Abstract

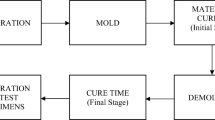

In the natural rubber latex industries, a huge amount of sludge waste is produced in different processes, which creates potential for use as reinforcing filler in plastic composites. The present work aimed to investigate the effects of sludge waste generated from the manufacturing process of fresh latex pond (FLSF) and concentrated latex processing (CLSF) on the thermal, mechanical, and physical properties of polypropylene (PP) composites. Composite samples were produced using a twin-screw extruder and a compression molding machine. From experiments, particle size analysis showed that FLSF had a smaller particle size than CLSF. For both the reinforcing fillers with increasing addition from 30 to 50 wt%, crystallinity degrees increased by about 3.30% and 7.80% for the composites with FLSF and CLSF, respectively. The strength of tension and flexure in the PP composites reduced continuously with an increase of the sludge waste contents in a range of 30–70 wt%, but the modulus from tension and flexure, hardness, and water absorption (WA) increased. The PP composites produced from FLSF displayed superior strength, modulus, hardness, and WA than those produced from CLSF. Further, the morphological, mechanical, and physical properties of the PP-sludge composites were improved with addition of maleic anhydride-grafted polypropylene. The aforementioned results showed that latex sludge waste could be used as an effective filler in plastic composites.

Similar content being viewed by others

Data availability statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Industry Outlook 2021–2023: Natural rubber processing, https://www.krungsri.com/. Accessed Feb 2022

Herculano RD, Alencar De Queiroz AA, Kinoshita A, Oliveira ON, Graeff CFO (2011) On the release of metronidazole from natural rubber latex membranes. Mater Sci Eng C 31:272–275

Panrata K, Boonmea P, Taweepredab W, Pichayakorna W (2012) Formulations of natural rubber latex as film former for pharmaceutical coating. Procedia Chem 4:322–327

Chen B, Luo Z, Chen H, Chen C, Cai D, Qin P, Cao H, Tan T (2020) Wood plastic composites from the waste lignocellulosic biomass fibers of bio-fuels processes: a comparative study on mechanical properties and weathering effects. Waste Biomass Valori 11:1701–1710

Chittella H, Yoon WL, Ramarad S, Lai ZW (2021) Rubber waste management: a review on methods, mechanism, and prospects. Polym Degrad Stab 194:109761

Uttraporn T, Sucharitaku S, Theeraraj G, Yuwaree C, Navanugraha C, Hutacharoen R (2012) Waste water minimization: utilization of rubber latex residue and swine dung as fertilizer for para rubber seedling growth. Environ Nat Resour 10:53–60

Samyn P, Driessen F, Stanssens D (2020) Natural rubber composites for paper coating applications. Mater Proc 2:29–37

Taweepreda W (2013) Rubber recovery from centrifuged natural rubber latex residue using sulfuric acid. Songklanakarin J Sci Technol 35:213–216

Intrasungkha N, Laeh S, Boonsawang P (2008) Enhancement of sludge granulation in anaerobic treatment of concentrated latex wastewater. Songklanakarin J Sci Technol 30:111–119

Homkhiew C, Boonchouytan W, Cheewawuttipong W, Ratanawilai T (2018) Potential utilization of rubberwood flour and sludge waste from natural rubber manufacturing process as reinforcement in plastic composites. J Mater Cycles Waste Manag 20:1792–1804

Vichaphund S, Intiya W, Kongkaew A, Loykulnant S, Thavorniti P (2012) Utilization of sludge waste from natural rubber manufacturing process as a raw material for clay-ceramic production. Environ Technol 33:2507–2510

Srivabut C, Ratanawilai T, Hiziroglu S (2021) Statistical modeling and response surface optimization on natural weathering of wood–plastic composites with calcium carbonate filler. J Mater Cycles Waste Manag 23:1503–1517

Jawjit S, Liengcharernsit W (2010) Anaerobic treatment of concentrated latex processing wastewater in two-stage upflow anaerobic sludge blanket. Can J Civ Eng 37:805–813

Srivabut C, Ratanawilai T, Hiziroglu S (2019) Response surface optimization and statistical analysis of composites made from calcium carbonate filler-added recycled polypropylene and rubberwood fiber. J Thermoplast Compos Mater 35:391–416

Ratanawilai T, Srivabut C (2022) Physico-mechanical properties and long-term creep behavior of wood-plastic composites for construction materials: effect of water immersion times. Case Stud Constr Mater 16:e00791

Sair S, Oushabi A, Kammouni A, Tanane O, Abboud Y, El Bouari A (2018) Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud Constr Mater 8:203–212

Appu SP, Ashwaq O, Al-Harthi M, Yunusa U (2021) Fabrication and characterization of composites from recycled polyethylene and date palm seed powder. J Thermoplas Compos Mater 34:316–327

Teaca C, Tanasa F, Zanoaga M (2016) Multi-component polymer systems comprising wood as bio-based component and thermoplastic polymer matrices – an overview. BioRes 13:4728–4769

Peng Y, Liu R, Cao J, Chen Y (2014) Effects of UV weathering on surface properties of polypropylene composites reinforced with wood flour, lignin, and cellulose. Appl Surf Sci 317:385–392

Huang R, Zhang X, Chen Z, Wan M, Wu Q (2020) Thermal stability and flame resistance of the coextruded wood-plastic composites containing talc-filled plastic shells. Int J Polym Sci 23:1435249

Jamil MS, Ahmad I, Abdullah I (2006) Effects of rice husk filler on the mechanical and thermal properties of liquid natural rubber compatibilized high-density polyethylene/natural rubber blends. J Polym Res 13:315–321

Beg MDH, Pickering KL (2008) Accelerated weathering of unbleached and bleached kraft wood fibre reinforced polypropylene composites. Polym Degrad Stabi 93:1939–1946

Worrall WE (1986) Clay and ceramic raw materials. Elsevier, New York

Homkhiew C, Rawangwong S, Boonchouytan W, Thongruang W, Ratanawilai T (2018) Composites from thermoplastic natural rubber reinforced rubberwood sawdust: effects of sawdust size and content on thermal, physical, and mechanical properties. Int J Polym Sci 2018:1–11

Xu K, Tu D, Chen T, Zhong T, Lu J (2016) Effects of environmental-friendly modified rubber seed shell on the comprehensive properties of high density polyethylene/rubber seed shell composites. Ind Crop Prod 91:132–141

Wu H, Liang X, Huang L, Xie Y, Tan S, Cai X (2016) The utilization of cotton stalk bark to reinforce the mechanical and thermal properties of bio-flour plastic composites. Constr Build Mater 118:337–343

Siriwong C, Sridang P, Danteravanich S (2009) Utilization of centrifuged residue from concentrated latex factories and ash from smoked rubber sheet factories as a binder in solidification of decorated materials. Research Report, The Thailand Research Fund (TRF)

Spiridon I, Darie RN, Kangas H (2016) Influence of fiber modifications on PLA/fiber composites; behavior to accelerated weathering. Compos B Eng 92:19–27

Du Y, Wu T, Yan N, Kortschot MT, Farnood R (2014) Fabrication and characterization of fully biodegradable natural fiber-reinforced poly(lactic acid) composites. Compos B Eng 56:717–723

Spiridon I, Paduraru OM, Rudowski M, Kozlowski M, Darie RN (2012) Assessment of changes due to accelerated weathering of low-density polyethylene/feather composites. Ind Eng Chem Res 51:7279–7286

Yang HS, Kiziltas A, Gardner DJ (2013) Thermal analysis and crystallinity study of cellulose nanofibril-filled polypropylene composites. J Therm Anal Calorim 113:673–682

Xie L, Grueneberg T, Steuernagel L, Ziegmann G, Militz H (2010) Influence of particle concentration and type on flow, thermal, and mechanical properties of wood-polypropylene composites. J Rein Plas Compos 29:1940–1951

Zheng J, Siegel RW, Toney CG (2003) Polymer crystalline structure and morphology changes in nylon-6/ZnO nanocomposites. J Polym Sci Part B: Polym Phys 41:1033–1050

Sadasivuni KK, Saiter A, Gautier N, Thomas S, Grohens Y (2013) Effect of molecular interactions on the performance of poly(isobutylene-co-isoprene)/graphene and clay nanocomposites. Colloid Polym Sci 291:1729–1740

Fordiani F, Aubry T, Grohens Y (2009) Structural changes evidenced by rheology in PPgMA nanocomposites during oxidative ageing. J Appl Polym Sci 114:4011–4019

Yuan W, Guo M, Miao Z, Liu Y (2010) Influence of maleic anhydride grafted polypropylene on the dispersion of clay in polypropylene/clay nanocomposites. Polym J 42:745–751

Jang LW, Kim ES, Kim HS, Yoon JS (2005) Preparation and characterization of polypropylene/clay nanocomposites with polypropylene-graft-maleic anhydride. J Appl Polym Sci 98:1229–1234

Elamin MAM, Li SX, Osman ZA, Otitoju TA (2020) Preparation and characterization of wood-plastic composite by utilizing a hybrid compatibilizer system. Ind Crops Prod 154:112659

Ratanawilai T, Nakawirot K, Deachsrijan A, Homkhiew C (2014) Influence of wood species and particle size on mechanical and thermal properties of wood polypropylene composites. Fibers Polym 15:2160–2168

Mohanty S, Nayak SK (2006) Interfacial, dynamic mechanical, and thermal fiber reinforced behavior of MAPE treated sisal fiber reinforced HDPE composites. J Appl Polym Sci 102:3306–3315

Gulitah V, Liew KC (2018) Effect of plastic content ratio on the mechanical properties of wood-plastic composite (WPC) made from three different recycled plastic and acacia fibres. Trans Innov Sci Technol 5:184–189

Ratanawilai T, Taneerat K (2018) Alternative polymeric matrices for wood-plastic composites: effects on mechanical properties and resistance to natural weathering. Constr Build Mater 172:349–357

Pao CZ, Yeng CM (2019) Properties and characterization of wood plastic composites made from agro-waste materials and post-used expanded polyester foam. J Thermoplast Compos Mater 32:951–966

Intiya W, Thepsuwan U, Sirisinha C, Sae-Oui P (2017) Possible use of sludge ash as filler in natural rubber. J Mater Cycles Waste Manag 19:774–781

Benhamou AA, Boussetta A, Nadifiyine M, Moubarik A (2021) Effect of alkali treatment and coupling agent on thermal and mechanical properties of Opuntia ficus-indica cladodes fibers reinforced HDPE composites. Polym Bull. https://doi.org/10.1007/s00289-021-03619-8

Kaymakci A, Birinci E, Ayrilmis N (2019) Surface characteristics of wood polypropylene nanocomposites reinforced with multi-walled carbon nanotubes. Compos B Eng 157:43–46

Chun KS, Yeng CM, Hussiensyah S (2018) Green coupling agent for agro-waste based thermoplastic composites. Polym Compos 39:2441–2450

Husseinsyah S, Chun KS, Hadi A, Ahmad R (2016) Effect of filler loading and coconut oil coupling agent on properties of low-density polyethylene and palm kernel shell eco-composites. J Vinyl Addit Technol 22:200–205

Chindaprasirt P, Hiziroglu S, Waisurasingha C, Kasemsiri P (2015) Properties of wood flour/expanded polystyrene waste composites modified with diammonium phosphate flame retardant. Polym Compos 36:604–612

Kajaks J, Kalnins K, Naburgs R (2018) Wood plastic composites (WPC) based on high-density polyethylene and birch wood plywood production residues. Int Wood Prod J 9:15–21

Acknowledgements

The authors gratefully acknowledge the financial support from the Thailand Science Research and Innovation (Research Grant Code: 64A171000042) and the Rajamangala University of Technology Srivijaya (RMUTSV), Thailand.

Funding

Thailand Science Research and Innovation, 64A171000042, Chatree Homkhiew.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Homkhiew, C., Srivabut, C., Ratanawilai, T. et al. Characterization of polypropylene composites using sludge waste from the natural rubber latex industry as reinforcing filler. J Mater Cycles Waste Manag 25, 1444–1456 (2023). https://doi.org/10.1007/s10163-023-01621-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01621-y