Abstract

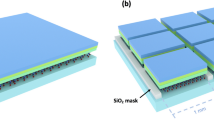

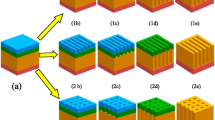

This paper presents a novel method to obtain structures with normative polygon cross section (PCS) shapes in a single crystal silicon substrate. A combination of wet etching and an after thermal oxidation (ATO) technique was used to fabricate several novel, complex structures with PCS shapes, which can hardly be fabricated by traditional wet etching. Based on such an innovative method, this paper proposes and develops three varieties of PCS silicon-beams. The subsequent experiment of fabricating silicon-beams with hexagonal sections has been taken as an example to validate the technique principle. Furthermore, the dimension parameters of the fabricated structures have been tested. Through this novel fabrication method, the sidewall arris of the fabricated silicon-beams can be maintained due to the protection of the ATO SiO2 layers, the arris disfigurement of the silicon-beam decreases dramatically and the quality of the silicon-beam is improved greatly.

Similar content being viewed by others

Abbreviations

- PCS:

-

Polygon cross section

- ATO:

-

After thermal oxidation

References

Alves MAR, Takeuti DF, Braga ES (2005) Fabrication of sharp silicon tips employing anisotropic wet etching and reactive ion etching. Microelectron J 36:51–54

Andersson GI, Hedenstierna N, Sevnsson P, Pettersson H (1999) A novel silicon bulk gyroscope. Transducer ’99. http://citeseerx.ist.psu.edu/viewdoc/summary? doi:10.1.1.199.8648

Archer MJ, Ligler FS (2008) Fabrication and characterization of silicon micro-funnels and tapered micro-channels for stochastic sensing applications. Sensors 8:3848–3872. doi:10.3390/s8063848

Brugger J, Beljakovic G, Despont M, Rooij NF, Vettiger P (1997) Silicon micro/nanomechanical device fabrication based on focused ion beam surface modification and KOH etching. Microelectron Eng 35:401–404

Canavese G, Marasso SL, Quaglio M, Cocuzza M, Ricciardi C, Pirri CF (2007) Polymeric mask protection for alternative KOH silicon wet etching. J Micromech Microeng 17:1387–1393. doi:10.1088/0960-1317/17/7/022

Chae J, Kulah K, Najafi K (2003) A monolithic three-axis silicon capacitive accelerometer with micro-g resolution. Transducer ’03. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=1215258

Hsu TR (2002) MEMS and Microsystem: design and manufacture. McGraw-Hill Science, Boston

Kovacs GTA, Maluf NI, Petersen KE (1998) Bulk micromachining of silicon. Proc IEEE 86:1536–1551

Mirabella DA, Suárez MP, Aldao CM (2009) Hillock sizes after wet etching in silicon. Surf Sci 603:3346–3349

Rödjegård H, Andersson GI, Rusu C, Löfgren M, Billger D (2005) Capacitive slanted-beam three-axis accelerometer: I. Model Des 15:1989–1995. doi:10.1088/0960-1317/15/11/001

Rouhi J, Mahmud S, Hutagalung SD, Naderi N, Kakooei S, Abdullah MJ (2012) Controlling the shape and gap width of silicon electrodes using local anodic oxidation and anisotropic TMAH wet etching. Semicond Sci Technol 27:1–11. doi:10.1088/0268-1242/27/6/065001

Sarajlic E, Yamahata C, Fujita H (2007) Towards wet anisotropic silicon etching of perfect pyramidal pits. Microelectron Eng 84:1419–1422

Schmidt B, Bischoff L, Teichert J (1997) Writing FIB implantation and subsequent anisotropic wet chemical etching for fabrication of 3D structure in silicon. Sens Actuat A 61:369–373

Walczak R, Dziuban J (2006) Fast wet anisotropic etching of silicon utilizing microwave treatment of KOH etchant. Meas Sci Technol 17:38–44. doi:10.1088/0957-0233/17/1/008

XinXin L, Takahito O, Yuelin W, Masayoshi E (2002) Study on ultra-thin NEMS cantilevers-high yield fabrication and size effect on young’s modulus of silicon. IEEE MEMS ’2002. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=984294&tag=1

Xiong W, Dingbang X, Zelong Z, Zhihua C, Xuezhong W, Shengyi L (2011) Support loss for beam undergoing coupled vibration of bending and torsion in rocking mass resonator. Sens Actuat A 171:199–206

Zhanqiang H, Dingbang X, Xuezhong W, Peitao D, Zhihua C, Zhengyi N, Xu Z (2011) Effect of axial force on the performance of micromachined vibratory rate gyroscopes Sensors. Sensors 11:296–309. doi:10.3390/s110100296

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC, Grant No. 51175506 and 51005239), and carried out at the Microsystem Laboratory, College of Mechanical Engineering and Automation, National University of Defense Technology. Especially, the authors are grateful to Xu Zhang, Xiaoshuang Guo and Tongzhi Zhou for their help in device fabrication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, D., Wang, X., Zhou, Z. et al. A novel fabrication method based on an after thermal oxidation process for the realization of silicon-beams with normative polygon cross sections shapes. Microsyst Technol 19, 1081–1086 (2013). https://doi.org/10.1007/s00542-012-1704-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1704-9