Abstract

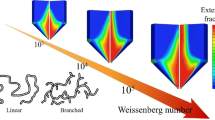

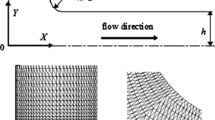

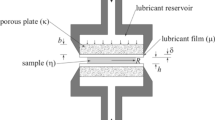

The excess pressure losses due to end effects (mainly entrance) in the capillary flow of a branched polypropylene melt were studied both experimentally and theoretically. These losses were first determined experimentally as a function of the contraction angle ranging from 10° to 150°. It was found that the excess pressure loss function decreases for the same apparent shear rate with increasing contraction angle from 10° to about 45°, and consequently slightly increases from 45° up to contraction angles of 150°. Numerical simulations using a multimode K-BKZ viscoelastic and a purely viscous (Cross) model were used to predict the end pressures. It was found that the numerical predictions do agree well with the experimental results for small contraction angles up to 30°. However, the numerical simulations under-predict the end pressure for larger contraction angles. The effects of viscoelasticity, shear, and elongation on the numerical predictions are also assessed in detail. Shear is the dominant factor controlling the overall pressure drop in flows through small contraction angles. Elongation becomes important at higher contraction angles (greater than 45°). It is demonstrated in abrupt contractions (angle of 180°) that both the entrance pressure loss and the vortex size are strongly dependent on the extensional viscosity for this branched polymer. It is suggested that such an experiment (visualisation of entrance flow) can be useful in evaluating the validity of constitutive equations and it can also be used to fitting parameters of rheological models that control the elongational viscosity.

Similar content being viewed by others

References

Bagley EB (1957) End corrections in the capillary flow of polyethylene. J Appl Phys 28:193–209

Barakos G, Mitsoulis E (1995a) Numerical simulation of extrusion through orifice dies and prediction of Bagley correction for an IUPAC-LDPE melt. J Rheol 39:193–209

Barakos G, Mitsoulis E (1995b) A convergence study for the numerical simulation of the IUPAC-LDPE extrusion experiments. J Non-Newtonian Fluid Mech 58:315–329

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology. Elsevier, Amsterdam

Beraudo C, Coupez T, Fortin A, Demay Y, Vergnes B, Agassant JF (1996) Viscoelastic computations in 2-D flow geometries: comparison with experiments on molten polymers. In: Ait-Kadi A, Dealy JM, James DF, Williams MC (eds) Proceedings of the XIIth International Congress on Rheology, Quebec City, pp. 417–418

Binding DM (1988) An approximate analysis for contraction and converging flows. J Non-Newtonian Fluid Mech 27:173–189

Binding DM (1991) Further considerations of axisymmetric contraction flows. J Non-Newtonian Fluid Mech 41:27–42

Boger DV (1987) Viscoelastic flows through contractions. Annu Rev Fluid Mech 19:157–182

Cogswell FN (1972) Measuring the extensional rheology of polymer melts. Trans Soc Rheol 16:383–403

Cogswell FN (1981) Polymer melt rheology—a guide to industrial practice. Wiley

Dealy JM, Wissbrun KF (1990) Melt rheology and its role in plastics processing—theory and applications. Van Nostrand Reinhold, New York

Feigl K, Öttinger HC (1994) The flow of a LDPE melt through an axisymmetric contraction: a numerical study and comparison to experimental results. J Rheol 38:847–874

Gotsis AD (2002) Private communication to the authors, Univ. of Delft, the Netherlands

Gotsis AD, Odriozola A (1998) The relevance of entry flow measurements for the estimation of extensional viscosity of polymer melts. Rheol Acta 37:430–437

Guillet J, Revenue P, Bereaux Y, Clermont J-R (1996) Experimental and numerical study of entry flow of low-density polyethylene melts. Rheol Acta 35:494–507

Hatzikiriakos SG (2000) Long chain branching and polydispersity effects on the rheological properties of polyethylenes. Polym Eng Sci 40:2279–2287

Hatzikiriakos SG, Dealy JM (1992) Wall slip of molten high density polyethylene. II. Capillary rheometer studies. J Rheol 36:703–741

Hatzikiriakos SG, Mitsoulis E (1996) Excess pressure losses in the capillary flow of molten polymers. Rheol Acta 35:545–555

Kajiwara T, Barakos G, Mitsoulis E (1995) Rheological characterization of polymer solutions and melts with an integral constitutive equation. Int J Polym Anal Charact 1:201–215

Kazatchkov IB, Yip F, Hatzikiriakos SG (2000) The effect of boron nitride on the rheology and processing of polyolefins. Rheol Acta 39:583–594

Laun HM (1983) Polymer melt rheology with a slit die. Rheol Acta 22:171–185

Laun HM (1986) Prediction of elastic strains of polymer melts in shear and elongation. J Rheol 30:459–501

Laun HM, Schuch H (1989) Transient elongational viscosities and drawability of polymer melts. J Rheol 33:119–175

Luo X-L, Mitsoulis E (1990) An efficient algorithm for strain history tracking in finite element computations of non-Newtonian fluids with integral constitutive equations. Int J Num Meth Fluids 11:1015–1031

Luo X-L, Tanner RI (1988) Finite element simulation of long and short circular die extrusion experiments using integral models. Int J Num Meth Eng 25:9–22

Mitsoulis E, Vlachopoulos J, Mirza FA (1985) A numerical study of the effect of normal stresses and elongational viscosity on entry vortex growth and extrudate swell. Polym Eng Sci 25:677–689

Mitsoulis E, Hatzikiriakos SG, Christodoulou K, Vlassopoulos D (1998) Sensitivity analysis of the Bagley correction to shear and extensional rheology. Rheol Acta 37:438–448

Padmanabhan M, Macosco CW (1997) Extensional viscosity from entrance pressure drop measurements. Rheol Acta 36:144–151

Papanastasiou AC, Scriven LE, Macosco CW (1983) An integral constitutive equation for mixed flows: viscoelastic characterization. J Rheol 27:387–410

Rajagopalan D (2000) Computational analysis of techniques to determine extensional viscosity from entrance flows. Rheol Acta 39:138–151

Rothstein JP, McKinley GH (1999) Extensional flow of a polystyrene Boger fluid through a 4:1:4 axisymmetric contraction/expansion. J Non-Newtonian Fluid Mech 86:61–88

Acknowledgements

Financial assistance from the Natural Sciences and Engineering Research Council (NSERC) of Canada and the General Secretariat for Research and Technology (GGET) of Greece are gratefully acknowledged. The authors are indebted to Prof. Alexander Gotsis of the University of Delft for providing rheological experimental data, especially on the elongational viscosity.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mitsoulis, E., Hatzikiriakos, S.G. Bagley correction: the effect of contraction angle and its prediction. Rheol Acta 42, 309–320 (2003). https://doi.org/10.1007/s00397-003-0294-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-003-0294-y