Abstract

A Brønsted acid-catalyzed selective arene-ynamide cyclization is described. This reaction proceeds via a keteniminium intermediate and enables the preparation of seven-membered ring enamide products. Mechanistic studies uncover an unusual product inhibition behavior.

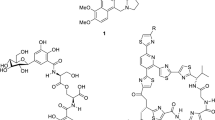

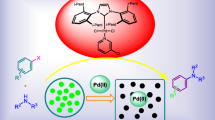

Graphical abstract

Similar content being viewed by others

Introduction

Enamides are found as structural elements in biologically relevant natural compounds and constitute useful intermediates in organic synthesis [1,2,3,4]. Accordingly, the synthesis of enamides has been the subject of considerable investigation in the past decades. However, the preparation of cyclic enamides remains rare [6], in particular when medium-ring derivatives are targeted [5, 6].

As part of our research, we have made extensive use of ynamides as versatile reagents for a range of electrophile-triggered transformations [7,8,9,10,11,12,13,14,15,16,17,18]. Recently, we developed an efficient approach to prepare α,β-disubstituted enamides via the addition of dialkylzinc reagents to a Bronsted acid-activated ynamide (in the form of a keteniminium/enamide triflate intermediate) [18]. During this study, we found that ynamide 1a, carrying a phenyl substituent at the end of a three-carbon chain, did not afford the desired product 3 (Fig. 1b). In pioneering work on ynamide cyclizations, Hsung et al. reported an efficient acid-catalyzed process that delivers five- or six-membered ring enamide products as shown in Fig. 1a [6, 19,20,21,22,23,24,25]. Surprisingly, the formation of seven-membered ring enamides was not included in that report, which motivated us to study this reaction in more detail. Herein, we wish to report our observations in this study and our understanding of the reaction mechanism.

Results and discussion

At the outset, we focused on the readily available ynamide 1a to screen a variety of reaction conditions. When compound 1a is treated with a full equivalent (1.0 equiv.) of TfOH in DCM, the desired cyclization product is formed in good chemical yield after only 5 min (Table 1, entry 1). Aiming to employ catalytic amounts of TfOH we found that, when 5–10 mol% (0.05–0.1 equiv.) TfOH was used, the yield of product 2a dropped precipitously (entries 2–5). A consistent trend was observed for even slightly larger amounts of TfOH all the way up to 50 mol% (0.5 equiv.), where no more than 45% of product could be detected (entries 6–10).

The use of Tf2NH did not lead to better results (entries 11, 12) and we eventually acknowledged the need for a full equivalent of TfOH to achieve full conversion. Under those conditions (entry 14), a reaction time of 1 h proved ideal and allowed the obtention of 81% isolated yield of 1a.

With suitable reaction conditions in hand, a number of ynamides were prepared and screened (Table 2). A para-Me substrate 1b was also a suitable precursor for this cyclization. Disappointingly, the higher homologs 1c and 1d did not lead to the products of cyclization (8- and 9-membered ring products 2c/2d). In these cases, only starting material was recovered.

Interestingly, the use of an oxygen-tethered substrate 1e led cleanly to the formation of acryloyl imide 2e in 81% yield. We believe that this is the result of a fragmentation process, as outlined in Fig. 2.

The experiments described herein, in particular those in Table 1, reinforce the notion that stoichiometric amounts of TfOH are needed in order to obtain the enamide product. This is at odds with the theoretical mechanism for this cyclization (Fig. 1b), whereby the Friedel–Crafts-like attack of the aromatic onto the keteniminium presupposes transient loss of aromaticity which is later regained by loss of a proton. Reevaluation of the data presented in Table 1 also shows a direct proportionality between conversion/yield of product and catalyst loading, clearly suggesting that catalyst inhibition beyond a single turnover is taking place [19].

To obtain further insight on this, 1H NMR studies were carried out in Fig. 3. When 1a was treated with TfOH in DCM, formation of the desired cyclization product 2a was observed swiftly (within 15 min). However, upon extension of the reaction time, the product 2a was slowly converted to another compound. We assigned this new compound as iminium 4a, the product of protonation of the enamide double bond.

As shown in Fig. 4, when pure enamide was treated with TfOH for 5 min, the formation of compound 4 was also observed by NMR (spectra 1, 2, and 3). After quenching with water, we can observe the formation of ketone (spectra 4 and 5).

Taking all this information into account (Fig. 5), it becomes apparent when catalytic amounts of TfOH were used, the initially formed 2a further reacts with TfOH to form compound 4a. This ultimately results in consumption of all available TfOH. With no addditional acidic catalyst to promote the cyclization of 1a, conversion of 2a then naturally stopped at a level of actual loading of TfOH.

Conclusion

We have reported herein a Brønsted acid-catalyzed arene-ynamide cyclization for the formation of a seven-membered ring enamide. Through mechanistic studies, an unusual product inhibition behavior was observed which mandated the use of stoichiometric amounts of TfOH.

Experimental

All glassware was dried before use. All solvents were used in p.a. quality. All reagents were used as received from commercial suppliers unless otherwise stated. Reaction progress was monitored using TLC on aluminum sheets coated with silica gel 60 with 0.2 mm thickness (Pre-coated TLC-sheets ALUGRAM® Xtra SIL G/UV254). Visualization was achieved by UV light (254 nm and 363 nm) and/or by treatment with potassium manganite(VII) and heat. CC was performed using silica gel 60 (230–400 Mesh, MERCK AND CO.). All 1H NMR and 13C NMR spectra were recorded on BRUKER AVIII-400 in CDCl3. Chemical shifts (δ) were given in “parts per million” (ppm), referenced to the peak of TMS (δ = 0.00 ppm), using the solvent as internal standard (1H: δ(CDCl3) = 7.26 ppm; 13C: δ(CDCl3) = 77.16 ppm [26]). Coupling constants (J) were given in Hz. Spectroscopy splitting patterns were designated as singlet (s), doublet (d), triplet (t), quartet (q), pentet (p), multiplet (m), or combinations of that. MS were obtained using a BRUKER maXis spectrometer with ESI and the main signals were given in m/z units. IR were recorded on a BRUKER VERTEX FT-IR spectrometer. The following computer programs were used: MestReNova from Mestrelab Research and ChemDraw from PerkinElmer.

General procedure of synthesis of ynamides

In a 250 cm3 two-neck round-bottom flask equipped with a stir-bar, CuCl2 (0.2 equiv.), nitrogen nucleophile (5 equiv.), and Na2CO3 (2 equiv.) were combined. The reaction flask was purged with oxygen gas. A solution of pyridine (2 equiv.) in dry toluene (0.06 M) was added to the reaction flask and stirred at 70 °C. After 0.5 h, a solution of the respective alkyne (1.0 equiv.) in dry toluene (0.033 M) was added to the flask over 4 h using a syringe pump. After addition of alkyne/toluene solution, the reaction mixture was allowed to stir at 70 °C overnight. After cooling to r.t., the crude mixture was concentrated under reduced pressure. The residue was purified by column chromatography on silica gel.

3-(5-Phenylpent-1-yn-1-yl)oxazolidin-2-one (1a, C14H15NO2)

According to the general procedure, the ynamide 1a was isolated after purification by column chromatography (pentane/EE = 5:1–1:1) as a yellow oil (1555 mg, 6.8 mmol, 68%). 1H NMR (400 MHz, CDCl3): δ = 7.30 (t, 2H), 7.21 (dd, J = 9.9, 4.1 Hz, 3H), 4.43 (t, 2H), 3.89 (t, 1H), 2.75 (m, 2H), 2.35 (t, J = 7.1 Hz, 2H), 1.88 (p, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 141.6, 128.7, 128.5, 126.0, 70.9, 62.9, 47.2, 34.9, 30.4, 18.0 ppm; IR: \(\bar{\nu }\) = 3060, 3026, 2924, 2861, 2270, 1766, 1603, 1479, 1454, 1415, 1302, 1207, 1113, 1035, 972, 748, 701 cm−1; HRMS (ESI): m/z calculated for [M]+ 229.1103, found 229.1093.

3-(5-Phenylpent-1-yn-1-yl)oxazolidin-2-one (1b, C15H17NO2)

According to the general procedure, 1b was isolated after purification by column chromatography [pentane/EE = 5:1–1:1] as orange crystals (0.71 g, 2.9 mmol, 33%). 1H NMR (600 MHz, CDCl3): δ = 7.11–7.06 (m, 4H), 4.43–4.39 (m, 2H), 3.89–3.85 (m, 2H), 2.68 (t, 2H), 2.34–2.29 (m, 5H), 1.87–1.80 (m, 2H) ppm; 13C NMR (151 MHz, CDCl3): δ = 156.7, 138.6, 135.5, 129.2, 128.5, 71.0, 70.6, 62.9, 47.2, 34.5, 30.6, 21.1, 18.0 ppm; IR: \(\bar{\nu }\) = 2923, 2860, 2271, 1767, 1515, 1479, 1415, 1302, 1206, 1112, 1036, 806, 750 cm−1; HRMS (ESI): m/z calculated for [M+Na]+ 266.1157, found 266.1153.

3-(6-Phenylhex-1-yn-1-yl)oxazolidin-2-one (1c, C15H17NO2)

According to the general procedure, 1c was isolated after purification by column chromatography (pentane/EE = 5:1–1:1) as a yellow oil (43 mg, 0.19 mmol, 9%). Starting material was recovered as a yellow oil (211 mg, 1.3 mmol, 67%). 1H NMR (400 MHz, CDCl3): δ = 7.28 (ddd, J = 7.2, 3.5, 1.4 Hz, 2H), 7.17 (m, 3H), 4.40 (dt, 2H), 3.85 (dt, 2H), 2.63 (t, J = 7.6 Hz, 2H), 2.34 (t, J = 7.1 Hz, 2H), 1.73 (m, 2H), 1.57 (m, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 156.8, 142.4, 128.6, 128.4, 125.9, 71.1, 70.3, 62.9, 60.6, 47.2, 35.5, 31.1, 30.7, 28.4, 18.5 ppm; IR: \(\bar{\nu }\) = 2925, 2855, 2270, 1602, 1479, 1454, 1414, 1302, 1204, 1112, 1035, 973, 748, 700, 618 cm−1; HRMS (ESI): m/z calculated for [M]+ 243.1259, found 243.1252.

3-(7-Phenylhept-1-yn-1-yl)oxazolidin-2-one (1d, C16H19NO2)

According to the general procedure, 1d was isolated after purification by column chromatography (pentane/EE = 5:1–1:1) as a yellow oil (197 mg, 0.77 mmol, 44%). Starting material was recovered as a yellow oil (136 mg, 0.79 mmol, 45%). 1H NMR (400 MHz, CDCl3): δ = 7.27 (dd, J = 10.6, 5.7 Hz, 3H), 7.17(m, 2H), 4.40 (dd, J = 8.6, 7.4 Hz, 2H), 3.84 (dd, J = 8.6, 7.4 Hz, 2H), 2.62 (t, 2H), 2.30 (t, J = 7.2 Hz, 2H), 1.63 (dt, J = 15.4, 7.7 Hz, 2H), 1.56 (dt, 2H), 1.43 (m, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 156.8, 142.7, 128.6, 128.4, 125.8, 71.3, 70.3, 62.9, 47.2, 35.9, 31.1, 28.8, 28.6, 18.5 ppm; IR: \(\bar{\nu }\) = 3060, 3025, 2931, 2857, 2266, 1769, 1603, 1480, 1454, 1415, 1302, 1264, 1206, 1113, 1036, 747, 701 cm−1; HRMS (ESI): m/z calculated for [M]+ 257.1416, found 257.1412.

General procedure of cyclization of ynamide

The respective ynamide (0.20 mmol, 1.0 equiv.) was dissolved in dry DCM under inert atmosphere at 0 °C. Triflic acid (0.20 mmol, 1.0 equiv.) was added dropwise using a microsyringe and stirred for 1 h. The reaction was quenched by the addition of a sat. NH4Cl solution. The reaction mixture was extracted with DCM and the combined organic phases were dried over MgSO4 and concentrated under reduced pressure. The residue was purified by column chromatography on silica gel.

3-(6,7-Dihydro-5H-benzo[g]annulen-9-yl)oxazolidin-2-one (2a, C14H15NO2)

According to the general procedure, 69 mg 1a (0.30 mmol, 1.0 equiv.) and 45 mg triflic acid (0.30 mmol, 1.0 equiv.) were reacted in 3 cm3 DCM and the corresponding cyclization product 2a was isolated after purification by column chromatography (pentane/EE = 3:1–1:1) as a white solid (56 mg, 0.24 mmol, 81%). The ketone side product was isolated as white solid (7 mg, 0.03 mmol, 10%). 1H NMR (400 MHz, CDCl3): δ = 7.24 (m, 5H), 6.25 (t, J = 7.1 Hz, 1H), 4.39 (ddd, J = 8.1, 7.2, 2.7 Hz, 2H), 3.68 (t, 2H), 2.66 (t, J = 6.8 Hz, 2H), 2.15 (p, 2H), 2.00 (p, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 129.5, 128.2, 126.6, 126.4, 124.3, 61.8, 46.7, 34.7, 32.6, 24.1 ppm; IR: \(\bar{\nu }\) = 2928, 2857, 1751, 1634, 1481, 1452, 1112, 1086, 1038, 898, 773, 756, 730, 702, 607 cm−1; HRMS (ESI): m/z calculated for: [M]+ 229.1103, found 229.1094.

3-(3-Methyl-6,7-dihydro-5H-benzo [7] annulen-9-yl)oxazolidin-2-one (2b, C15H17NO2)

According to the general procedure, 2b was isolated as a white solid (109 mg, 0.446 mmol, 90%). The ketone side product 8 was isolated as a colorless oil (0.8 mg, 0.005 mmol, 1%). 1H NMR (600 MHz, CDCl3): δ = 7.14–7.00 (m, 4H), 6.23 (t, J = 7.2 Hz, 1H), 4.41–4.38 (m, 2H), 3.70–3.65 (m, 2H), 2), 2.61 (t, J = 6.9 Hz, 2H), 2.33 (s, 3H), 2.11 (p, J = 7.2 Hz, 2H), 1.98 (q, J = 7.2 Hz, 2H) ppm; 13C NMR (151 MHz, CDCl3): δ = 156.9, 139.3, 135.8, 135.4, 134.8, 130.7, 129.4, 129.0, 127.0, 124.4 ppm; IR: \(\bar{\nu }\) = 2923, 2855, 1743, 1632, 1480, 1447, 1397, 1364, 1287, 1258, 1221, 1147, 1119, 1083, 1066, 1036, 976, 923, 825, 794, 757, 732, 683 cm−1; HRMS (ESI): m/z calculated for [M+H]+ 244.1338, found 244.1335.

3-Acryloyloxazolidin-2-one (2e, C6H7NO3)

According to the general procedure, 46 mg 1e (0.2 mmol, 1.0 equiv.) and 30 mg triflic acid (0.2 mmol, 1.0 equiv.) were reacted in 2 cm3 DCM and the amide 2e was isolated after purification by column chromatography (pentane/EE = 3:1–1:1) as a white solid (25 mg, 0.18 mmol, 89%). 1H NMR (400 MHz, CDCl3): δ = 7.50 (dd, 1H), 6.56 (dd, J = 17.0, 1.8 Hz, 1H), 5.90 (dd, J = 10.5, 1.8 Hz, 1H), 4.44 (t, 2H), 4.09 (t, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 165.2, 153.5, 131.9, 127.1, 62.3, 42.8 ppm; IR: \(\bar{\nu }\) = 1775, 1717, 1687, 1412, 1389, 1327, 1264, 1118, 1066, 1040, 1014, 732, 702 cm−1; HRMS (ESI): m/z calculated for [M]+ 141.0426, found 141.0417.

References

Yet L (2003) Chem Rev 103:4283

Shen R, Lin CT, Bowman EJ, Bowman BJ, Porco JA (2003) J Am Chem Soc 125:7889

Lin S, Yang ZQ, Kwok BHB, Koldobskiy M, Crews CM, Danishefsky SJ (2004) J Am Chem Soc 126:6347

Martín MJ, Coello L, Fernández R, Reyes F, Rodríguez A, Murcia C, Garranzo M, Mateo C, Sánchez-Sancho F, Bueno S, de Eguilior C, Francesch A, Munt S, Cuevas C (2013) J Am Chem Soc 135:10164

Tian PP, Cai SH, Liang QJ, Zhou XY, Xu YH, Loh TP (2015) Org Lett 17:1636

Zhang YS, Hsung RP, Zhang XJ, Huang J, Slafer BW, Davis A (2005) Org Lett 7:1047

DeKorver KA, Li H, Lohse AG, Hayashi R, Lu Z, Zhang Y, Hsung RP (2010) Chem Rev 110:5064

Evano G, Blanchard N, Compain G, Coste A, Demmer CS, Gati W, Guissart C, Heimburger J, Henry N, Jouvin K, Karthikeyan G, Laouiti A, Lecomte M, Martin-Mingot A, Métayer B, Michelet B, Nitelet A, Theunissen C, Thibaudeau S, Wang J, Zarca M, Zhang C (2016) Chem Lett 45:574

Evano G, Theunissen C, Lecomte M (2015) Aldrichim Acta 48:59

Evano G, Jouvin K, Coste A (2013) Synthesis 45:17

Peng B, Huang XL, Xie LG, Maulide N (2014) Angew Chem Int Ed 53:8718

Xie LG, Niyomchon S, Mota AJ, Gonzalez L, Maulide N (2016) Nat Comm 7:10914

Kaldre D, Klose I, Maulide N (2018) Science 361:664

Maryasin B, Kaldre D, Galaverna R, Klose I, Ruider S, Drescher M, Kählig H, González L, Eberlin M, Jurberg I, Maulide N (2018) Chem Sci 9:4124

Pinto A, Kaiser D, Maryasin B, Di Mauro G, González L, Maulide N (2018) Chem Eur J 24:2515

Kaldre D, Maryasin B, Kaiser D, Gajsek O, González L, Maulide N (2017) Angew Chem Int Ed 56:2212

Xie LG, Shaaban S, Chen X, Maulide N (2016) Angew Chem Int Ed 55:12864

Baldassari LL, de la Torre A, Li J, Lüdtke DS, Maulide N (2017) Angew Chem Int Ed 56:15723

Terada M, Sorimachi K (2007) J Am Chem Soc 129:292

Li L, Chen XM, Wang ZS, Zhou B, Liu X, Lu X, Ye LW (2017) ACS Catal 7:4004

Nayak S, Ghosh N, Prabagar B, Sahoo AK (2015) Org Lett 17:5662

Yamaoka Y, Yoshida T, Shinozaki M, Yamada KI, Takasu K (2015) J Org Chem 80:957

Theunissen C, Métayer B, Henry N, Compain G, Marrot J, Martin-Mingot A, Thibaudeau S, Evano G (2014) J Am Chem Soc 136:12528

Sabbasani VR, Lee H, Xie P, Xia Y, Lee D (2017) Chem Eur J 16:8161

Lecomte M, Evano G (2016) Angew Chem Int Ed 55:4547

Gottlieb HE, Kotlyar V, Nudelman A (1997) J Org Chem 62:7512

Acknowledgements

Open access funding provided by Austrian Science Fund (FWF). We are grateful to the ERC (CoG VINCAT) and the FWF (P30226) for financial support. Generous continued support of our research programs by the University of Vienna is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Brutiu, B.R., Bubeneck, W.A., Cvetkovic, O. et al. On the formation of seven-membered rings by arene-ynamide cyclization. Monatsh Chem 150, 3–10 (2019). https://doi.org/10.1007/s00706-018-2320-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-018-2320-x