Abstract

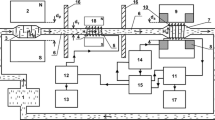

Online nuclear magnetic resonance (NMR) is an efficient fluid detection method for fluid flowing measurement. In our previous work, the velocity effects on the motion NMR measurement were studied and the velocity correction method was proposed. However, the flow state effects on NMR measurement is more complicated than motion velocity effects. Thus, the influence of flow state on NMR measurement is investigated. A multi-functional low-field and online NMR fluid analysis system is developed to realize the rapid measurement of one-dimensional and two-dimensional NMR relaxation times of fluids under slow laminar flow state.

Similar content being viewed by others

References

G.R. Coats, L.Z. Xiao, M.G. Prammer, NMR Logging Principles and Applications[M] (Gulf Professional Publishing, Houston, 1999)

F. Casanova, J. Perlo, B. Blümich, Single-Sided NMR (Springer, New York, 2011)

G.A. Matzkanin, in nondestructive characterization of materials. ed. by P. Holler, V. Hauck, C.O. Rund, R.E. Green (Springer, Berlin, 1989)

J.R. Suryan, Proc. Indian Acad. Sci. Sect. A 33, 107–111 (1951)

A. Caprihan, E. Fukushima, Phys. Rep. 198, 195–235 (1990)

J.R. Singer, Science 130(3389), 1652–1653 (2013)

F. Deng, L.Z. Xiao, H.B. Liu, T.L. An, M.Y. Wang, Z.F. Zhang, W. Xu, J.J. Cheng, Q.M. Xie, V. Anferov, Appl. Magn. Reson. 44, 1053–1065 (2013)

E.C. Bingham, Fluidity and Plasticity (McGraw-Hill Book Co., New York 1922)

N. Casson, in Rheolgy of Gisperse Systems, ed. by C.C. Mill (Pergamon Press, London, 1959), p. 84

W.H. Herschel, R. Bulkley, Proc. ASTM 26(II), 621–633 (1926)

R.E. Robertson, Soc. Pet. Eng. J. 16(1), 31–36 (1976)

G.R. Coats, L.Z. Xiao, M.G. Prammer, NMR Logging Principles and Applications [M] (Gulf Professional Publishing, Houston, 1999)

M.G. Prammer, J. Bouton, P. Masak. Magnetic resonance fluid analysis apparatus and method. US, 20020140425A1[P], 2002-10-03

B.S. Wu, L.Z. Xiao, X. Li, H.J. Yu, T.L. An, Pet. Sci. 9(1), 38–45 (2012)

H.J. Yu, L.Z. Xiao, X. Li, H.B. Liu, B.X. Guo, S. Anferov, V. Anferov, in 2011 IEEE International Conference on Signal Processing, Communication and computing, ICSPCC 2011. 6061656

F. Deng, L.Z. Xiao, W.L. Chen, H.B. Liu, G.Z. Liao, M.Y. Wang, Q.M. Xie, J. Magn. Reson. 247, 1–8 (2014)

F. Deng, L.Z. Xiao, G.Z. Liao, F.R. Zong, W.L. Chen, Appl. Magn. Reson. 45, 179–192 (2014)

Y.Q. Song, L. Venkataramanan, M.D. Hürlimann et al., T 1–T 2 correlation spectra obtained using a fast two-dimensional laplace inversion. J. Magn. Reson. 154, 261–268 (2002)

Acknowledgments

This work was supported by the National Science and Technology Major Project of the Ministry of Science and Technology of China (2016ZX05031-001) and National Scientific Instrument Development Project (21427812).

Author information

Authors and Affiliations

Corresponding author

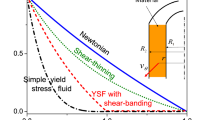

Appendix: The Flow Velocity Distributions in Circular Tube Under Different Flow Patterns

Appendix: The Flow Velocity Distributions in Circular Tube Under Different Flow Patterns

-

(1)

Bingham model [8].

Bingham mode velocity distribution function v(r)b:

where △P b is the Bingham mode fluid pressure difference at both sides of the pipe in the detection range:

L A is the length of antenna, R is the diameter of the sample tube, η p is the plastic viscosity of Bingham mode fluid:

θ 1, θ 2 represent the rheological coefficients is in rotary viscometer’s rotor with rotation rate N 1, N 2, respectively, τ 0 is the yield value:

the constant K τ is determined by rotary viscometer inner cylinder size and the characteristics of the spring, B b is the Bingham fluid correction coefficient:

R 0, R i represent the rotary viscometer’s outer and inner tube diameter, the flow core radius:

-

(2)

Ostwald-de Waele power law model.

Power law mode velocity distribution function v(r)p:

where △P p is the Power law mode fluid pressure difference at both sides of the pipe in the detection range:

n is the liquidity index:

K is the viscosity coefficient:

B p is Power law mode fluid correction coefficient:

-

(3)

Casson model [9].

Casson mode velocity distribution function v(r)c:

where △P c is the Casson mode fluid pressure difference at both sides of the pipe in the detection range:

η k is the plastic viscosity of Casson mode fluid:

K γ according to the rotary viscometer’s outer and inner tube diameter, B c is Casson mode fluid correction coefficient:

τ c is the Casson yield value:

-

(4)

Herschel–Bulkley model [10]

H-B mode velocity distribution function v(r)h:

make the coefficients a = θ 600 − θ 300, b = θ 6 − θ 3, a′ = θ 300 + θ 6, b′ = θ 600 + θ 3, c = θ 600 × θ 3, d = θ 300 × θ 6, here θ 3, θ 300, θ 600 represent the rheological coefficients is in rotary viscometer’s rotor with rotation rate N 3 = 3 r/min, N 300 = 300 r/min and N 600 = 600 r/min, respectively, △P h is the H-B mode fluid pressure difference at both sides of the pipe in the detection range:

yield value τ 0:

θ x = τ x /0.511, the coefficient C 1:

n is the liquidity index:

K is the viscosity coefficient:

coefficients C 2:

the flow core radius r m :

-

(5)

Robertson–Stiff model [11]

R-S mode velocity distribution function v(r)l:

where, △P l is the R-S mode fluid pressure difference at both sides of the pipe in the detection range:

the viscosity coefficients A′:

the liquidity index B′:

the shear rate correction value C′:

N x according to the θ x , N 1 and N 2:

R-S yield value τ x :

Rights and permissions

About this article

Cite this article

Deng, F., Xiao, L., Wang, M. et al. Online NMR Flowing Fluid Measurements. Appl Magn Reson 47, 1239–1253 (2016). https://doi.org/10.1007/s00723-016-0832-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00723-016-0832-2