Abstract

An evaluation of various metal purification processes subsequent to the leaching processing of the neodymium (Nd) product from neodymium–iron–boron (Nd–Fe–B) magnets has been conducted. These post-leaching purification processes included precipitation; replacement and electrolysis were studied in order to check the purity of the recovered neodymium. A hydrometallurgical investigation was adopted to digest the metal content of the scrap Nd–Fe–B magnets for the recovery of valuable Nd metal and other metals such as Fe, B, Co and Ni. The effect of leaching conditions such as solid-to-liquid ratio and temperature were optimized and 100 % Nd, 100 % Fe, 100 % B and 85.87 % Co leaching efficiencies were achieved under these conditions. The coating material of the magnet, Ni, achieved 50 % impregnation after increasing the reaction temperature to 70 °C. The metals present in the optimal leaching solution were recovered 99 % by pH adjustment. However, the replacement had the highest separation efficiency for the recovery of Nd metal. Further, the optimal leaching Nd–Fe–B solution was subjected to the electrolysis processes in order to verify the recovery efficiency for all metals.

Similar content being viewed by others

References

Osamu T, Toru H, Okabe TH, Umetsu Y (2006) Recovery of neodymium from a mixture of magnet scrap and other scrap. J Alloy Compd 408–412:387–390. doi:10.1016/j.jallcom.2005.04.094

Rivoirard S, Noudem JG, De Rango P, Fruchart D, Liesert S, Soubeyroux JL (2000) Anisotropic and coercive powders for bonded magnets. In: Kanedo H, Homma M, Okada M (eds) The Japan Institute of Metals Proceedings Volume 14(REMXVI2000) rare-earth magnets and their applications. The Japan Institute of Metals, Japan, p 347

Sessoli R, Powell AK (2009) Strategies towards single molecule magnets based on lanthanide ions. Coord Chem Rev 253(19–20):2328–2341. doi:10.1016/j.ccr.2008.12.014

Hadfield H (1989) Magnetic materials in the third millennium. Mater Des 10(5):222–230. doi:10.1016/S0261-3069(89)80058-5

Sagawa M, Hirosawa S, Yamamoto H, Fujimura S, Matsuura Y (1987) Nd–Fe–B permanent magnet materials. Jpn J Appl Phys 26:785–800. doi:10.1143/JJAP.26.785

Schultz L, Schnitzke K, Wecker J (1989) Preparation and properties of mechanically alloyed rare earth permanent magnets. J Magn Magn Mater 80(1):115–118. doi:10.1016/0304-8853(89)90336-3

Zakotnik M, Williams AJ, Harris IR (2004) Proceedings of the 18th workshop on high performance magnets and their applications, vol 1, p 267

Luborsky FE, Mendelsohn LI, Paine TO (1957) Reproducing the properties of alnico permanent magnet alloys with elongated single-domain cobalt–iron particles. J Appl Phys 28(344):344. doi:10.1063/1.1722744

Zakotnik M, Harris IR, Williams AJ (2008) Possible methods of recycling NdFeB-type sintered magnets using the HD/degassing process. J Alloy Compd 450(1–2):525–531. doi:10.1016/j.jallcom.2007.01.134

Brown D, Ma B, Chen Z (2002) Developments in the processing and properties of NdFeb-type permanent magnets. J Magn Magn Mater 248(3):434–440. doi:10.1016/S0304-8853(02)00334-7

Green JA (2009) Defense, energy markets should brace for shortages of key materials. National Defense Industrial Association; U.S. Lacks Data on Supply of Minerals Critical to Economy, National Security; Defense Stockpile is Ineffective. National Academy of Sciences, http://www8.nationalacademies.org/onpinews/newsitem.aspx?RecordID=10052007

Keller T (2011) Chinese rare earths supply squeeze doomed. The Globe and Mail, April 28

Morrison WM, Tang R (2012) China’s rare earth industry and export regime: economic and trade implications for the United States. (CRS Report). Congressional Research Service, pp 23–31. http://fas.org/sgp/crs/row/R42510.pdf

Curtis N (2010) Rare earths, we can touch them everyday, Lynas presentation at the JP Morgan Australia Corporate Access Days, New York, 27–28 September 2010. http://www.lynascorp.com/Presentations/2010/Lynas_Corps_J_P_Morgan_Presentation_September_New_York__FINAL.pdf

Metalpages, 2011–2012 http://www.metal-pages.com/metals/neodymium/metal-prices-news-information/. Accessed 2 Apr 2014 and 20 Mar 2014

China rare earth permanent magnet industry report, 2011–2012. Research in China. http://www.researchinchina.com/Htmls/Report/2012/6335.html

China rare earth, http://www.cre.net. Accessed 19 Jul 2014

Disposal of magnets, http://www.mceproducts.com/knowledgebase/article/article-dtl.asp?id=11. Accessed 19 July 2014

Zakotnik M, Harris IR, Williams AJ (2009) Multiple recycling of NdFeB-type sintered magnets. J Alloys Compd 469:314–321. doi:10.1016/j.jallcom.2008.01.114

Kawasaki T, Itoh M, Machida K (2003) Reproduction of Nd–Fe–B sintered magnet scraps using a binary alloy blending technique. Mater Trans 44(9):1682–1685. doi:10.2320/matertrans.M-M2013813

Zhihong S (2012) Method for extracting neodymium from neodymium-iron boron electroplating pro-processing acid washing waste water. Patent No. CN 200710156061 A, accessed 17 Aug 2014

Department of Energy News: process recovers valuable neodymium from magnetic waste, US 2001, http://www.eurekalert.org/features/doe/2001-07/dl-nlf060502.php. Accessed 17 Aug 2014

Hiroko T (2010) Japan recycles minerals from used electronics http://www.nytimes.com/2010/10/05/business/global/05recycle.html?pagewanted=all. Accessed 24 June 2012

Itoh M, Masuda M, Suzuki S, Ken-ichi Machida (2004) Recycling of rare earth sintered magnets as isotropic bonded magnets by melt-spinning. J Alloy Compd 374(1–2):393–396 http://www.sciencedirect.com/science/article/pii/S0925838803012453

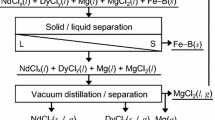

Okabe TH, Takeda O, Fukuda K, Umetsu Y (2003) Direct extraction and recovery of neodymium metal from magnet scrap. Mater Trans 44(4):798–801

Taiwan Environmental Protection Agency [TEPA]: http://www.niea.gov.tw/analysis/method/ListMethod.asp?methodtype=REFUSE (in Chinese). Accessed 18 Apr 2011

Novoselova A, Smolenski V (2013) Electrochemical behavior of neodymium compounds in molten chlorides. Electrochim Acta 87:657–662

Brenner A (1963) Electrodeposition of alloys, vol 1. Academic Press, New York

Taxil P, Chamelot P, Massot L, Hamel C (2003) Electrodeposition of alloys or compounds in molten salts and applications. J Min Metall 39:177–200

Gibilaro M, Massot L, Chamelot P, Taxil P (2008) Study of neodymium extraction in molten fluorides by electrochemical co-reduction with aluminium. J Nucl Mater 382:39–45

Baba AA, Adekola FA (2011) Beneficiation of a Nigerian sphalerite mineral: solvent extraction of zinc by Cyanex®272 in hydrochloric acid. Hydrometal 109(2011):187–193

Bard AJ, Parsons R, Jordan J (1985) Standard potentials in aqueous solution. CRC Press, USA

Ramachandra Rao SR (2006) Resource recovery and recycling from metallurgical wastes. Elsevier, UK

Morrison JW, Palmer GR (1990) Proceedings of the second international symposium, recycling of metals and engineered materials, pp 593–609

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, CH., Yen, HY., Liao, CH. et al. Hydrometallurgical processing of Nd–Fe–B magnets for Nd purification. J Mater Cycles Waste Manag 19, 102–110 (2017). https://doi.org/10.1007/s10163-015-0382-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-015-0382-y