Abstract

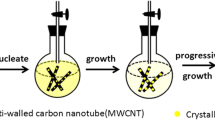

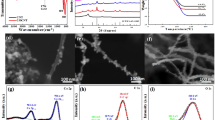

Porous multi-walled carbon nanotubes (PCNTs) with multiple mesopores structure are synthesized through activation of multi-walled carbon nanotubes (MWCNTs) by potassium hydroxide. The potassium hydroxide activation process results in a significantly enhanced specific surface area with numerous small pores. The as-obtained PCNTs are employed as the conductive matrix for sulfur in the sulfur cathode. Compared with the composite sulfur cathode based on the original MWCNTs, the sulfur-PCNTs cathode shows a significantly improved cycle performance and columbic efficiency. The reversible capacity is 530 mAh g−1 and columbic efficiency is 90 % after 100 cycles at a current density of 100 mA g−1. The improvement in the electrochemical performance for S-PCNT is mainly attributed to the enlarged surface area and the porous structure of the unique mesopores carbon nanotube host, which cannot only facilitate transport of electrons and Li+ ions, but also trap polysulfides, retard the shuttle effect during charge/discharge process.

Similar content being viewed by others

References

Tarascon JM, Armand M (2001) Nature 414:359–367

Whittingham MS (2004) Chem Rev 104:4271–4301

Ohzuku T, Brodd RJ (2007) J Power Sources 174:449–456

Ji X, Nazar LF (2010) J Mater Chem 20:9821–9826

Akridge JR, Mikhaylik YV, White N (2004) Solid State Ionics 175:243–245

Kolosnitsyn VS, Karaseva EV (2008) Russ J Electrochem 44:506–509

Marmorstein D, Yu TH, Striebel KA, McLarnon FR, Hou J, Cairns EJ (2000) J Power Sources 89:219–226

Yuan LX, Feng JK, Ai XP, Cao YL, Chen SL, Yang HX (2006) Electrochem Commun 8:610–614

Park CW, Ryu HS, Kim KW, Ahn JH, Lee JY, Ahn HJ (2007) J Power Sources 165:450–454

Aurbach D, Pollak E, Elazari R, Salitra G, Kelley CS, Affinito J (2009) J Electrochem Soc 156:A694–A702

Jung Y, Kim S (2007) Electrochem Commun 9:249–254

Sun J, Huang Y, Wang W, Yu Z, Wang A, Yuan K (2008) Electrochem Commun 10:930–933

He M, Yuan LX, Zhang WX, Hu XL, Huang YH (2011) J Phys Chem C 115:15703–15709

Han SC, Song MS, Lee H, Kim HS, Ahn HJ, Lee JY (2003) J Electrochem Soc 150:A889–A893

Zheng W, Liu YW, Hu XG, Zhang CF (2006) Electrochim Acta 51:1330–1335

Yuan L, Yuan H, Qiu X, Chen L, Zhu W (2009) J Power Sources 189:1141–1146

Chen J, Jia X, She Q, Wang C, Zhang Q, Zheng M, Dong Q (2010) Electrochim Acta 55:8062–8066

Wei W, Wang J, Zhou L, Yang J, Schumann B, NuLi Y (2011) Electrochem Commun 13:399–402

Choi YJ, Kim KW, Ahn HJ, Ahn JH (2008) J Alloy Compd 449:313–316

Wu F, Wu SX, Chen RJ, Chen S, Wang GQ (2009) Chin Chem Lett 20:1255–1258

Lai C, Gao XP, Zhang B, Yan TY, Zhou Z (2009) J Phys Chem C 113:4712–4716

Liang C, Dudney NJ, Howe JY (2009) Chem Mater 21:4724–4730

Ji X, Lee KT, Nazar LF (2009) Nature Mater 8:500–506

Jayaprakash N, Shen J, Moganty SS, Corona A, Archer LA (2011) Angew Chem Int Ed 50:1–6

Sun M, Zhang S, Jiang T, Zhang L, Yu J (2008) Electrochem Commun 10:1819–1822

Wu F, Wu S, Chen R, Chen J, Chen S (2010) Electrochem Solid-State Lett 13:A29–A31

Qiu L, Zhang S, Zhang L, Sun M, Wang W (2010) Electrochim Acta 55:4632–4636

He X, Ren J, Wang L, Pu W, Jiang C, Wan C (2009) J Power Sources 190:154–156

Niu JJ, Wang JN, Jiang Y, Su LF, Ma J (2007) Micropor Mesopor Mater 100:1–5

Xu B, Wu F, Su Y, Cao G, Chen S, Zhou Z, Yang Y (2008) Electrochim Acta 53:7730–7735

Sing KSW (1982) Pure Appl Chem 54:2201–2218

Shao CG, An HN, Wang X, Jia R, Zhao BJ, Ma Z, Li XY, Pan GQ, Li LB, Hong SM (2007) Macromolecules 40:9475–9481

Steijns M, Mars P (1976) J Colloid Interface Sci 57:175–180

Shinkarev VV, Fenelonov V, Kuvshinov GG (2003) Carbon 41:295–302

Liang X, Wen Z, Liu Y, Wu M, Jin J, Zhang H, Wu X (2011) J Power Sources 196:9839–9843

Barchasz C, Leprêtre JC, Alloin F, Patoux S (2012) J Power Sources 199:322–330

Chen J, Zhang Q, Shi Y, Qin L, Cao Y, Zheng M, Dong Q (2012) Phys Chem Chem Phys 14:5376–5382

Zhang SS, Read JA (2012) J Power Sources 200:77–82

Ji X, Evers S, Black R, Nazar LF (2011) Nature Commun 2:325. doi:10.1038/ncomms1293

Acknowledgments

This work was supported by the Natural Science Foundation of China (Grant Nos. 50825203, 21273087 and 20803042), the 863 program (Grant No. 2011AA11290 and 2011DFB70020), and the PCSIRT (Program for Changjiang Scholars and Innovative Research Team in University). In addition, the authors thank Analytical and Testing Center of Huazhong University of Science and Technology for providing SEM, XRD, TG/DTA, and Raman spectra measurement.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

He, M., Yuan, LX., Zhang, WX. et al. Porous carbon nanotubes improved sulfur composite cathode for lithium-sulfur battery. J Solid State Electrochem 17, 1641–1647 (2013). https://doi.org/10.1007/s10008-013-2023-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-013-2023-5