Abstract

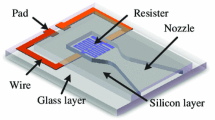

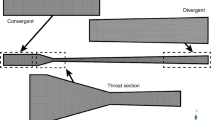

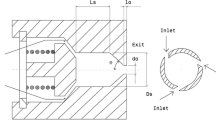

Microthruster has been playing significant role in micropropulsion system, of which micronozzle is the key component. In the present work, the geometric parameters of a typical micronozzle on a cold gas microthruster are first optimized using numerical univariate and orthogonal analysis combined with confirmation of thrust experiments. A 2 Dimension (2D) univariate numerical simulation, with only one geometric parameter varying within a large range during a simulation, is used to fully discuss the eight structural parameters of the proposed micronozzle. According to the effect of each parameter on the micronozzle performance, five critical factors, including half expansion angle θ out , expansion ratio W out /W t , throat width W t , throat radius of curvature R t , Inlet width W in and their corresponding proper levels range are selected. Then, a 2D orthogonal numerical simulation analysis is conducted utilizing an L 16(45) orthogonal table with the selected factors and levels. By analyzing the selected factors and levels simultaneously by range analysis method, the orders of significance of different factors are sorted and the optimum structural parameters are selected. The optimum result achieved in this study is identified as θ out of 15°, W t of 200 μm, W out /W t of 7, R t of 20 μm and W in of 4000 μm. Then, a 3 Dimension (3D) numerical simulation is conducted to predict and analyze the performance of the optimum microthruster when inlet pressure varies in three different values. When inlet pressure is 0.918 bar and temperature is 300 K, 3D simulation result shows that the microthruster using nitrogen as propellant can generate a thrust of 2.23 mN and efficiency of 72.14%. At last, an optimum cold gas microthruster adopting nitrogen gas as propellant is fabricated and tested. Experiment is conducted in three different inlet pressure. Results show that experimental values and simulation values are in agreement, which verifies the correctness of the simulation model. Under the inlet pressure of 0.918 bar and temperature of 300 K, the optimum microthruster can produce a thrust of 1.41 mN and efficiency of 52.84% when outlet pressure is set as 1000 Pa.

Similar content being viewed by others

References

Anderson DJ (2003) Modern compressible flow: with historical perspective. McGraw-Hill Book Company, Boston

Bayt (1999) Analysis, fabrication and testing of a MEMS-based micropropulsion system. Dissertation, Massachusetts Institute of Technology

Cheah KH, Chin JK (2011) Performance improvement on MEMS micropropulsion system through a novel two-depth micronozzle design. Acta Astronaut 69(1):59–70

Chen CC, Liu CW, Kan HC et al (2010) Simulation and experiment research on vaporizing liquid micro-thruster. Sens Actuators A 157:140–149

Chen H, Zhang Y, Zhang M et al (2013) Performance prediction of conical nozzle using Navier-Stokes computation. 49th AIAA/ASME/SAE/ASEE joint propulsion conference. doi:10.2514/6.2013-3733

Gagne KR, Hitt DL, McDevitt MR (2016) Development of an additively manufactured microthruster for nanosatellite applications. 54th AIAA aerospace sciences meeting, p 0963

Jon A, Donghoon L (2013) Computational prediction of the thrust characteristics of a small thruster at low pressure condition. 49th AIAA/ASME/SAE/ASEE joint propulsion conference. doi:10.2514/6.2013-3908

Juergen M (1997) Thruster options for microspacecraft—A review and evaluation of existing hardware and emerging technologies. 33rd joint propulsion conference and exhibit. doi:10.2514/6.1997-3058

Karthikeyan K, Chou SK, Khoong LE, Tan YM, Lu CW, Yang WM (2012) Low temperature co-fired ceramic vaporizing liquid microthruster for microspacecraft applications. Appl Energy 97:577–583

Kean How C, Kai Seng K, Choon Lai C, Jit Kai C (2011) Progress on development of Al2O3-SiO2 ceramic MEMS-based monopropellant micropropulsion system. 47th AIAA/ASME/SAE/ASEE joint propulsion conference & exhibit, doi:10.2514/6.2011-5923

Kim I, Lee JW, Choi MK, Kwon S (2011) Optimum nozzle angle of a micro solid-propellant thruster. Nanoscale Microscale Thermophys Eng 15(3):165–178

Lekholm V, Palmer K, Ericson F, Thornell G (2011) Ceramic cold gas microthruster with integrated flow sensor. PowerMEMS 2011:167–170

Liu MH (2005) Numerical study on micronozzles. J Eng Thermophys

Ljubchenko FN, Fedenev AV, Chumakov AN, Bosak NA, Tarasenko VF, Panchenko AN (2008) Novel concept of laser-plasma microthruster design Proceedings of SPIE—The International Society for. Opt Eng 7005:700520

Louisos WF, Hitt DL (2008) Viscous effects on performance of two-dimensional supersonic linear micronozzles. J Spacecr Rockets 45:706–715

Louisos W, Hitt DL (2012) Influence of wall heat transfer on supersonic micronozzle performance. J Spacecr Rockets 49:450–460

Louisos WF, Alexeenko AA, Hitt DL, Zilic A (2008) Design considerations for supersonic micronozzles. Int J Manuf Res 3(1):80–113

Miyakawa N, Legner W, Ziemann T, Telitschkin D, Fecht H-J, Friedberger A (2012) MEMS-based microthruster with integrated platinum thin film resistance temperature detector (RTD), heater meander and thermal insulation for operation up to 1,000 °C. Microsyst Technol 18:1077–1087. doi:10.1007/s00542-012-1441-0

Mueller J, Hofer R, Ziemer J (2010) Survey of propulsion technologies applicable to cubesats

Nathan GS, Stephen G, Xinfeng G (2013) A CFD Analysis of compressible flow through convergent-conical nozzles. 49th AIAA/ASME/SAE/ASEE joint propulsion conference. doi:10.2514/6.2013-3734

Piergentili F et al (2013) MEMS cold gas microthruster on Ursa Maior CubeSat. International Astronautical Federation

Pranajaya F, Cappelli M (2001) Development of a colloid micro-thruster for flight demonstration on the Emerald nanosatellite. 37th Joint propulsion conference and exhibit. doi:10.2514/6.2001-3330

Raitses Y, Fisch N, Ertmer K, Burlingame C (2000) A study of cylindrical hall thruster for low power space applications. 36th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibit. doi:10.2514/6.2000-3421

Ru C et al (2016) Superior performance of a MEMS-based solid propellant microthruster (SPM) array with nanothermites. Microsyst Technol. doi:10.1007/s00542-016-3159-x

Saad MA (1985) Compressible fluid flow. Prentice-Hall, New York

Shen Q, Yuan WZ, Li XP, Hao YC (2013) A fully decoupled design method for MEMS microthruster based on orthogonal analysis. Transducers & eurosensors Xxvii: the international conference on solid-state sensors, actuators and microsystems, pp 2353–2356

Shen Q, Yuan W, Li X, Xie J, Chang H (2014) An orthogonal analysis method for decoupling the nozzle geometrical parameters of microthrusters. Microsyst Technol 21:1157–1166. doi:10.1007/s00542-014-2240-6

Shen Q, Yuan W, Xie J, Chang H (2015) A quantitative optimisation model for a horizontal MEMS solid propellant thruster with experimental verification. Microsyst Technol 22:847–859. doi:10.1007/s00542-015-2486-7

Xiong J, Zhou Z, Ye X, Wang X, Feng Y, Li Y (2002) A colloid micro-thruster system. Microelectron Eng 61–62:1031–1037

Zhang KL, Chou SK, Ang SS (2004) Development of a solid propellant microthruster with chamber and nozzle etched on a wafer surface. J Micromech Microeng 14:785–792. doi:10.1088/0960-1317/14/6/004

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, X., Li, X., Zhou, J. et al. Numerical and experimental analysis of cold gas microthruster geometric parameters by univariate and orthogonal method. Microsyst Technol 23, 5003–5016 (2017). https://doi.org/10.1007/s00542-017-3451-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3451-4