Abstract

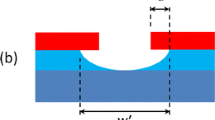

A cost effective method to fabricate nanopores in silicon by only using the conventional wet-etching technique is developed in this research. The main concept of the proposed method is a two-step etching process, including a premier double-sided wet etching and a succeeding track-etching. A special fixture is designed to hold the pre-etched silicon wafer inside it such that the track-etching can be effectively carried out. An electrochemical system is employed to detect and record the ion diffusion current once the pre-etched cavities are etched into a through nanopore. Experimental results indicate that the proposed method can cost effectively fabricate nanopores in silicon. A through pore with pore size being around 14 nm can be fabricated.

Similar content being viewed by others

References

Bezrukov SM, Vodyanoy I, Parsegian VA (1994) Counting polymers moving through a single ion channel. Nature 390:279–291

Fleischer RL, Rrice PB, Walker RM (1975) Nuclear tracks in solids: principles and applications. University of California Press, Berkeley

Howorka S, Cheley S, Bayley H (2001) Sequence-specific detection of individual DNA strands using engineered nanopores. Nat Biotechnol 19:636–639

Kim GM, Kovalgin A, Holleman J, Brugger J (2002) Replication molds having nanometer-scale shape control fabricated by means of oxidation and etching. J Nanosci Nanotechnol 2(1):55–59

Li J, Stein D, McMullan C, Branton D, Aziz MJ, Golovchenko JA (2001) Ion-beam sculpting at nanometre length scales. Nature 412(6843):166–169

Li J, Gershow M, Stein D, Brandin E, Golovchenko JA (2003) DNA molecules and configurations in a solid-state nanopore microscope. Nat Mater 2(9):611–615

Mliki N, Kaabi H, Bessais B, Yangui B, Saikaly W, Dominici C, Charai A (2003) Morphology and microstructure at different scales of porous silicon prepared by a nonconventional technique. J Nanosci Nanotechnol 3(5):413–419

Sauer-Budge AF, Nyamwanda JA, Lubensky DK, Branton D (2003) Unzipping kinetics of double-stranded DNA in a nanopore. Phys Rev Lett 90(23):238101–1(4)

Siwy Z, Fulinski A (2002) Fabrication of a synthetic nanopore ion pump. Phys Rev Lett 88(19):198103–1(4)

Siwy Z, Fulinski A (2004) A nanodevice for rectification and pumping ions. Am J Phys 72(5):567–574

Storm AJ, Chen JH, Ling XS, Zandbergen HW, Dekker C (2003) Fabrication of solid-state nanopores with single-nanometre precision. Nat Mater 2(8):537–540

Zhang H, Chen Z, Li T, Saito K (2005) Fabrication of a one-dimensional array of nanopores horizontally aligned on a Si substrate. J Nanosci Nanotechnol 5(10):1745–1758

Acknowledgments

The authors would like to thank the National Science Council of Taiwan, for financially supporting this work under Contract No. NSC-96-2212-E-005-024. The Center of Nanoscience and Nanotechnology at National Chung-Hsing University, Taiwan, is appreciated for use of its facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, GJ., Chen, WZ. & Chang, K.J. A two-step etching method to fabricate nanopores in silicon. Microsyst Technol 14, 925–929 (2008). https://doi.org/10.1007/s00542-007-0481-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-007-0481-3