Abstract

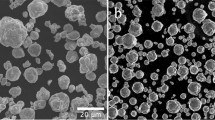

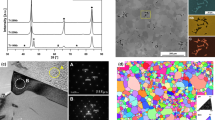

High strength nanocrystalline and amorphous Ni-14–24 at. % W alloys with their tensile strengths of about 3 GPa have been prepared by electrodeposition. Nano-microscale Ni–W alloy mould inserts, consisting of line and space structures with the line-widths of 700 and 300 nm and the height of 200 nm, were fabricated. High compression stress moulding of some metal plates of pure-Al, SUS-316L stainless steel and Zr69Cu16Ni5Al10 bulk metallic glass with the Ni–W alloy inserts was carried out at room temperature. In the case of the pure-Al under moulding stress of about 350 MPa, full moulding was achieved with the depths of about 200 nm approximately equal to the height of the inserts. Repeat moulding of 200 cycles did not cause any noticeable change or degradation of the Ni–W alloy inserts. In the case of the SUS-316L stainless steel under the moulding stress of about 1 GPa, however, the nano-microscale moulding was not achieved. This may be due to the high strain hardening ability of the SUS-316L stainless steel during plastic deformation. In the case of the Zr69Cu16Ni5Al10 bulk metallic glass with a high yielding stress of about 1.5 GPa and no strain hardening ability, full moulding was almost achieved successfully under the high moulding stress of about 2 GPa.

Similar content being viewed by others

References

Cao DM, Meng WJ (2004) Microscale compression molding of Al with surface engineered LIGA inserts. Microsyst Technol 10:662–670

Cao DM, Guidry D, Meng WJ, Kelly KW (2003) Molding of Pb and Zn with microscale mold inserts. Microsyst Technol 9:559–566

Ehrfeld W, Hessel V, Loewe H, Schltz CH, Webwer L (1997) Materials of LIGA technology In: Proceedings 2nd International Conference Micro Materials 97, Berlin, p 112

Fujita K, Suidu T, Yamasaki T (2010) High strength and high ductility in electrodeposited nanocrystalline Ni-W alloy. Mater Sci Forum 654–656:1118–1121

Fujita K, Suidu T, Yamasaki T (2011) Tensile properties in electrodeposited nanocrystalline Ni-W alloy. J Jpn Inst Metals 75(6):348–354

Hosokawa H, Yamasaki T, Sugamoto N, Tomizawa M, Shimojima K, Mabuchi M (2004) Bending properties of nanocrystalline Ni-18 at % W alloy produced by electrodeposition. Mater Trans 45:1807–1810

Igarashi K (2003) Mechanical properties of Al-based alloys (Tensile properties). Abstr Annu meet Archit Inst Jpn. pp 521–523

Jiang J, Fanghua M, Meng WJ, Lara-Curzio E (2008) Microscale molding replication of Cu and Ni-based structures. Microsyst Technol 14:1731–1737

Mekaru H (2013) Formation of metal nanostructures by high-temperature imprinting. Microsyst Technol. doi:10.1007/s00542-013-1789-9

Oda N, Matsuoka H, Yamasaki T, Fukami T (2005) High-strength nanocrystalline Ni-W electrodeposits and their precision forming at high temperature. J Metastable Nanocrystalline Mater 24–25:411–414

Yamada M, Yamasaki T, Yokoyama Y (2013) Tensile properties of Zr-based bulk metallic alloys. Unpublished data

Yamasaki T (2001) High-strength nanocrystalline Ni-W alloys produced by electrodeposition and their embrittlement behaviors during grain growth. Scripta Mater 44:1497–1502

Yamasaki T (2004) Formation of high strength nanocrystalline Ni-W electrodeposits and their ultrafine forming. Hyomen-Gijyutu Japanese J 55:242–247

Yamasaki T (2010) Book series on complex metallic alloys vol. 4, chapter 8. In: Ferre EB (ed) Mechanical properties of complex intermetallics. World Sci. Pub. Co Ltd, France, pp 273–316

Yamasaki T, Schlossmacher P, Ehrlich K, Ogino Y (1998) Formation of amorphous electrodeposited Ni-W alloys and their nanocrystallization. Nanostruct Mater 10:375–388

Yamasaki T, Tomohira R, Ogino Y, Schlossmacher P, Ehrlich K (2000) Formation of ductile amorphous and nanocrystalline Ni-W alloys by electrodeposition. Plat Surf Finish 87:148–152

Yoshida F (1997) Theory of engineering elasto-plasticity. Kyoritsu Shuppan Co. Ltd., Tokyo

Acknowledgments

This study was financially supported by the Grant-in-Aid for Scientific Research on Innovative Area, “Bulk Nanostructured Metals”, through MEXT, Japan [Contract No. 2201 (22102004)], and the support is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamasaki, T., Yamada, M., Adachi, H. et al. Nano-microscale moulding of some metal plates with high strength Ni–W alloy moulds. Microsyst Technol 20, 1941–1948 (2014). https://doi.org/10.1007/s00542-013-2005-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-2005-7