Abstract

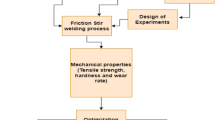

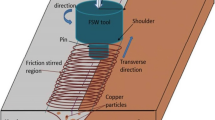

The friction stir welding (FSW) process is a prominent approach to fabricate high-quality welds for materials having low melting temperatures. Welding quality criteria have been extensively considered in former publications. The purpose of the current work is to optimize process parameters, including the tool rotational speed (N), travel speed (V), plunging depth (P), and tilting angle (A) for decreasing the energy consumption in the welding time (EW) and improving the ultimate tensile strength (UTS) as well as and percent elongation (PEL) for the FSW operation of dissimilar aluminum alloys. The adaptive neuro-based fuzzy inference system (ANFIS) approach is utilized to develop the FSW responses in terms of optimizing inputs, while a novel model is developed to compute the production cost (PC). The grey relational analysis (GRA) is applied to calculate the weight of each response. The vibration and communication particle swarm optimization (VCPSO) algorithm and combined compromise solution (CCS) are applied to produce feasible solutions and determine the best optimal point. The obtained outcomes presented that the optimum outcomes of the N, V, P, and A are 1500 RPM, 56 mm/min, 0.98 mm, and 2 deg., respectively, while the EW, UTS, and PEL are enhanced by 13.3%, 7.4%, and 55.7% at the optimal solution. The optimal ANFIS models were trustworthy and ensure accurate predictions. The developed method using the ANFIS, VCPSO, and CCS could be effectively utilized to determine the optimal outcomes instead of the trial–error and/or human experience. The observed findings provided efficient information, which could help operators to select the optimal FSW parameters and enhance the welding responses.

Similar content being viewed by others

References

Kasman Ş (2013) Multi-response optimization using the Taguchi-based grey relational analysis: a case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111. Int J Adv Manuf Technol 68:795–804. https://doi.org/10.1007/s00170-012-4720-0

Babajanzade RS, Behboodi JM, Teimouri R, Asgharzadeh-Ahmadi G, Falahati-Naghibi M, Sohrabpoor H (2013) Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol 69:1803–1818. https://doi.org/10.1007/s00170-013-5131-6

Karthikeyan R, Balasubramanian V (2013) Statistical optimization and sensitivity analysis of friction stir spot welding process parameters for joining AA 7075 aluminum alloy. Exp Tech 37:6–15. https://doi.org/10.1111/j.1747-1567.2011.00746.x

Chase DC, Brian TG, David RD, Alvin MS, George EC (2014) A method for double-sided friction stir spot welding. J Manuf Process 16:241–247. https://doi.org/10.1016/j.jmapro.2013.10.006

Cook GE, Crawford R, Clark DE, Strauss AM (2004) Robotic friction stir welding. Ind Robot 31:55–63. https://doi.org/10.1108/01439910410512000

Ahmadi H, Mostafa ANB, Ghasemi FA (2014) Optimization of process parameters for friction stir lap welding of carbon fibre reinforced thermoplastic composites by Taguchi method. J Mech Sci Technol 28:279–284. https://doi.org/10.1007/s12206-013-0966-1

Shojaeefard MH, Akbari M, Asadi P (2014) Multi objective optimization of friction stir welding parameters using FEM and neural network. Int J Precis Eng Manuf 15:2351–2356. https://doi.org/10.1007/s12541-014-0600-x

Senthilraja R, Sait AN (2015) Optimization of the parameters of friction stir welding for AZ91D magnesium alloy using the Taguchi design. Mater Sci 51:180–187. https://doi.org/10.1007/s11003-015-9826-8

Kumar S, Kumar S (2015) Multi-response optimization of process parameters for friction stir welding of joining dissimilar Al alloys by gray relation analysis and Taguchi method. J Braz Soc Mech Sci Eng 37:665–674. https://doi.org/10.1007/s40430-014-0195-2

Saeidi M, Manafi B, Besharati Givi M, Faraji G (2016) Mathematical modeling and optimization of friction stir welding process parameters in AA5083 and AA7075 aluminum alloy joints. Proc Inst Mech Eng B 230(7):1284–1294. https://doi.org/10.1177/0954405415573697

Longhurst WR, Cox CD, Gibson BT, George EC, Alvin MS, Isaac CW, Brandon EO (2017) Development of friction stir welding technologies for in-space manufacturing. Int J Adv Manuf Technol 90:81–91. https://doi.org/10.1007/s00170-016-9362-1

Salari E, Jahazi M, Khodabandeh A, Nanesa HG (2016) Friction stir lap welding of 5456 aluminum alloy with different sheet thickness: process optimization and microstructure evolution. Int J Adv Manuf Technol 82:39–48. https://doi.org/10.1007/s00170-015-7342-5

Siddharth S, Senthilkumar T (2016) Optimization of friction stir spot welding process parameters of dissimilar Al 5083 and C 10100 joints using response surface methodology. Russ J Non-ferrous Metals 57:456–466. https://doi.org/10.3103/S1067821216050151

Trueba L, Torres MA, Johannes LB, Rybicki D (2018) Process optimization in the self-reacting friction stir welding of aluminum 6061–T6. Int J Mater Form 11:559–570. https://doi.org/10.1007/s12289-017-1365-4

Farzadi A, Bahmani M, Haghshenas DF (2017) Optimization of operational parameters in friction stir welding of AA7075-T6 aluminum alloy using response surface method. Arab J Sci Eng 42:4905–4916. https://doi.org/10.1007/s13369-017-2741-6

William TE, Cox CD, Gibson BT, Alvin MS, George EC (2016) Two-sided friction stir riveting by extrusion: a process for joining dissimilar materials. J Manuf Process 23:115–121. https://doi.org/10.1016/j.jmapro.2016.06.001

Colmenero AN, Orozco MS, Macías EJ, Fernandez JB, Muro JCSD, Fals HC, Roca AS (2019) Optimization of friction stir spot welding process parameters for Al-Cu dissimilar joints using the energy of the vibration signals. Int J Adv Manuf Technol 100:2795–2802. https://doi.org/10.1007/s00170-018-2779-y

Palanivel R, Laubscher R, Vigneshwaran S, Dinaharan I (2018) Prediction and optimization of the mechanical properties of dissimilar friction stir welding of aluminum alloys using design of experiments. Proc Inst Mech Eng B 232(8):1384–1394. https://doi.org/10.1177/0954405416667404

D’Orazio A, Forcellese A, Simoncini M (2019) Prediction of the vertical force during FSW of AZ31 magnesium alloy sheets using an artificial neural network-based model. Neural Comput Appl 31:7211–7226. https://doi.org/10.1007/s00521-018-3562-6

Alkayem NF, Parida B, Pal S (2019) Optimization of friction stir welding process using NSGA-II and DEMO. Neural Comput Appl 31:947–956. https://doi.org/10.1007/s00521-017-3059-8

Ma Z, Li Q, Ma L, Hu W, Xu B (2019) Process parameters optimization of friction stir welding of 6005A–T6 aluminum alloy using Taguchi technique. Trans Indian Inst Met 72:1721–1731. https://doi.org/10.1007/s12666-019-01639-7

Kamal Babu K, Panneerselvam K, Sathiya P, Noorul Haq A, Sundarrajan S, Mastanaiah P, Srinivasa Murthy CV (2018) Parameter optimization of friction stir welding of cryorolled AA2219 alloy using artificial neural network modeling with genetic algorithm. Int J Adv Manuf Technol 94:3117–3129. https://doi.org/10.1007/s00170-017-0897-6

Senthil SM, Parameshwaran R, Ragu Nathan S, Bhuvanesh Kumar M, Deepandurai K (2020) A multi-objective optimization of the friction stir welding process using RSM-based-desirability function approach for joining aluminum alloy 6063–T6 pipes. Struct Multidisc Optim 62:117–1133. https://doi.org/10.1007/s00158-020-02542-2

Bhatia A, Wattal R (2021) Process parameters optimization for maximizing tensile strength in friction stir-welded carbon steel. Stroj Vestn J Mech Eng 67(6):311–321. https://doi.org/10.5545/sv-jme.2021.7203

Boukraa M, Chekifi T, Lebaal N (2022) Friction stir welding of Aluminum using a multi-objective optimization approach based on both Taguchi method and grey relational analysis. Exp Tech. https://doi.org/10.1007/s40799-022-00573-6

Vasantha Kumar K, Balasubramanian M (2022) Optimization of FSW processing factors on hardness for dissimilar AA6061-T6 and AZ31B O alloys. Stroj Vestn J Mech Eng 68(3):166–174. https://doi.org/10.5545/sv-jme.2021.7316

MohammadiSefat M, Ghazanfari H, Blais C (2021) Friction stir welding of 5052–H18 aluminum alloy: modeling and process parameter optimization. J of Materi Eng and Perform 30:1838–1850. https://doi.org/10.1007/s11665-021-05499-5

Jia H, Wu K, Sun Y, Hu F, Lin Y, Zhang H (2021) Experimental research and process parameter optimization of high-speed friction stir welding. Int J Adv Manuf Technol 115:3829–3838. https://doi.org/10.1007/s00170-021-07369-9

Jambhale S, Kumar S, Kumar S (2021) Characterization and optimization of flat friction stir spot welding of triple sheet dissimilar aluminium alloy joints. SILICON. https://doi.org/10.1007/s12633-020-00876-6

Sharma N, Khan ZA, Siddiquee AN, Wahid MA (2019) Multi-response optimization of friction stir welding process parameters for dissimilar joining of Al6101 to pure copper using standard deviation based TOPSIS method. Proc Inst Mech Eng C 233(18):6473–6482. https://doi.org/10.1177/0954406219858628

Gupta SK, Pandey K, Kumar R (2018) Artificial intelligence-based modelling and multi-objective optimization of friction stir welding of dissimilar AA5083-O and AA6063-T6 aluminium alloys. Proc Inst Mech Eng L 232(4):333–342. https://doi.org/10.1177/1464420715627293

Verma S, Kumar V (2021) Optimization of friction stir welding parameters of dissimilar aluminium alloys 6061 and 5083 by using response surface methodology. Proc Inst Mech Eng C. https://doi.org/10.1177/09544062211005804

Banik A, Saha A, Deb Barma J, Acharya U, Chandra Saha S (2020) Determination of best tool geometry for friction stir welding of AA 6061–T6 using hybrid PCA-TOPSIS optimization method. Measurement. https://doi.org/10.1016/j.measurement.2020.10

Shinde GV, Arakerimath RR (2021) Multi-response optimization of friction stir welding process of dissimilar AA3003-H12 and C12200–H01 alloys using full factorial method. Proc Inst Mech Eng E 235(5):1555–1564. https://doi.org/10.1177/09544089211008280

Kristjanpoller W, Astudillo N, Olson JE (2022) An empirical application of a hybrid ANFIS model to predict household over-indebtedness. Neural Comput Appl. https://doi.org/10.1007/s00521-022-07389-w

Machesa MGK, Tartibu LK, Okwu MO (2022) Performance analysis of stirling engine using computational intelligence techniques (ANN & Fuzzy Mamdani Model) and hybrid algorithms (ANN-PSO & ANFIS). Neural Comput Appl. https://doi.org/10.1007/s00521-022-07385-0

Jahed Armaghani D, Harandizadeh H, Momeni E (2021) Load carrying capacity assessment of thin-walled foundations: an ANFIS–PNN model optimized by genetic algorithm. Eng Comput. https://doi.org/10.1007/s00366-021-01380-0

Arthur CK, Temeng VA, Ziggah YY (2020) Novel approach to predicting blast-induced ground vibration using Gaussian process regression. Eng Comput 36:29–42. https://doi.org/10.1007/s00366-018-0686-3

Abifarin JK (2021) Taguchi grey relational analysis on the mechanical properties of natural hydroxyapatite: effect of sintering parameters. Int J Adv Manuf Technol 117:49–57. https://doi.org/10.1007/s00170-021-07288-9

Tang B, Xiang K, Pang M (2020) An integrated particle swarm optimization approach hybridizing a new self-adaptive particle swarm optimization with a modified differential evolution. Neural Comput Appl 32:4849–4883. https://doi.org/10.1007/s00521-018-3878-2

Flori A, Oulhadj H, Siarry P (2022) QUAntum particle swarm optimization: an auto-adaptive PSO for local and global optimization. Comput Optim Appl 82:525–559. https://doi.org/10.1007/s10589-022-00362-2

Houda T, Beji L, Amouri A, Mallem M (2022) Handiski simulator performance under PSO-based washout and control parameters optimization. Nonlinear Dyn. https://doi.org/10.1007/s11071-022-07626-w

Gupta N, Saxena J, Bhatia KS (2020) Optimized metamaterial-loaded fractal antenna using modified hybrid BF-PSO algorithm. Neural Comput Appl 32:7153–7169. https://doi.org/10.1007/s00521-019-04202-z

Yazdani M, Zarate P, Kazimieras Zavadskas E, Turskis Z (2019) A combined compromise solution (CoCoSo) method for multi-criteria decision-making problems. Manag Decis 57(9):2501–2519. https://doi.org/10.1108/MD-05-2017-0458

Tavana M, Shaabani A, Di Caprio D, Bonyani A (2022) A novel Interval Type-2 Fuzzy best-worst method and combined compromise solution for evaluating eco-friendly packaging alternatives. Expert Syst Appl 200:117188. https://doi.org/10.1016/j.eswa.2022.117188

Kalaiselvi R, Kousalya K (2020) Statistical modelling and parametric optimization in document fragmentation. Neural Comput Appl 32:5909–5918. https://doi.org/10.1007/s00521-019-04068-1

Williamson K, Cho H, Sousedík B (2021) Application of adaptive ANOVA and reduced basis methods to the stochastic Stokes-Brinkman problem. Comput Geosci 25:1191–1213. https://doi.org/10.1007/s10596-021-10048-z

Guo Y, Duflou JR, Lauwers B (2014) Energy-based optimization of the material stock allowance for turning-grinding process sequence. Int J Adv Manuf Technol 75:503–513. https://doi.org/10.1007/s00170-014-6139-2

Camposeco-Negrete C, de Dios C-NJ (2019) Optimization of energy consumption and surface roughness in slot milling of AISI 6061 T6 using the response surface method. Int J Adv Manuf Technol 103:4063–4069. https://doi.org/10.1007/s00170-019-03848-2

Li W, Kara S (2011) An empirical model for predicting energy consumption of manufacturing processes: a case of turning process. Proc Inst Mech Eng B 225(9):1636–1646. https://doi.org/10.1177/2041297511398541

Pimenov DY, Abbas AT, Gupta MK, Erdakov IN, Soliman MS, Rayes MM (2020) Investigations of surface quality and energy consumption associated with costs and material removal rate during face milling of AISI 1045 steel. Int J Adv Manuf Technol 107:3511–3525. https://doi.org/10.1007/s00170-020-05236-7

Nguyen TT, Nguyen TA, Trinh QH, Le XB (2022) Multi-performance optimization of multi-roller burnishing process in sustainable lubrication condition. Mater Manuf Process 37(4):407–427. https://doi.org/10.1080/10426914.2021.1962533

Nguyen T, Le T (2021) Optimization of the internal roller burnishing process for energy reduction and surface properties. Stroj Vestn J Mech Eng 67(4):167–179. https://doi.org/10.5545/sv-jme.2021.7106

Elyasi M, Aghajani Derazkola H, Hosseinzadeh M (2016) Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc Inst Mech Eng B 230(7):1234–1241. https://doi.org/10.1177/0954405416645986

Funding

This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 107.04–2020.02.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen, TT., Nguyen, CT. & Van, AL. Sustainability-based optimization of dissimilar friction stir welding parameters in terms of energy saving, product quality, and cost-effectiveness. Neural Comput & Applic 35, 5221–5249 (2023). https://doi.org/10.1007/s00521-022-07898-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-022-07898-8