Abstract

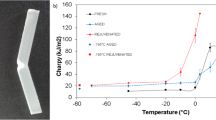

The microindentation hardness,H, of uniaxially deformed isotactic polypropylene samples was determined near the neck region, as a function of the draw ratio. The microhardness technique appears to be a valuable tool to describe mechanical properties in localized regions within a material and is capable of following changes in the semicrystalline structure during deformation. Differences in the microhardness behaviour of the two types of polymorphic forms, α and β, of isotactic polypropylene are discussed in terms of the two specific types of morphology, i.e. the cross-hatched arrangement of the crystalline lamellae for the α form and the parallel lamellar stacking for the β form. The changes of H as a function of λ are shown to be in accordance with the transformation in the neck from the spherulitic into the fibre structure. The steep H-decrease observed in the neck region is discussed in the light of the nanomechanical processes as revealed by scanning electron microscopy. These include lamellar separation, micro-void formation and fibrillation. Finally, microindentation experiments carried out in the neck allow an estimation of the local draw ratio at which the maximum pore content in the polypropylene samples occurs.

Similar content being viewed by others

References

Moore EP (1996) Polypropylene handbook. Hanser Verlag, Munich

Karger-Kocsis J (ed) (1995) Polypropylene: structure, blends and composites, vol 1. Structure and morphology. Chapman and Hall, London

Karian HG (ed) (1999) Handbook of polypropylene and polypropylene composites. Marcel Dekker, New York

Michler GH (1992) Kunststoff-Mikromechanik: morphologie, deformations—und Bruchmechanismen. Hanser, München

Peterlin A (1975) Colloid Polym Sci 253:809

Varga J (2002) J Macromol Sci Phys B 41(4–6):1121

Kausch HH, Plummer CJG (2001) Encyclopedia of materials: science and technology. Elsevier, Amsterdam

Baltá Calleja FJ, Peterlin A (1970) J Macromol Sci Phys B 4(3):519

Huang MR, Li XG, Fang BR (1995) J Appl Polym Sci 56:1323

Fujiyama M (1999) Intern Polym Processing 14:75

Turner Jones A, Aizlewood JM, Beckett DR (1964) Makromol Chem 75:134

Riekel C, Karger-Kocsis J (1999) Polymer 40:541

Karger-Kocsis J (1996) Polym Bull 36:119

Grein C, Plummer CJG, Kausch HH, Germain Y, Béguelin P (2002) Polymer 43:3279

Chen HB, Karger-Kocsis J, Wu JS, Varga J (2002) Polymer 43:6505

Tjong SC, Shen JS, Li RKY (1996) Polym Eng Sci 36:100

Dijkstra PTS, van Dijk DJ, Huétnik J (2002) Polym Eng Sci 42:152

Aboulfaraj M, G’Sell C, Ulrich B, Dahoun A (1995) Polymer 731–742

Li JX, Cheung WL, Chan CM (1999) Polymer 40:3641

Yoshida T, Fujiwara Y, Asano T (1983) Polymer 24:925

Chu F, Yamaoka T, Kimura Y (1994) Polymer 35:3442

Baltá Calleja FJ, Fakirov S (2000) Microhardness of polymers. Cambridge University Press, Cambridge

Baltá Calleja FJ In: Cunha AM, Fakirov S (eds) Structure development during polymer processing. Kluwer, Dordrecht pp 145–162

Michler GH, Ensslen M, Baltá-Calleja FJ, Könczöl L, Döll W (1999) Phil Mag A 79:167

García Gutiérrez MC, Michler GH, Henning S, Schade C (2001) J Macromol Sci Phys B 40:797

Baltá Calleja FJ, Giri L, Ezquerra TA, Fakirov S, Roslaniec Z (1997) J Macromol Sci Phys B 36:655

Baltá Calleja FJ (1976) Colloid Polym Sci 254:258

Flores A, Baltá Calleja FJ, Basset DC (1999) J Polym Sci Polym Phys 37:3151

Krumova M, Karger-Kocsis J, Baltá Calleja FJ, Fakirov S (1999) J Mater Sci 34:2371

Borealis data sheet P1078 07.06.2001 Ed. 1, http://www.borealisgroup.com/public/customer/data_sheets/Data_sheets.jsp

Borealis data sheet P0932 10.01.2002 Ed. 5, http://www.borealisgroup.com/public/customer/data_sheets/Data_sheets.jsp

Olley R, Bassett DC, Hine PJ, Ward IM (1993) J Mater Sci 28:1107

Baltá Calleja FJ, Martínez Salazar J, Asano T (1988) J Mater Sci Lett 7:165

Michler GH (1992) Colloid Polym Sci 270:627

Henning S, Adhikari R, Michler GH, Baltá Calleja FJ, Karger-Kocsis J (2004) Macromol Symp 214:157–171

Acknowledgements

We thank the Deutsche Forschungsgemeinschaft and the Kultusministerium des Landes Sachsen-Anhalt and MEC, Spain (grant FIS 2004-01331) for the support of this work. The financial support from the Deutscher Akademischer Austauschdient (DAAD) and from the Alexander von Humboldt-Stiftung is gratefully acknowledged. One of us (G.H.M.) thanks the Dirección General de Universidades, Ministerio de Educación, Spain, for the award of the Humboldt-Mutis Prize. S. Henning acknowledges a research scholarship from the Max-Buchner-Forschungsstiftung (MBFSt 2280) of the DECHEMA. Prof. J. Karger-Kocsis is thanked for the cooperation and supply of the materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Henning, S., Michler, G.H., Ania, F. et al. Microhardness of α- and β-modified isotactic polypropylene at the initial stages of plastic deformation: analysis of micromechanical processes. Colloid Polym Sci 283, 486–495 (2005). https://doi.org/10.1007/s00396-004-1199-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-004-1199-8