Abstract

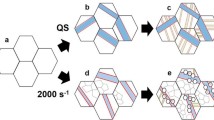

As an attractive class of metallic materials, single-phase CrCoNi medium-entropy alloy (MEA) has drawn much attention recently regarding their deformation behaviors, but the dynamically mechanical responses of this alloy at high strain rates remain less studied, especially coupled with extremely low temperatures. In this study, the dynamic deformation behaviors of this CrCoNi MEA were systematically investigated at room temperature (RT) of 298 K and liquid nitrogen temperature (LNT) of 77 K using the split Hopkinson pressure bar (SHPB). This alloy exhibited a combination of higher yield strength and stronger hardening rate upon dynamic compressive deformation when the loading conditions become much harsher (higher strain rate or lower temperature). Detailed microstructure analyses indicated that the strong strain hardening ability during dynamic deformation was mainly attributed to the continuous formation of nanoscale deformation twins. Furthermore, as loaded at LNT, multi-directional deformation twins were activated. Meanwhile, due to the interaction between Shockley partial dislocations and twin boundaries, large-sized deformation-induced FCC-HCP phase transformations at a micrometer scale were also observed within the grains, which not only accommodated the plasticity but also played an important role in improving the hardening capability owing to the appearance of newly generated interfaces.

摘要

作为一种极具吸引力的金属材料, 单相CrCoNi中熵合金(medium-entropy alloy, MEA)的变形行为最近引起了广泛的关注, 但该合金在高应变率, 尤其是高应变率低温耦合条件下的力学响应目前仍然鲜有报道. 本研究使用分离式霍普金森压杆系统地研究了CrCoNi MEA在室温(room temperature, RT)和液氮温度(liquid nitrogen temperature, LNT)下的动态变形行为. 随着应变率升高或温度的降低, 该合金在动态压缩时表现出更高的屈服强度(yield strength, YS)和应变硬化率. 详细的微观结构表征发现, 动态变形过程中较强的应变硬化能力主要归因于纳米级变形孪晶的连续形成. 此外, 当加载温度降低到LNT时, 多取向变形孪晶被激活. 同时, 由于肖克莱不全位错与孪晶界的相互作用, 在晶粒内也观察到了大尺寸的变形诱导的FCC-HCP相变, 这不仅容纳了塑性, 新形成的界面还会提高合金的应变硬化能力.

Similar content being viewed by others

References

Y. F. Ye, Q. Wang, J. Lu, C. T. Liu, and Y. Yang, High-entropy alloy: challenges and prospects, Mater. Today 19, 349 (2016).

D. B. Miracle, High entropy alloys as a bold step forward in alloy development, Nat. Commun. 10, 1805 (2019).

E. P. George, D. Raabe, and R. O. Ritchie, High-entropy alloys, Nat. Rev. Mater. 4, 515 (2019).

D. B. Miracle, and O. N. Senkov, A critical review of high entropy alloys and related concepts, Acta Mater. 122, 448 (2017).

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, and P. K. Liaw, Mechanical behavior of high-entropy alloys, Prog. Mater. Sci. 118, 100777 (2021).

Z. Li, S. Zhao, R. O. Ritchie, and M. A. Meyers, Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys, Prog. Mater. Sci. 102, 296 (2019).

Y. Zhang, T. T. Zuo, Z. Tang, M. C. Gao, K. A. Dahmen, P. K. Liaw, and Z. P. Lu, Microstructures and properties of high-entropy alloys, Prog. Mater. Sci. 61, 1 (2014).

B. Gludovatz, A. Hohenwarter, K. V. S. Thurston, H. Bei, Z. Wu, E. P. George, and R. O. Ritchie, Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures, Nat. Commun. 7, 10602 (2016).

B. Gludovatz, A. Hohenwarter, D. Catoor, E. H. Chang, E. P. George, and R. O. Ritchie, A fracture-resistant high-entropy alloy for cryogenic applications, Science 345, 1153 (2014).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E. P. George, The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy, Acta Mater. 61, 5743 (2013).

X. D. Xu, P. Liu, Z. Tang, A. Hirata, S. X. Song, T. G. Nieh, P. K. Liaw, C. T. Liu, and M. W. Chen, Transmission electron microscopy characterization of dislocation structure in a face-centered cubic high-entropy alloy Al0.1CoCrFeNi, Acta Mater. 144, 107 (2018).

S. F. Liu, Y. Wu, H. T. Wang, J. Y. He, J. B. Liu, C. X. Chen, X. J. Liu, H. Wang, and Z. P. Lu, Stacking fault energy of face-centered-cubic high entropy alloys, Intermetallics 93, 269 (2018).

I. Gutierrez-Urrutia, and D. Raabe, Dislocation and twin substructure evolution during strain hardening of an Fe-22wt.%Mn-0.6wt.%C TWIP steel observed by electron channeling contrast imaging, Acta Mater. 59, 6449 (2011).

Y. F. Shen, N. Jia, R. D. K. Misra, and L. Zuo, Softening behavior by excessive twinning and adiabatic heating at high strain rate in a Fe-20Mn-0.6C TWIP steel, Acta Mater. 103, 229 (2016).

T. W. Zhang, S. G. Ma, D. Zhao, Y. C. Wu, Y. Zhang, Z. H. Wang, and J. W. Qiao, Simultaneous enhancement of strength and ductility in a NiCoCrFe high-entropy alloy upon dynamic tension: micro-mechanism and constitutive modeling, Int. J. Plast. 124, 226 (2020).

R. Sonkusare, R. Jain, K. Biswas, V. Parameswaran, and N. P. Gurao, High strain rate compression behaviour of single phase CoCuFeMnNi high entropy alloy, J. Alloys Compd. 823, 153763 (2020).

N. Kumar, Q. Ying, X. Nie, R. S. Mishra, Z. Tang, P. K. Liaw, R. E. Brennan, K. J. Doherty, and K. C. Cho, High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy, Mater. Des. 86, 598 (2015).

K. Jiang, T. Ren, G. Shan, T. Ye, L. Chen, C. Wang, F. Zhao, J. Li, and T. Suo, Dynamic mechanical responses of the Al0.1CoCrFeNi high entropy alloy at cryogenic temperature, Mater. Sci. Eng.-A 797, 140125 (2020).

J. M. Park, J. Moon, J. W. Bae, M. J. Jang, J. Park, S. Lee, and H. S. Kim, Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy, Mater. Sci. Eng.-A 719, 155 (2018).

Z. Li, S. Zhao, H. Diao, P. K. Liaw, and M. A. Meyers, High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: remarkable resistance to shear failure, Sci. Rep. 7, 42742 (2017).

J. He, Q. Wang, H. Zhang, L. Dai, T. Mukai, Y. Wu, X. Liu, H. Wang, T. G. Nieh, and Z. Lu, Dynamic deformation behavior of a face-centered cubic FeCoNiCrMn high-entropy alloy, Sci. Bull. 63, 362 (2018).

Z. Li, S. Zhao, S. M. Alotaibi, Y. Liu, B. Wang, and M. A. Meyers, Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy, Acta Mater. 151, 424 (2018).

Y. Ma, F. Yuan, M. Yang, P. Jiang, E. Ma, and X. Wu, Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures, Acta Mater. 148, 407 (2018).

B. Gan, J. M. Wheeler, Z. Bi, L. Liu, J. Zhang, and H. Fu, Superb cryogenic strength of equiatomic CrCoNi derived from gradient hierarchical microstructure, J. Mater. Sci. Tech. 35, 957 (2019).

J. Moon, S. I. Hong, J. W. Bae, M. J. Jang, D. Yim, and H. S. Kim, On the strain rate-dependent deformation mechanism of CoCrFeMnNi high-entropy alloy at liquid nitrogen temperature, Mater. Res. Lett. 5, 472 (2017).

Z. Liu, Y. Yu, Z. Yang, Y. Wei, J. Cai, M. Li, and C. Huang, Dynamic experimental studies of A6N01S-T5 aluminum alloy material and structure for high-speed trains, Acta Mech. Sin. 35, 763 (2019).

M. A. Meyers, Dynamic behavior of materials (John Wiley & Sons, New York, 1994).

Y. Deng, C. C. Tasan, K. G. Pradeep, H. Springer, A. Kostka, and D. Raabe, Design of a twinning-induced plasticity high entropy alloy, Acta Mater. 94, 124 (2015).

G. Laplanche, A. Kostka, O. M. Horst, G. Eggeler, and E. P. George, Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy, Acta Mater. 118, 152 (2016).

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E. P. George, Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi, Acta Mater. 128, 292 (2017).

J. Miao, C. E. Slone, T. M. Smith, C. Niu, H. Bei, M. Ghazisaeidi, G. M. Pharr, and M. J. Mills, The evolution of the deformation substructure in a Ni-Co-Cr equiatomic solid solution alloy, Acta Mater. 132, 35 (2017).

K. Jiang, B. Gan, J. Li, Q. Dou, and T. Suo, Towards strength-ductility synergy in a CrCoNi solid solution alloy via nanotwins, Mater. Sci. Eng.-A 816, 141298 (2021).

Y. Ateba Betanda, A. L. Helbert, F. Brisset, M. H. Mathon, T. Waeckerlé, and T. Baudin, Measurement of stored energy in Fe-48%Ni alloys strongly cold-rolled using three approaches: neutron diffraction, Dillamore and KAM approaches, Mater. Sci. Eng.-A 614, 193 (2014).

Y. Qiao, Y. Chen, F. H. Cao, H. Y. Wang, and L. H. Dai, Dynamic behavior of CrMnFeCoNi high-entropy alloy in impact tension, Int. J. Impact Eng. 158, 104008 (2021).

B. C. De Cooman, Y. Estrin, and S. K. Kim, Twinning-induced plasticity (TWIP) steels, Acta Mater. 142, 283 (2018).

Y. H. Jo, S. Jung, W. M. Choi, S. S. Sohn, H. S. Kim, B. J. Lee, N. J. Kim, and S. Lee, Cryogenic strength improvement by utilizing room-temperature deformation twinning in a partially re-crystallized VCrMnFeCoNi high-entropy alloy, Nat. Commun. 8, 15719 (2017).

M. A. Meyers, O. Vöhringer, and V. A. Lubarda, The onset of twinning in metals: a constitutive description, Acta Mater. 49, 4025 (2001).

N. L. Okamoto, S. Fujimoto, Y. Kambara, M. Kawamura, Z. M. T. Chen, H. Matsunoshita, K. Tanaka, H. Inui, and E. P. George, Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy, Sci. Rep. 6, 35863 (2016).

C. Niu, C. R. LaRosa, J. Miao, M. J. Mills, and M. Ghazisaeidi, Magnetically-driven phase transformation strengthening in high entropy alloys, Nat. Commun. 9, 1363 (2018).

C. E. Slone, S. Chakraborty, J. Miao, E. P. George, M. J. Mills, and S. R. Niezgoda, Influence of deformation induced nanoscale twinning and FCC-HCP transformation on hardening and texture development in medium-entropy CrCoNi alloy, Acta Mater. 158, 38 (2018).

T. Ye, F. Zhao, L. Chen, K. Jiang, Q. Deng, Y. Chen, Q. Wang, and T. Suo, Effect of strain rate and low temperature on mechanical behaviour and microstructure evolution in twinning-induced plasticity steel, Mater. Sci. Eng.-A 823, 141734 (2021).

K. Wang, D. Wang, and F. Han, Effect of crystalline grain structures on the mechanical properties of twinning-induced plasticity steel, Acta Mech. Sin. 32, 181 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 12102363), and the China National Funds for Distinguished Young Scientists (Grant No. 12025205).

Rights and permissions

About this article

Cite this article

Jiang, K., Li, J., Gan, B. et al. Dynamically compressive behaviors and plastic mechanisms of a CrCoNi medium entropy alloy at various temperatures. Acta Mech. Sin. 38, 421550 (2022). https://doi.org/10.1007/s10409-022-09003-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-022-09003-w