Abstract

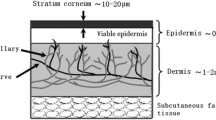

Due to the incapacity of many drugs to enter the skin at therapeutically useful rates, transdermal drug delivery with the advantages of controlled release, high safety and low degree of side effects is seriously hampered in efficiency and success. A microneedle approach can dramatically promote transdermal delivery, especially for macromolecules. In this paper, a fabrication process for hollow out-of-plane hafnium oxide microneedles on silicon wafer using only one mask has been developed. Photoresist is spun on a 4″ silicon (100) wafer and patterned by a mask. Deep reactive ion etching is used to form deep molds inside the wafer. A hafnium oxide film is deposited by atomic layer deposition to cover the top side of the wafer and the inside walls of the molds. Then the back side of silicon wafer is etched under the condition of 30 wt% KOH solution and a water-bath temperature of 81 °C until exposed hollow hafnium oxide microneedles are obtained. Compared to the processes that have been developed for silicon, silicon oxide, or polymer microneedles, the process presented here is simpler, and the strength and flexibility of hollow hafnium oxide microneedles can be easily adjusted by modifying the depositing time of hafnium oxide films. Hafnium oxide microneedles have potential applications in transdermal drug delivery.

Similar content being viewed by others

References

Aoyagi S, Izumi H, Isono Y, Fukuda M, Ogawa H (2007) Laser fabrication of high aspect ratio thin holes on biodegradable polymer and its application to a microneedle. Sens Actuators A 139(1–2):293–302

Bai Q, Wise KD (2001) Single-unit neural recording with active microelectrode arrays. IEEE Trans Biomed Eng 48(8):911–920

Elias PM, Feingold KP (2001) Coordinate regulation of epidermal differentiation and barrier homeostasis. Skin Pharmacol Appl Skin Physiol 14(Suppl. 1):28–34

French PJ, Gennissen TPJ, Sarro PM (1997) New silicon micromachining techniques for microsystems. Sens Actuators A 62(1–3):652–662

Frick TB, Marucci DD, Cartmill JA, Martin CJ, Walsh WR (2001) Risistance forces acting on suture needles. J Biomech 34(10):1335–1340

Gere JM, Timoshenko SP (1984) Mechanics of materials. CBS Publishers, New Delhi

Gill HG, Prausnitz MR (2007) Coated microneedles for transdrmal delivery. J Control Release 117(2):227–237

Giri Nandagopal MS, Antony R, Rangabhashiyam S, Sreekumar N, Selvaraju N (2014) Overview of microneedle system: a third generation transdermal drug delivery approach. Microsyst Technol 20(7):1249–1272

Hamilton JG (1995) Needle phobia: a neglected diagnosis. J Fam Pract 42(1):169–175

Henry S, McAllister DV, Allen MG, Prausniz MR (1998) Microfabricated microneedles: a new approach to transdermal drug deliver. J Pharm Sci 87(8):922–925

Huang H, Fu C (2007) Different fabrication methods of out-of-plane polymer hollow needle arrays and their variations. J Micromech Microeng 17(2):393–402

Jurcicek P, Zou H, Zhang S, Liu C (2013) Design and fabrication of hollow out-of-plane silicon microneedles. Micro Nano Lett 8(2):78–81

Kim K, Lee JB (2007) High aspect ratio tapered hollow metallic microneedle arrays with microfluidic interconnector. Microsist Technol 13(3–4):231–235

Lhernould MS (2013) Optimizing hollow microneedles arrays aimed at transdermal drug delivery. Microsist Technol 19(1):1–8

Matteucci M, Fanetti M, Casella M, Gramatica F, Gavioli L, Tormen M, Grenci G, Angelis FD, Di Fabrizio E (2009) Poly vinyl alcohol re-usable masters for microneedle replication. Microelectron Eng 86(4–6):752–756

Park J-H, Allen MG, Prausnitz MR (2006) Polymer microneedles for controlled-release drug delivery. Pharm Res 23(3):1008–1019

Parker ER, Rao MP, Turner KL, Meinhart CD, MacDonald NC (2007) Bulk micromachined titanium microneedles. J Microelectromech Syst 16(2):289–295

Prausnitz MR, Mitragotri S, Langer R (2004) Current status and future potential of transdermal drug deleivery. Nat Rev Drug Discov 3(2):115–124

Rajaraman S, Henderson HT (2005) A unique fabrication approach for microneedles using coherent porous silicon tchnology. Sens Actuators B 105(2):443–448

Stoeber B, Liepmann D (2005) Arrays of hollow out-of-plane microneedles for drug delivery. J Microelectromech Syst 14(3):472–479

Tanaka H, Yamashita S, Abe Y, Shikida M, Sato K (2004) Fast etching of silicon with a smooth surface in high temperature ranges near the boiling point of KOH solution. Sens Actuators A 114(2–3):516–520

Vinayakumar KB, Rajanna K, Dinesh NS (2016) Out-of-plane cup shaped stainless steel microneedle array for drug delivery. IEEE Annu Int Conf Nano/Micro Eng Mol Syst, NEMS 2016, Sendai, Japan, pp 172–175

Wang Y, Ho M-T, Goncharova LV, Weilunski LS, Rivillon-Amy S, Chabal YJ, Gustafsson T (2007) Characterizaion of ultra-thin hafnium oxide films grown on silicon by atomic layer deposition using tetrakis(ethylmethyl-amino) hafnium and water precursors. Chem Mater 19(13):3127–3138

Zhu J, Shen Q, Cao Y, Chen X, Zhao X (2016) The fabrication and property of a novel coated out-of-plane microneedle arrays. Microsyst Technol 22(1):143–149

Zubel I, Kramkowska M (2002) The effect of alcohol additives on etching characteristics in KOH solutions. Sens Actuators A 101(3):255–261

Acknowledgements

The authors would like to thank Tony Whipple, Mark Fisher, Paul Kimani and other members of the Minnesota Nano Center at the University of Minnesota for their advice and help. Funding was provided by State Scholarship Fund of China and the open research fund of Shanghai key Laboratory of Miltidimensional Information Processing, East China Normal University (Grant Nos. 201306145016 and 40500-542500-15202/007/002)

Author information

Authors and Affiliations

Corresponding author

Additional information

This work is supported by the State Scholarship Fund of China, and the open research fund of Shanghai Key Laboratory of Multidimensional Information Processing, East China Normal University, China.

Rights and permissions

About this article

Cite this article

Zhang, Yh., Campbell, S.A. & Karthikeyan, S. Preparation of hollow out-of-plane hafnium oxide microneedle arrays for transdermal drug delivery. Microsyst Technol 23, 5887–5892 (2017). https://doi.org/10.1007/s00542-017-3354-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3354-4