. J. Impact. Eng. 84, 64–77 (2015). https://doi.org/10.1016/j.ijimpeng.2015.05.009

Mathieson, H., Fam, A.: High cycle fatigue under reversed bending of sandwich panels with GFRP skins and polyurethane foam core. Compos. Struct. 113, 31–39 (2014). https://doi.org/10.1016/j.compstruct.2014.02.027

Liu, Y., Zhou, C., Cen, B., Zeng, Z., Lu, X., Zhu, X.: Compression property of a novel lattice sandwich structure. Compos. Part B Eng. 117, 130–137 (2017). https://doi.org/10.1016/j.compositesb.2017.02.036

Hashin, Z.: Failure Criteria for Unidirectional Fiber Composites. J. Appl. Mech. 47(2), 329–334 (1980)

Chang, F.K., Chang, K.Y.: A progressive damage model for laminated composites containing stress concentrations. J Compos Mater 21(3), 409–416 (1987)

Russell, B., Deshpande, V., Wadley, H.: Quasistatic deformation and failure modes of composite square honeycombs. J. Mech. Mater. Struct. 3(7), 1315–1340 (2008). https://doi.org/10.2140/jomms.2008.3.1315

Acknowledgements

Financial supports from the National Natural Science Foundations of China (No. 11772147), the Natural Science Foundation of Jiangsu Province, China (No. BK20200706), the Major University Science Research Project of Jiangsu Province, China (No. 20KJA460001), and The National Key Scientific Research Instrument and Equipment Development Project (Major Program, No. 12027901) were gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Li, M., Li, Q. et al. Influence of Geometric Parameters on Flatwise Compression Properties of a Novel Lattice Sandwich. Appl Compos Mater 28, 1589–1608 (2021). https://doi.org/10.1007/s10443-021-09918-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09918-7