Abstract

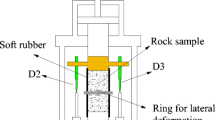

In deep shale gas reservoir exploration, elastoplastic embedment plays an increasingly important role in analyses of the conductivity of fracture networks because it is affected by high temperature, high in-situ stress. To obtain a full understanding of proppant embedding behavior, an analytical model of the embedment depth of a single spherical proppant was developed based on the Drucker–Prager (D–P) yield criterion and shale elastoplastic mechanical behavior. Shale indentation tests with rigid balls with diameters of 0.8 mm and 1.0 mm were conducted to validate the reliability of the theoretical model. Compared with the Hertz, Thornton and non-linear models, the new model developed in this paper was in better agreement with embedment experimental data. Each parameter of the new model has clear physical meaning and can be obtained by a series of triaxial compression tests. An Analysis of Variance (ANOVA) method was applied to discuss the sensitivity of the model to the parameters, and the results showed that the strength parameters α and Y contributed the most to, and had nonlinear effects on, the proppant embedment depth.

Highlights

-

According to the shale mechanical properties, the contact area between a single spherical particle and a semi-infinite space can be divided into elastic, strain hardening and fully plastic region approximately.

-

An analytical elastoplastic embedment depth model for a single rigid spherical particle was developed based on the Drucker-Prager yield criterion and total strain theory.

-

The yielding parameters have a dominant and nonlinear effects on the proppant embedment depth.

-

It is more appreciated that applying a suitable yield criterion which can accurately describe the yielding process of rock-like materials to discuss the interaction between proppant and shale.

Similar content being viewed by others

Data Availability

All data analyzed during this work are included in this published paper and are available from the corresponding author on reasonable request.

Abbreviations

- r :

-

A radial distance measured from the center of the contact surface

- a :

-

Contact radius

- \(p_m\) :

-

The maximum contact pressure at the center of the contact area

- R :

-

Radius of proppant particle

- δ, δ y, δ pp :

-

Proppant embedment depth at the centerline, the depth at the initial yield state, and the depth at the initial state of the ultimate strength stage

- \(\sigma_r\), \(\sigma_\theta\), \(\sigma_z\) :

-

Normal stresses in radial, circumferential and vertical directions, respectively

- \(\tau_{rz}\), \(\tau_{r\theta }\),\(\tau_{z\theta }\) :

-

Corresponding shear stresses

- I 1, J 2 :

-

Spherical tensor invariant and the second deviator tensor invariant, respectively

- α, Y :

-

Material yield parameters

- \(\sigma_{eq}\) :

-

Equivalent stress under the condition of the D–P yield criterion

- \(\xi\), \(\xi_0\) :

-

Dimensionless embedment depth and initial yield dimensionless embedment depth, respectively

- E, v :

-

Young’s modulus, and Poisson’s ratio, respectively

- \(p_y\) :

-

Initial yield contact pressure

- a y, a p ,a pp :

-

Initial yield contact radius, elastoplastic strengthening region radius, and fully plastic region radius, respectively

- \(\beta\), \(\beta_{py}\), d :

-

Material parameters

- \(\sigma_y\) :

-

Initial yield strength of shale

- \(\sigma_i\), \(\varepsilon_i\) :

-

Equivalent stress and equivalent strain, respectively

- \(\varepsilon^*\) :

-

Virtual strain

- F, F y :

-

Contact force and initial yield contact force, respectively

- C v :

-

\(p_m {/}\sigma_{eq}\)

References

Alramahi B, Sundberg MI (2012) Proppant embedment and conductivity of hydraulic fractures in shales. 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, Illinois

Bandara KMAS, Ranjith PG, Rathnaweera TD (2019) Improved understanding of proppant embedment behavior under reservoir conditions: a review study. Powder Technol 352:170–192

Big-Alabo A, Harrison P, Cartmell MP (2015) Contact model for elastoplastic analysis of half-space indentation by a spherical impactor. Comput Struct 151:20–29

Brake MR (2012) An analytical elastic-perfectly plastic contact model. Int J Solids Struct 49(22):3129–3141

Brizmer V, Kligerman Y, Etsion I (2006) The effect of contact conditions and material properties on the elasticity terminus of a spherical contact. Int J Solids Struct 43(18–19):5736–5749

Chen D, Ye Z, Pan Z, Zhou Y, Zhang J (2017) A permeability model for the hydraulic fracture filled with proppant packs under combined effect of compaction and embedment. J Petrol Sci Eng 149:428–435

Chen M, Zhang S, Liu M, Ma X, Zou Y, Zhou T, Li N, Li S (2018) Calculation method of proppant embedment depth in hydraulic fracturing. Petrol Explor Dev 45(1):159–166

Cui A, Glover K, Wust R (2014) Elastic and plastic mechanical properties of liquids-rich unconventional shales and their implications for hydraulic fracturing and proppant embedment: a case study of the Nordegg Member in Alberta, Canada. Us Rock Mechanics/geomechanics Symposium

Ding X, Zhang F, Chen N, Zhang Y (2021) Numerical modeling of proppant embedment in viscoelastic formations with the fractional Maxwell model. Acs Omega 6(31):20398–20407

Elsarawy AM, Nasr-El-Din HA (2019) A new method to measure propped fracture width and proppant porosity in shale fractures. J Petrol Sci Eng 181:106162

Fan M, Li Z, Han Y, Teng Y, Chen C (2020) Experimental and numerical investigations of the role of proppant embedment on fracture conductivity in narrow fractures. SPE J 26(1):324–341

Fuss T, Shi J, Bottiglieri S, Herskovits R (2016) Evaluation of sand and ceramic proppant performance under thin layer/monolayer conditions of unconventional hydraulic fractures, SPE Low Perm Symposium, Denver, Colorado, USA.

Ghaednia H, Mifflin G, Lunia P, O’Neill EO, Brake MRW (2020) Strain hardening from elastic-perfectly plastic to perfectly elastic indentation single asperity contact. Front Mech Eng-Switz 6:60

Guo J, He S, Deng Y, Zhao Z (2015) New stress and initiation model of hydraulic fracturing based on nonlinear constitutive equation. J Nat Gas Sci Eng 27:666–675

Guo J, Wang J, Liu Y, Chen Z, Zhu H (2017) Analytical analysis of fracture conductivity for sparse distribution of proppant packs. J Geophys Eng 14(3):599–610

Guo J, Zhao Z, Lu Q, Yin C, Chen C (2021) Research progress in key mechanical theories of deep shale network fracturing (in chinese). Nat Gas Indus 41(1):102–117

Guo J, Chen X (2022). Pressure dependence of elastic wave velocities of unconsolidated cemented sands. Geophysics 87(4): MR161–MR175

He B, Xie L, Li F, Zhao P, Zhang Y (2017) Anisotropic mechanism and characteristics of deformation and failure of Longmaxi shale (in Chinese). Scientia Sinica-Physica Mechanica & Astronomica 47(11):114611

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

Larsson PL, Olsson E (2016) Elastic-plastic contact between hard metal particles. Key Eng Mater 681:86–99

Li L, Gu J (2009) An analytical solution for the unloading in spherical indentation of elastic–plastic solids. Int J Eng Sci 47(3):452–462

Li LY, Wu CY, Thornton C (2002) A theoretical model for the contact of elastoplastic bodies. J Mech Eng Sci 216(4):421–431

Li K, Gao Y, Lyu Y, Wang M (2015) New mathematical models for calculating proppant embedment and fracture conductivity. SPE J 20(3):496–507

Liang F, Han YH, Liu HH, Saini R, Rueda JI (2020) An improved hydraulic fracturing treatment for stimulating tight organic-rich carbonate reservoirs. SPE J 25(3):632–645

Maslowski M, Kasza P, Czupski M, Wilk K, Moska R (2019) Studies of fracture damage caused by the proppant embedment phenomenon in shale rock. Appl Sci-Basel 9(11):2190

Masowski M, Labus M (2021) Preliminary studies on the proppant embedment in baltic basin shale rock. Rock Mech Rock Eng 54(3):2233–2248

Mueller M, Amro M (2015) Indentation hardness for improved proppant embedment prediction in shale formations. SPE European Formation Damage Conference and Exhibition, Budapest, Hungary June 3–5

Olsson E, Larsson PL (2016) A unified model for the contact behaviour between equal and dissimilar elastic–plastic spherical bodies. Int J Solids Struct 81:23–32

Rybacki E, Reinicke A, Meier T, Makasi M, Dresen G (2015) What controls the mechanical properties of shale rocks? – Part I: Strength and Young’s modulus. J Petrol Sci Eng 2015:S0920410515301546

Rybacki E, Meier T, Dresen G (2016) What controls the mechanical properties of shale rocks?—Part II: brittleness. J Petrol Sci Eng 144:39–58

Shi F, Wang X, Liu C, Liu H, Wu H (2018) An XFEM-based numerical model to calculate conductivity of propped fracture considering proppant transport, embedment and crushing. J Petrol Sci Eng 167:615–626

Shi F (2011) Dynamic analysis and modeling to elastic-plastic collision between two spheres (in Chinese), Lanzhou university, Lanzhou

Tang Y, Ranjith PG (2018) An experimental and analytical study of the effects of shear displacement, fluid type, joint roughness, shear strength, friction angle and dilation angle on proppant embedment development in tight gas sandstone reservoirs. Int J Rock Mech Min Sci 107:94–109

Thornton C (1997) Coefficient of restitution for collinear collisions of elastic perfectly plastic spheres. J Appl Mech 64(2):383–386

Voltolini M, Rutqvist J, Kneafsey T (2021) Coupling dynamic in situ X-ray micro-imaging and indentation: A novel approach to evaluate micromechanics applied to oil shale. Fuel 300:120987

Wang Y, Xu M, Yang C, Lu M, Meng J, Wang Z, Wang M (2020) Effects of elastoplastic strengthening of gravel soil on rockfall impact force and penetration depth. Int J Impact Eng 136:103411

Yu W, Blanchard JP (1996) An elastic-plastic indentation model and its solutions. J Mater Res 11(9):2358–2367

Zhang Y, Li TY, Xie LZ, Yang ZP, Li RY (2017) Shale lamina thickness study based on micro-scale image processing of thin sections. J Nat Gas Sci Eng 46:817–829

Zhang Y, Xie L, Zhao P, He B (2020) Study of the quantitative effect of the depositional layering tendency of inclusions on the elastic anisotropy of shale based on two-step homogenization. Geophys J Int 220(1):174–189

Zhao B, Zhang S, Wang QF, Zhang Q, Wang P (2015) Loading and unloading of a power-law hardening spherical contact under stick contact condition. Int J Mech Sci 94–95:20–26

Zou Y, Ma X, Zhang S, Zhou T, Ehlig-Economides C, Li H (2015) The origins of low-fracture conductivity in soft shale formations: an experimental study. Energy Technol 3(12):1233–1242

Acknowledgements

This work was financially supported by the National Natural Science Foundation (No. 11872258), and Creative Project of Engineering Research Center of Alternative Energy Materials & Devices, Ministry of Education, Sichuan University (Grant No. AEMD 202206). We would like to thank our colleagues for their kind efforts and valuable comments in improving this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, B., Xie, L., Che, Y. et al. A Simplified Analytical Elastoplastic Embedment Depth Model of Proppant Based on the Drucker–Prager Yield Criterion. Rock Mech Rock Eng 56, 6207–6217 (2023). https://doi.org/10.1007/s00603-023-03394-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03394-0