Abstract

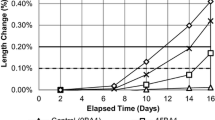

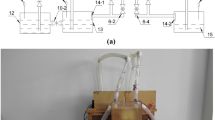

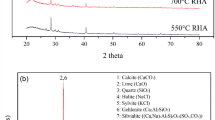

This study reports the effects of the volume fraction of natural jute fiber and the content of the alkali activator on the physical and mechanical properties, sulfate ion resistance, and water purification characteristics of non-cement porous vegetation blocks. The volume fractions of the natural jute fiber were 0.0, 0.1, and 0.2 %, and the alkali activator was applied by replacing 5, 6, 7, 8, 9, and 10 % by weight of the blast-furnace slag. Void ratio, compressive strength, sulfate resistance, and water purification characteristics were characterized. The results indicate that increasing natural jute fiber and the alkali activator content increased the void ratio and improved compressive strength and sulfate resistance. pH was not affected by natural jute fiber content but increased with alkali activator content. At alkali activator contents of 9–10 %, the observed compressive strength was similar to that of cement blocks, whereas mixes with alkali activator contents of 8–10 % showed similar or greater void ratios than those of cement blocks. The compressive strength of the cement blocks decreased following immersion in sulfate solutions; however, the compressive strength of the mixes with the alkali activator and blast-furnace slag increased following exposure to sulfates. Water purification characteristics were examined by allowing water to filter through the blocks; the non-cement porous vegetation blocks reduced the suspended solids, 5-day biological oxygen demand, chemical oxygen demand, total nitrogen, and total phosphorous in the water by >40 %.

Similar content being viewed by others

References

Bentur A, Mindess S, Vondran G (1989) Bonding in polypropylene fibre reinforced concrete. Int J Cem Compos Lightweight Concr 11(3):153–158

APHA (1998) Standard methods for the examination of water and wastewater, 18th edn. American Public Health Association, Washington, DC

Özodabaş A, Yılmaz K (2013) Improvement of the performance of alkali activated blast furnace slag mortars with very finely ground pumice. Constr Build Mater 48:26–34

Lian C, Zhuge Y, Beecham S (2011) The relationship between porosity and strength for porous concrete. Constr Build Mater 25(11):4294–4298

Sung CY (2006) Freezing and thawing properties of polypropylene fiber reinforced eco-concrete. J Korean Soc Agric Eng 48(2):59–66

Sung CY, Kim YI (2010) Void ratio and strength of porous polymer concrete and initial growth properties within planting block with binder contents. J Korean Soc Agric Eng 52(6):101–110

Kim DH, Kim CS, Park CG (2013) Physical and mechanical properties of non-cement porous concrete with alkali-activator contents. J Korean Soc Agric Eng 55(2):59–64

Gruyaert E, Van den Heede P, Maes M, De Belie N (2012) Investigation of the influence of blast-furnace slag on the resistance of concrete against organic acid or sulphate attack by means of accelerated degradation tests. Cem Concr Res 42(1):173–185

Chen F, Xu Y, Wang C, Mao J (2013) Effects of concrete content on seed germination and seedling establishment in vegetation concrete matrix in slope restoration. Ecol Eng 58:99–104

Kim HH, Kang SM, Park JS, Park SW, Jeon JH, Lee JH, Cha SS, Park CG (2010) Effect of blast furnace slag, hwang-toh and reinforcing fibers on the physical and mechanical properties of porous concrete using blast furnace slag coarse aggregate. J Korean Soc Agric Eng 57(3):9–17

Lee JH, Park CG, Park JS (2011) Effect of reinforcing fiber on mechanical properties and chemical resistance of porous concrete with hwang-toh. J Korean Soc Civil Eng 31(2):105–113

Yang KH, Hwang HZ, Kim SY, Song JK (2006) Effect of superplasticizers and admixtures on the fluidity and compressive strength development of cementless mortar using hwangtoh binder. J Korea Concr Inst 18(6):793–800

Yang KH, Oh SJ, Song JK (2008) Mechanical properties of alkali-activated slag-based concrete using lightweight aggregates. J Korea Concr Inst 20(3):405–412

KS M0011 (2008) Standard method for determination of pH of aqueous solutions. Korean Industrial Standards, Republic of Korea

Karim MR, Zain MFM, Jamil M, Lai FC (2013) Fabrication of a non-cement binder using slag, palm oil fuel ash and rice husk ash with sodium hydroxide. Constr Build Mater 49:894–902

Oh RO, Kim CS, Kim HH, Jeon JH, Kwon WS, Park CG (2013) Physical mechanical and temperature properties of fiber reinforced porous green roof hwang-toh concrete. J Korean Soc Agric Eng 55(2):59–64

Park SB, Lee BJ, Lee J, Jang YI (2010) A study on the seawater purification characteristics of water-permeable concrete using recycled aggregate. Resour Conserv Recycl 54(10):658–665

Wen-jie S, Hong-yuan F, Gui-yao W (2008) Cement paste characteristics and porous concrete properties. Constr Build Mater 22(5):894–901

Wen-jie S, Hong-yuana F, Gui-yao W (2012) Study on a kind of eco-concrete retaining wall’s block with water purification function. Procedia Eng 28:182–189

Sata V, Wongsa A, Chindaprasirt P (2013) Properties of pervious geopolymer concrete using recycled aggregates. Constr Build Mater 42:33–39

Chi Y, Lihua X, Mei G, Nian H, Jie S (2014) A unified failure envelope for hybrid fibre reinforced concrete subjected to true triaxial compression. Compos Struct 109:31–40

Acknowledgments

This study was supported by the Center for Aquatic Ecosystem Restoration (CAER) of the Eco-star project form the Ministry of Environment (MOE), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oh, RO., Cha, SS., Park, SY. et al. Mechanical properties and water purification characteristics of natural jute fiber-reinforced non-cement alkali-activated porous vegetation blocks. Paddy Water Environ 12 (Suppl 1), 149–156 (2014). https://doi.org/10.1007/s10333-014-0433-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10333-014-0433-3