Abstract

We prepared sole TiO2 nanotube arrays (NAs) using one-step and two-step anodic oxidation followed by annealing. These TiO2 NAs were characterized by X-ray diffraction (XRD), Raman spectrum, scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), UV-Vis absorption spectrum, photoluminescence spectrum (PL), and contact angle measurement. The XRD and Raman spectra results suggest only anatase TiO2 phase formed after anodic oxidation followed by annealing. The XPS spectra showed that the surface electron density change in the TiO2 NAs prepared by one-step anodic oxidation compared to those prepared by two-step one. Therefore, the former could absorb visible light more intensely. The PL and photocurrent measurement proved that the recombination rate of electron-hole pairs was suppressed in the sample prepared by two-step anodic oxidation followed by annealing as the degree of crystallinity increased and crystal defects decreased compared with the sample prepared by one-step anodic oxidation followed by annealing. However, the latter possessed better wettability to water and oil and thereby more active sites. The combined action made the sole TiO2 NAs prepared by one-step anodic oxidation exhibited rather similar high photocatalytic activity in RhB degradation under the irradiation of simulated solar light to those prepared by two-step one. Therefore, solar-responsive sole TiO2 NAs with high photocatalytic activity were possible to be prepared.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Photocatalysis has been investigated extensively for more than 45 years since Fukushima [1] discovered water splitting and following hydrogen generation from the electrolysis system composed of TiO2 as anode and Pt cathode as under UV irradiation. Some breakthroughs have also been made [2, 3]. Recently, most works are focusing on the photocatalytic mechanism clarification [4, 5] and the photocatalytic activity improvement of photocatalyst nanoparticles under irradiation of visible light [6,7,8]. However, the recycling difficulty raised their running costs and therefore obstructed the photocatalysis applications in sewage degradation although the nanoparticles always show excellent photocatalytic activity [9]. Therefore, immobilization of photocatalyst nanoarchitecture seems to be particularly urgent. The immobilization in the form of films or coatings should be one of the most facile methods [10]. Furthermore, photocatalyst films and coatings show a great application potential in air purification, sterilization, and sensor [11,12,13].

Among the methods to prepare TiO2 coatings, anodic oxidation exhibits advantages such as simple procedure, commercial feasibility, and relatively high efficiency. More importantly, the as-prepared TiO2 nanotube (NT) coatings possess excellent photocatalytic activity in the degradation of organic dyes after the following crystallization since TiO2 NT coatings have large specific area [14], great sunlight harvest ability [15], and fast charge-transfer [16]. However, we still cannot use TiO2 NT coatings into practical applications due to its relative low visible-light-responsive photocatalytic activity derived from its large band gap and fast hole-electron recombination [4]. Therefore, people have attempted to narrow the band gap by doping them with metallic ions including Zr4+ [17], Fe3+ [18], Ti3+ [19] or with non-metallic ions such as B [20], N [20, 21], and C [21, 22] and among others. In addition, coupling with semiconductors including Cu2O [23], Ag2O [24], La2O3 [25], or with noble metallic nanoparticles such as Ag [26], Pt [27], and Au [28] is also an effective method. However, the enhancement on photocatalytic activity always accompanied by complicated procedure, and thereby high producing cost. In addition, scientists and engineers have tried their best to prepare perfect morphologies of TiO2 NTs coatings through two-step anodic oxidation [29,30,31]. The two-step anodic oxidation also increases the preparation cost. We have to prepare TiO2 coatings with high photocatalytic activity through facile anodic oxidation at the lowest possible cost before we could use them practically. One-step anodic oxidation becomes an inevitable choice without doubt.

In the present work, we prepared sole TiO2 NT coatings with facile one-step anodic oxidation and compared the photocatalytic activities of the TiO2 NT coatings prepared by one-step and two-step anodic oxidation under the irradiation of a weak simulated solar light. The research findings can guide the preparation of solar light-responsive TiO2 NT coatings with high photocatalytic activity and their practical applications in organic pollutants.

Experimental

Preparation of TiO2 NAs

TiO2 NAs are prepared by a facile anodic oxidation method. The preparation process is described as follows. Firstly, Ti foils (30 mm × 20 mm × 0.127 mm, 99.7%, Alfa Aesar) are cleaned in HCl (5 mol/L), ethanol, and deionized water sequentially and separately for 10 min using ultrasonic bath. The cleaned Ti foils are then dried in air at room temperature. Secondly, anodic oxidation is performed in a home-made electrolytic cell with the cleaned Ti foil as the anode and Pt foil (20 mm × 20 mm × 0.025 mm, 99.9%, Alfa Aesar) as the cathode. The electrolyte is composed of ammonium fluoride (1.078 g), deionized water (6 mL), and ethylene glycol (194 mL). The anodic oxidation is conducted at 50 V for 20 min. Finally, the as-prepared samples are immersed in ethanol for 2 h and then dried in air at room temperature. The as-prepared samples need further annealing to drive amorphous TiO2 NAs crystallization. The samples before and after annealing at 723 K for 2 h with a heating rate of 2 K/min are named as sample A and sample A + H, separately. To investigate the coupling influence of Ag3PO4 on photocatalytic activity of TiO2 NAs, the loading of Ag3PO4 nanoparticles on TiO2 NAs is also conducted by immersing sample A + H into NaH2PO4 solution (0.03 mol/L) for 5 min and then transferring to AgNO3 solution (0.05 mol/L) holding for 5 min. The dipping-treated samples are then washed with deionized water. The above dipping treatment is repeated for five times. The as-prepared sample is denoted as A + H + I.

To compare the photocatalytic activity of TiO2 NAs prepared by one-step and two-step anodic oxidation, we also performed two-step anodic oxidation to make the morphology of TiO2 NAs perfect. The detailed process is as follows. The Ti foil coated with TiO2 NAs prepared by one-step anodic oxidation is immersed into deionized water immediately after the first anodic oxidation, and then it is cleaned in ultrasonic bath to peel the formed TiO2 NAs. One-second-step anodic oxidation was conducted in the same electrolyte at 50 V for 30 min. The as-prepared sample after the above annealing is labeled 2A + H. All the as-received chemical reagents were analytical grade ones.

Characterization

The crystal information of the as-prepared samples A, A + H, A + H + I, and 2A + H is given by X-ray diffraction (XRD, D8 Advance, Bruker, Germany) and Raman spectrometer (DXR Microscope, Thermo Fisher Scientific, USA). The surface morphologies and cross sections of the as-prepared samples are observed using scanning electron microscopy (SEM, Sigma 300, Zeiss, Germany). The surface element analysis is performed with X-ray photoelectron spectroscopy (XPS, Escalab 250Xi, Thermo Fisher Scientific, USA). The UV-Vis absorption spectroscopy is recorded using an UV-Vis spectrophotometer (UV 3600 Plus, Shimadzu, Japan) in the wavelength range of 300~900 nm. The recombination of light-induced electron-hole pairs is examined by photoluminescence spectrometer (PL, iHR320, Horiba, Japan). Photocurrent density was measured with an electrochemical workstation (CHI 650E, Chenhua Co. Ltd., China) using 0.1 mol/L Na2SO4 as the electrolyte. The contact angle measurement of the as-prepared samples to water and oil (vacuum pump oil) is performed using contact angle meter (DSA30, Krüss, Germany).

Evaluation of photocatalytic activity

Before photocatalytic activity evaluation of the as-prepared samples, all the samples are cleaned in deionized water and dried in air. The as-prepared samples are then irradiated with UV light for 1 h to degrade residual organic pollutants. A commercially available organic dye rhodamine B (RhB) is chosen as the target pollutant. The photocatalytic RhB degradation is performed under the irradiation of a simulated solar light (CEL-HXF 300, Aulight Co. Ltd., China) with the optical power density of 45 mW/cm2, which is smaller than half the AM1.5 of 100 mW/cm2. RhB molecular adsorption-desorption equilibrium is achieved through the placement in the darkness for 30 min before the evaluation. The concentration of RhB solution is monitored using a UV-Vis spectrophotometer (DR3900, Hach, USA).

Results and discussion

Identification of crystal phases

The XRD patterns of the as-prepared samples are illustrated as shown in Fig. 1. We can observe the diffraction peaks of Ti (marked with symbol T), while the diffraction peaks of anatase or rutile TiO2 cannot seen in the sample after the anodic oxidation (Fig. 1a). The intensive peaks of anatase TiO2 appeared in sample A + H (Fig. 1b), which means that amorphous TiO2 formed in the anodic oxidation and amorphous TiO2 transferred to anatase TiO2 in the following annealing. The result is consisted with the reported works [32,33,34]. Furthermore, the (210) plane diffraction peak of Ag3PO4 was also observed in sample A + H + I, which indicates that the dipping method made Ag3PO4 particles adhered to TiO2 NAs. In addition, we can also see that more intensive (101) plane diffraction peak of anatase TiO2 in sample 2A + H. It suggests that anatase TiO2 crystals with higher crystallinity degree formed in the sample prepared by two-step anodic oxidation followed by annealing. Figure 2 shows the Raman spectroscopy of the as-prepared samples. Any peak cannot be found in sample A, while intensive peaks at 144, 394, 516, and 635 cm−1 are observed in the other samples. According to references [35, 36], the peaks correspond to four Raman active modes of anatase TiO2 Eg, B1g, A1g, and Eg, respectively. The result confirmed the conclusion obtained from Fig. 1.

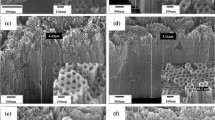

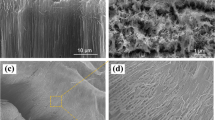

Morphologies and cross sections

Figure 3 shows the morphologies and cross sections of the as-prepared samples. We can see that TiO2 NAs decorated with some nanoparticles have formed in sample A (Fig. 3a), and the average thickness of the coatings is about 4 μm (Fig. 3c). With energy dispersive spectrometer (EDS) analysis, the decorated nanoparticles is determined to be TiO2 ones, which peeled off after ultrasonic cleaning. We also noted that the morphology and cross section of the TiO2 NAs hardly changed after annealing at 723 K except the disappearance of TiO2 nanoparticles (Fig. 3b, d). With further dipping treatment in AgNO3 and NaH2PO4 solution, Ag3PO4 nanoparticles formed and adhered to the TiO2 NAs and they still reserved even experienced ultrasonic cleaning (Fig. 3e, g). It indicates the adhesion of Ag3PO4 nanoparticles to the coatings should be firm enough. The SEM images of the morphology and cross section of the sample prepared by two-step anodic oxidation followed by annealing (sample 2A + H) are shown in Fig. 3f, h, respectively. The cracking of the formed TiO2 NAs is rather evident, and the thickness of the coatings should be a bit greater than sample A + H since the duration of anodic oxidation prolonged.

Photocatalytic activity

Photocatalytic degradation of RhB under the irradiation of weak simulated solar light (45 mW/cm2) was monitored with the results shown in Fig. 4. With the increase in irradiation time, the concentration of RhB aqueous solution decreased except the one without TiO2 NAs (blank). It indicates that RhB does not degrade under the irradiation of simulated solar light. For all the RhB aqueous solutions with TiO2 NAs, their concentrations decreased to an almost same value after irradiation of 60 min. It suggests sample A + H, A + H + I and 2A + H exhibited similar photocatalytic performance in the photocatalytic degradation of RhB. However, the photocatalytic activity of sample A + H + I began to drop as the simulated solar irradiation continued although the other two samples A + H and 2A + H still showed high photocatalytic activity during the whole irradiation. The concentration of RhB aqueous solution decreased to 2.2 mg/L, which was about 44% of the initial concentration. What is more, the samples A + H and 2A + H possessed rather similar photocatalytic activity during the whole process. In other words, the TiO2 NAs prepared by one-step anodic oxidation and two-step anodic oxidation showed the similar photocatalytic activity. Therefore, one-step anodic oxidation method is capable of preparing solar-responsive TiO2 NAs with high photocatalytic activity.

Surface analysis

The XPS spectra of the as-prepared samples are shown in Fig. 5. Figure 5a shows the XPS spectrum of Ti 2p, in which the BE values of Ti 2p3/2 and Ti 2p1/2 of the samples prepared by one-step anodic oxidation located at 459.3 and 465.0 eV, respectively. They show a positive shift of 0.7 eV compared to those of the sample prepared by two-step anodic oxidation. It is reported that the BE values of Ti 2p3/2 and Ti 2p1/2 in TiO2 NAs usually appears at 458.5 ± 0.4 and 464.2 ± 0.4 eV [37,38,39]. The XPS information is in good agreement with that prepared by two-step anodic oxidation. The shift of the BE values for the samples prepared by one-step anodic oxidation indicates the surface electron density reduce of TiO2. Figure 5b shows the O 1 s spectra, in which the peak at 529.9 eV of the sample prepared by two-step anodic oxidation correspond to Ti-O. The result fits perfectly the reported values [40, 41]. Three clear peaks at 530.5, 530.6, and 530.7 eV in the samples prepared by one-step anodic oxidation are also confirmed as those of Ti-O bond in TiO2 [42]. Furthermore, some weak peaks around 532.0 eV are also detected in the samples prepared by one-step anodic oxidation. These peaks correspond to hydroxyl groups or H2O, which are rather important for enhancing the photocatalytic activity of TiO2 [43, 44].

Figure 6 shows the optical absorption spectra of the as-prepared samples prepared by one-step and two-step anodic oxidation followed by annealing. We can clearly see that all the samples absorb all colors of light within the wavelength of 300~900 nm. The absorption thresholds of samples A + H, A + H + I, and 2A + H are determined to be about 460, 495, and 430 nm, respectively. From the above values, we calculated the band gaps of these samples to be 2.7, 2.5, and 2.88 eV, respectively. Therefore, the sample prepared by one-step anodic oxidation (A + H) can absorb more visible light than that prepared by two-step anodic oxidation (2A + H). The combination of TiO2 NAs with Ag3PO4 nanoparticles makes the band gap reduce to 2.5 eV and thereby they can absorb visible light more intensively.

Photoluminescence (PL) analysis shown in Fig. 7 are also performed as it could provide powerful information of photogenerated charge carrier behavior of semiconductors [45]. As shown in Fig. 7, all the samples exhibited single obvious PL single peak at a wavelength of 582 nm, which suggests that the annealing, two-step anodic oxidation and the combination with Ag3PO4 nanoparticles were not enough to generate a new PL signal. Generally, it is believed that lower PL intensity means an enhanced separation and transfer of photogenerated electrons trapped in semiconductor [45,46,47,48]. Therefore, we consider that the recombination rate of photogenerated hole-electron pairs in samples 2A + H and A + H + I is lower than that in sample A + H.

Figure 8 shows the transient photocurrent response of the as-prepared samples under the irradiation of simulated solar light. We noted that the photocurrent density of sample A + H was rather faint even can be negligible. The faint photocurrent density should ascribe to the high recombination rate of photogenerated hole-electron pairs. After the coupling with Ag3PO4 nanoparticles, the recombination of hole-electron pairs were evidently suppressed which resulted in a great photocurrent density value as observed in Fig. 8. In addition, the photocurrent density of sample 2A + H was also much greater than that of sample A + H.

The absorption of dye molecules to the photocatalyst surface is the first step of photocatalytic degradation. Therefore, the wettability of TiO2 NAs to water and oil is rather important to their photocatalytic degradation performance of RhB in aqueous solution [49]. Table 1 shows the contact angles of the as-prepared samples to water and oil. It can be clearly seen that sample A + H shows smaller contact angles to water and oil than samples 2A + H and A + H + I. It indicates that sample A + H can absorb more water and RhB molecules than samples A + H + I and 2A + H.

Generally, the TiO2 NAs prepared by two-step anodic oxidation followed by annealing possess more perfect morphologies, higher specific area, and greater crystallinity, thereby better photocatalytic performance [50,51,52]. Therefore, people have tried their best to prepare TiO2 NT coatings with perfect morphologies through two-step anodic oxidation although it takes more cost and complicated procedure. In this work, the TiO2 NAs prepared by one-step anodic oxidation followed by annealing (sample A + H) showed an extremely similar photocatalytic activity in the degradation of RhB under the irradiation of weak simulated solar light comparing to those prepared by two-step anodic oxidation (sample 2A + H). It means we can prepare TiO2 NAs with higher photocatalytic performance at lower cost, which can greatly promote their practical applications in industrial sewage treatment, air purification, and among others. As for the similar photocatalytic performance of the samples prepared by one-step and two-step anodic oxidation, we present some analysis and discussion as follows.

The photogenerated holes and electrons produce some chemical species including H2O, OH− and O2 to produce •OH, O2•- and H2O2 [53]. However, the contribution of O2•- in oxidation reactions such as RhB photocatalytic degradation is quite smaller than that of •OH and holes as the amounts of the former are rather small [53, 54]. Therefore, we believe that the amounts of the escaped holes and resulting •OH determine the photocatalytic activity of TiO2 NT coatings in oxidizing RhB molecules. In other words, all the factors promoting to produce holes and •OH radicals could enhance the photocatalytic activity of TiO2 NT coatings in degrading RhB. From the results presented by the PL spectra (Fig. 7), the recombination rate of hole-electron pairs in sample A + H was greater than those in samples A + H + I and 2A + H. Therefore, we can safely conclude that the amounts of active oxidizing species to mineralize RhB molecules on the surface of sample A + H is smaller than those of samples A + H + I and 2A + H. The photocurrent response in Fig. 8 also proved our deduction.

On the other hand, sample A + H could absorb more visible light compared to sample 2A + H in Fig. 6. The enhanced visible light absorption should relate to the surface state change of TiO2 NAs. From the results in XPS, the positive shift of Ti 2p and O 1 s corresponds to the surface electron density change. It results in more surface defects, which enhanced the visible light absorption. The further enhancement in visible light absorption of sample A + H + I should attribute to the coupling with Ag3PO4 nanoparticle [55]. Furthermore, the wettabilities of sample A + H to water and oil are better than those of sample 2A + H (Fig. 8), which means that the surface of sample A + H could absorb more RhB molecules and thereby more active sites.

The above positive factors, such as intensive visible light absorption and better wettabilities to water and oil, and negative factors, including greater recombination rate of hole-electron pairs, and high degree of crystallinity, made sample A + H possess rather similar photocatalytic degradation performance of RhB compared with sample 2A + H.

Conclusions

Sole TiO2 nanotube arrays (NAs) are prepared by one-step and two-step anodic oxidation followed by annealing. The comprehensive analysis revealed that anatase TiO2 NAs were formed by anodic oxidation followed by annealing no matter one-step or two-step anodic oxidation. Two-step anodic oxidation increased the degree of crystallinity of TiO2 and therefore decreased the recombination rate of photogenerated electron-hole pairs compared to one-step anodic oxidation. On the other hand, TiO2 NAs prepared by one-step anodic oxidation possessed more surface defects and thereby absorbed visible light more intensely compared to the TiO2 NAs prepared by two-step anodic oxidation. More importantly, the TiO2 NAs prepared by one-step anodic oxidation exhibited better wettability to water and oil than those prepared by two-step anodic oxidation. The combined action of surface defects, degree of crystallinity, visible light absorption, and wettability to water and oil made the sole TiO2 NAs prepared by one-step anodic oxidation followed by annealing had rather similar excellent photocatalytic activity in RhB degradation under the irradiation of simulated solar light compared to those prepared by two-step anodic oxidation. Therefore, one-step anodic oxidation is a facile and economic method to prepare solar-responsive TiO2 NAs with high performance.

References

Fujishima A, Honda K (1972) Electrochemical photolysis of water at a semiconductor electrode. Nature 238(5358):37–38

Asahi R, Morikawa T, Ohwaki T, Aoki K, Taga Y (2001) Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 293(5528):269–271

Chen X, Liu L, Yu PY, Mao SS (2011) Increasing solar absorption for photocatalysis with black hydrogenated titanium dioxide nanocrystals. Science 331(6018):746–750

Hoffmann MR, Martin ST, Choi W, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. Chem Rev 95(1):69–96

Linsebigler AL, Lu G, Yates JT (1995) Photocatalysis on TiO2 surfaces: principles, mechanism, and selected results. Chem Rev 95(3):735–758

Lin Z, Li J, Zheng Z, Yan J, Liu P, Wang C, Yang G (2015) Electronic reconstruction of α-Ag2WO4 nanorods for visible-light photocatalysis. ACS Nano 9(7):7256–7265

Lee K, Kim D, Roy P, Paramasivam I, Birajdar BI, Spiecker E, Schmuki P (2010) Anodic formation of thick anatase TiO2 mesosponge layers for high-efficiency photocatalysis. J Am Chem Soc 132(5):1478–1479

Hu S, Shaner MR, Beardslee JA, Lichterman M, Brunschwig BS, Lewis NS (2014) Amorphous TiO2 coatings stabilize Si, GaAs, and GaP photoanodes for efficient water oxidation. Science 344(6187):1005–1009

Kuo D, Hsu W, Yang Y (2016) From the fluorescent lamp-induced bactericidal performance of sputtered Ag/TiO2 films to re-explore the photocatalytic mechanism. Appl Catal B Environ 184:191–200

Jiang W, Qiu Z, Yao W, Zhu Y, Cui W (2017) TiO2/Al(H2PO4)3 composite film as separation-free and washing-resistance photocatalyst. Appl Catal B Environ 204:3–48

Demirci S, Dikici T, Yurddaskal M, Gultekin S, Toparli M, Celik E (2016) Synthesis and characterization of Ag doped TiO2 heterojunction films and their photocatalytic performances. Appl Surf Sci 390:591–601

Luo L, Miao L, Tanemura S, Tanemura M (2008) Photocatalytic sterilization of TiO2 films coated on Al fiber. Mater Sci Eng B 148(1-3):183–186

Rothschild A, Edelman F, Komen Y, Cosandey F (2000) Sensing behavior of TiO2 thin films exposed to air at low temperatures. Sensors Actuators B Chem 67(3):282–289

Ye Y, Feng Y, Bruning H, Yntema D, Rijnaarts HHM (2018) Photocatalytic degradation of metoprolol by TiO2 nanotube arrays and UV-LED: effect of catalyst properties, operational parameters, commonly present water constituents, and photo-induced reactive species. Appl Catal B Environ 220:171–180

Yang Z, Ma Z, Pan D, Chen D, Xu F, Chen S (2014) Enhancing the performance of front-illuminated dye-sensitized solar cells with highly [001] oriented, single-crystal-like TiO2 nanotube arrays. Ceram Int 40(1):173–180

Wang Z, Liu B, Xie Z, Li Y, Shen Z (2016) Preparation and photocatalytic properties of RuO2/TiO2 composite nanotube arrays. Ceram Int 42(12):13664–13669

Liu H, Liu G, Zhou Q (2009) Preparation and characterization of Zr doped TiO2 nanotube arrays on the titanium sheet and their photocatalytic activity. J Solid State Chem 182(12):3238–3242

Wang Q, Jin R, Zhang M, Gao S (2017) Solvothermal preparation of Fe-doped TiO2 nanotube arrays for enhancement in visible light induced photoelectrochemical performance. J Alloys Compd 690:139–144

Zhu W, Wang C, Chen J, Li Y, Wang J (2014) Enhanced field emission from Ti3+ self-doped TiO2 nanotube arrays synthesized by a facile cathodic reduction process. Appl Surf Sci 301:525–529

Georgieva J, Valova E, Armyanov S, Tatchev D, Sotiropoulos S, Avramova I, Dimitrova N, Hubin A, Steenhaut O (2017) A simple preparation method and characterization of B and N co-doped TiO2 nanotube arrays with enhanced photoelectrochemical performance. Appl Surf Sci 413:284–291

Mollavali M, Falamaki C, Rohani S (2015) Preparation of multi-doped TiO2 nanotube arrays with nitrogen, carbon and nickel with enhanced visible light photoelectrochemical activity via single-step anodization. Int J Hydrog Energy 40(36):12239–12252

Liu S, Yang L, Xu S, Luo S, Cai Q (2009) Photocatalytic activities of C-N-doped TiO2 nanotube array/carbon nanorod composite. Electrochem Commun 11(9):1748–1751

Sun Q, Peng Y, Chen H, Chang K, Qiu Y, Lai S (2016) Photoelectrochemical oxidation of ibuprofen via Cu2O-doped TiO2 nanotube arrays. J Hazard Mater 319:121–129

Deng X, Ma Q, Cui Y, Zhang H, Cheng X, Li X, Cheng M, Li B (2017) Microwave-assisted synthesis of Ag2O/reduced TiO2 nano-tube arrays photoelectrode with enhanced visible photocatalytic activity for degradation of organic pollutants. Sep Purif Technol 182:230–237

Li H, Feng B (2016) Visible-light-driven composite La2O3/TiO2 nanotube arrays: synthesis and improved photocatalytic activity. Mater Sci Semicond Process 43:55–59

Kong J, Song C, Zhang W, Xiong Y, Wan M, Wang Y (2017) Enhanced visible-light-active photocatalytic performanced on Ag nanoparticles sensitized TiO2 nanotube arrays. Superlattice Microst 109:579–587

Wang Y, Zhu Y, Zhao X, Yang X, Li X, Chen Z, Yang L, Zhu L, Gao T, Sha Z (2015) Improving photocatalytic Rhodamine B degrading activity with Pt quantum dots on TiO2 nanotube arrays. Surf Coat Technol 281:89–97

Wu L, Li F, Xu Y, Zhang JW, Zhang D, Li G, Li H (2015) Plasmon-induced photoelectrocatalytic activity of Au nanoparticles enhanced TiO2 nanotube arrays electrodes for environmental remediation. Appl Catal B Environ 164:217–224

Cho I, Choi J, Zhang K, Kim S, Jeong M, Cai L, Park T, Park J, Zheng X (2015) Highly efficient solar water splitting from transferred TiO2 nanotube arrays. Nano Lett 15(9):5709–5715

Ye M, Gong J, Lai Y, Lin C, Lin Z (2012) High-efficiency photoelectrocatalytic hydrogen generation enabled by palladium quantum dots-sensitized TiO2 nanotube arrays. J Am Chem Soc 134(38):15720–25723

Koo M, Cho K, Yoon J, Choi W (2017) Photoelectrochemical degradation of organic compounds coupled with molecular hydrogen generation using electrochromic TiO2 nanotube arrays. Environ Sci Technol 51(11):6590–6598

Wang C, Zhu W, Chen J, Hou X, Zhang X, Li Y, Wang J, Zhou F (2014) Low-temperature ammonia annealed TiO2 nanotube arrays: synergy of morphology improvement and nitrogen doping for enhanced field emission. Thin Solid Films 556:440–446

Liao J, Lin S, Zhang L, Pan N, Cao X, Li J (2012) Photocatalytic degradation of methyl orange using a TiO2/Ti mesh electrode with 3D nanotube arrays. ACS Appl Mater Interfaces 4(1):171–177

Kurian S, Seo H, Jeon H (2013) Significant enhancement in visible light absorption of TiO2 nanotube arrays by surface band gap tuning. J Phys Chem C 117(33):16811–16819

Rao BM, Roy SC (2014) Anatase TiO2 nanotube arrays with high temperature stability. RSC Adv 4(72):38133–38139

Krengvirat W, Sreekantan S, Noor AM, Negishi N, Kawamura G, Muto H, Matsuda A (2013) Low-temperature crystallization of TiO2 nanotube arrays via hot water treatment and their photocatalytic properties under visible-light irradiation. Mater Chem Phys 137(3):991–998

Liang H, Li X (2009) Effect of structure of anodic TiO2 nanotube arrays on photocatalytic activity for the degradation of 2, 3-dichlorophenol in aqueous solution. J Hazard Mater 162(2-3):1415–1422

Li G, Liu Z, Lu J, Wang L, Zhang Z (2009) Effect of calcination temperature on the morphology and surface properties of TiO2 nanotube arrays. Appl Surf Sci 255(16):7323–7328

Guo R, Wang C, Chen J, Wang J, Wang L, Liu W (2010) Field emission from TiO2/Ti nanotube arrays with different morphologies. Physica B 405(22):4682–4686

Si Y, Liu H, Li N, Zhong J, Li J, Ma D (2018) SDBS-assisted hydrothermal treatment of TiO2 with improved photocatalytic activity. Mater Lett 212:147–150

Jiao Z, Shang M, Liu J, Lu G, Wang X, Bi Y (2017) The charge transfer mechanism of Bi modified TiO2 nanotube arrays: TiO2 serving as a charge-transfer-bridge. Nano Energy 31:96–104

Mazieski P, Nadolna J, Lisowski W, Winiarski MJ, Gazda M, Nischk M, Klimczuk T, Zaleska-Medynska A (2017) Effect of irradiation intensity and initial pollutant concentration on gas phase photocatalytic activity of TiO2 nanotube arrays. Catal Today 284:19–26

Li M, Guo R, Hu C, Sun P, Pan W, Liu S, Sun X, Liu S, Liu J (2018) The enhanced resistance to K deactivation of Ce/TiO2 catalyst for NH3-SCR reaction by the modification with P. Appl Surf Sci 436:814–822

Yu SQ, Ling YH, Wang RG, Zhang J, Qin F, Zhang ZJ (2018) Constructing superhydrophobic WO3/TiO2 nanoflake surface beyond amorphous alloy against electrochemical corrosion on iron steel. Appl Surf Sci 436:527–535

Wu Q, Ouyang J, Xie K, Sun L, Wang M, Lin C (2012) Ultrasound-assisted synthesis and visible-light-driven photocatalytic activity of Fe-incorporated TiO2 nanotube array photocatalysts. J Hazard Mater 199-200:410–417

Jing L, Qu Y, Wang B, Li S, Jiang B, Yang L, Fu W, Fu H, Sun J (2006) Review of photoluminescence performance of nano-sized semiconductor materials and its relationships with photocatalytic activity. Sol Energy Mater Sol Cells 90:1773–1787

Liao W, Wang B, Liu Z (2017) Photoelectrochemical hydrogen production at peak efficiency over 10% via PbSe QDs/TiO2 nanotube array photoanodes. Int J Hydrog Energy 42(16):10962–10970

Wang Y, Li Z, Tian Y, Zhao W, Liu X, Yang J (2014) Facile method for fabricating silver-doped TiO2 nanotube arrays with enhanced photoelectrochemical property. Mater Lett 122:248–251

Li Y, Sasaki T, Shimizu Y, Koshizaki N (2008) Hexagonal-close-packed, hierarchical amorphous TiO2 nanocolumn arrays: transferability, enhanced photocatalytic activity, and superamphiphilicity without UV irradiation. J Am Chem Soc 130(44):14755–14762

Smith YR, Sarma B, Mohanty SK, Misra M (2012) Light-assisted anodized TiO2 nanotube arrays. ACS Appl Mater Interfaces 4(4):5883–5890

Yu D, Song Y, Zhu X, Yang C, Yang B, Xiao H (2013) Fabrication of bundle-free TiO2 nanotube arrays with wide open top via a modified two-step anodization process. Mater Lett 109:211–213

Peighambardoust N, Nasirpouri F (2013) Manipulating morphology, pore geometry and ordering degree of TiO2 nanotube arrays by anodic oxidation. Surf Coat Technol 235:727–734

Ochiai T, Fujishima A (2012) Photoelectrochemical properties of TiO2 photocatalyst and its applications for environmental purification. J Photochem Photobiol C 13(4):247–262

Hwang S, Petucci C, Raftery D (1998) In situ solid-state NMR studies of trichloroethylene photocatalysis: formation and characterization of surface-bound intermediates. J Am Chem Soc 120(18):4388–4397

Wang Q, Zheng Q, Jin R, Gao S, Yuan Q, Rong W, Wang R (2017) Photoelectrocatalytic removal of organic dyes and Cr (VI) ions using Ag3PO4 nanoparticles sensitized TiO2 nanotube arrays. Mater Chem Phys 199:209–215

Funding

This work is supported by the National Nature Science Foundation of China (No. 51404170), the Scientific Research Foundation of Tianjin University of Science & Technology (No. 10220), and the Innovation Team Program of Tianjin University of Science & Technology (No. 10117).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hao, L., Yan, J., Cheng, L. et al. Solar-responsive sole TiO2 nanotube arrays with high photocatalytic activity prepared by one-step anodic oxidation. J Solid State Electrochem 22, 3183–3190 (2018). https://doi.org/10.1007/s10008-018-4036-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-018-4036-6