Abstract

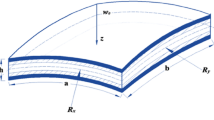

A geometrically nonlinear analysis of elastoplastic ceramic/metal functionally graded material (FGM) shells is investigated in this paper based on the first-order shear deformation theory. The elastoplastic behavior of the ceramic particle-reinforced metal matrix FGM shell is assumed to follow Ludwik hardening law. The elastoplastic material properties are assumed to vary smoothly through the thickness of the shells. The Mori–Tanaka model and self-consistent formulas of Suquet are employed to locally evaluate effective elastoplastic parameters of the ceramic/metal FGM composite. The homogenization formulation and numerical algorithms are implemented into ABAQUS/Standard via a user material subroutine (UMAT) developed to study the FG shells in large displacements and rotations. With the aim of demonstrating the accuracy of the present method, current numerical results are compared to experimental and numerical ones considering geometrically nonlinear elastoplastic FGMs and show very good agreement. The overall robustness of the new developed solution taking into account both geometric and material nonlinearities is demonstrated through several non-trivial benchmark problems taken from the literature. The effect of the constituent distribution on the deflections is analyzed.

Similar content being viewed by others

References

Pompea W, Worch H, Epple M, Friess W, Gelinsky M, Greil P, Hempele U, Scharnweber D, Schulte K (2003) Functionally graded materials for biomedical applications. Mater Sci Eng A 362(1–2):40–60

Alizadeh M, Fattahi AM (2018) Non-classical plate model for FGMs. Eng Comput. https://doi.org/10.1007/s00366-018-0594-6

Kidane A, Shukla A (2008) Dynamic constitutive behavior of Ti/TiB FGM under thermo mechanical loading. J Mater Sci 43:2771–2777

Yang J, Shena HS (2003) Non-linear analysis of functionally graded plates under transverse and in-plane loads. Int J Non-Linear Mech 38:467–482

Woo J, Merguid SA (2001) Non-linear analysis of functionally graded plates and shallow shells. Int J Solids Struct 38:7409–7421

Rajasekaran S (2018) Analysis of axially functionally graded nano-tapered Timoshenko beams by element-based Bernstein pseudospectral collocation (EBBPC). Eng Comput 34(3):543–563 (2018). https://doi.org/10.1007/s00366-017-0557-3

Ibrahim IA, Mohamed FA, Lavernia EJ (1991) Particulate reinforced metal matrix composites—a review. J Mater Sci 26(5):1137–1156

Tjong SC, Ma ZY (2000) Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng Rep 29(3–4):49–113

Praveen GN, Reddy JN (1998) Nonlinear transient thermoelastic analysis of functionally graded ceramic–metal plates. Int J Solids Struct 35:4457–4476

Trabelsi S, Frikha A, Zghal S, Dammak F (2018) Thermal post-buckling analysis of functionally graded material structures using a modified FSDT. Int J Mech Sci 144:74–89

Ma LS, Wang TJ (2003) Nonlinear bending and postbuckling of functionally graded circular plates under mechanical and thermal loadings”. Int J Non-Linear Mech 40:3311–3330

Kar VR, Panda S (2015) Large deformation bending analysis of functionally graded spherical shell using FEM. Struct Eng Mech 53(4):661–679

Katariya PV, Hirwani CK, Panda SK (2018) Geometrically nonlinear deflection and stress analysis of skew sandwich shell panel using higher-order theory. Eng Comput. https://doi.org/10.1007/s00366-018-0609-3

Kar VR, Panda SK (2016) Post-buckling behaviour of shear deformable functionally graded curved shell panel under edge compression. Int J Mech Sci 115:318–324

Kar VR, Panda SK (2015) Thermoelastic analysis of functionally graded doubly curved shell panels using nonlinear finite element method. Compos Struct 129:202–212

Mahapatra TR, Kar VR, Panda SK, Mehar K (2017) Nonlinear thermoelastic deflection of temperature-dependent FGM curved shallow shell under nonlinear thermal loading. J Therm Stress 40(9):1184–1199

Kar VR, Panda SK (2016) Nonlinear thermomechanical behavior of functionally graded material cylindrical/hyperbolic/elliptical shell panel with temperature-dependent and temperature-independent properties. J Press Vessel 138(6):061202

Panda SK, Katariya PV (2015) Stability and free vibration behaviour of laminated composite panels under thermo-mechanical loading. Int J App Comput Math 1(3):475–490

Kar VR, Panda SK (2015) Nonlinear flexural vibration of shear deformable functionally graded spherical shell panel. Steel Compos Struct 18(3):693–709

Kar VR, Panda SK (2016) Geometrical nonlinear free vibration analysis of FGM spherical panel under nonlinear thermal loading with TD and TID properties. J Therm Stress 39(8):942–959

Katariya PV, Panda SK, Mahapatra TR (2017) Prediction of nonlinear eigenfrequency of laminated curved sandwich structure using higher-order equivalent single-layer theory. J Sandw Struct Mater. https://doi.org/10.1177/1099636217728420

Zghal S, Frikha A, Dammak F (2018) Non-linear bending analysis of nanocomposites reinforced by graphene-nanotubes with finite shell element and membrane enhancement. Eng Struct 158:95–109

Zghal S, Frikha A, Dammak F (2018) Free vibration analysis of carbon nanotube-reinforced functionally graded composite shell structures. Appl Math Model 53:132–155

Zghal S, Frikha A, Dammak F (2017) Static analysis of functionally graded carbon nanotube-reinforced plate and shell structures. Compos Struct 176:1107–1123

Frikha A, Zghal S, Dammak F (2018) Dynamic analysis of functionally graded carbon nanotubes-reinforced plate and shell structures using a double directors finite shell element. Aerosp Sci Technol 78:438–451

Moita JS, Araújo AL, Mota Soares CM, Mota Soares CA, Herskovits J (2016) Material and geometric nonlinear analysis of functionally graded plate-shell Type structures. Appl Compos Mater 23:537–554

Tamura I, Tomota Y, Ozawa H (1973) Strength and ductility of Fe–Ni–C alloys composed of austenite and martensite with various strength. In: Proceedings of the third international conference on strength of metals and alloys, Cambridge: Institute of Metals, 1, pp. 611–5

Williamson RL, Rabin BH, Drake JT (1993) Finite element analysis of thermal residual stresses at graded ceramic/metal interfaces), part (I), pp. model description and geometrical effects. J Appl Phys 74:1310–1320

Vaghefi R, Hematiyan MR, Nayebi A (2016) Three-dimensional thermo-elastoplastic analysis of thick functionally graded plates using the meshless local Petrov–Galerkin method. Eng Anal Boundary Elem 71:34–49

Bocciarelli M, Bolzon G, Maier G (2008) A constitutive model of metal–ceramic functionally graded material behavior), pp. formulation and parameter identification. Comput Mater Sci 43:16–16

Orlik J (2010) Asymptotic homogenization algorithm for reinforced metal-matrix elastoplastic composites. Compos Struct 92(7):1581–1590

Suquet P (1997) Effective properties of nonlinear composites. In: Suquet P (ed) Continuum micromechanics. CISM Courses and Lecture Notes. Springer, Heidelberg, 377, pp. 197–264

Mars J, Chebbi E, Wali M, Dammak F (2018) Numerical and experimental investigations of low velocity impact on glass fiber-reinforced polyamide. Compos Part B 146(1):116–123

Mars J, Ben Said L, Wali M, Dammak F (2018) Elasto-plastic modelling of low-velocity impact on functionally graded circular plates. Int J Appl Mech 10(04):1850038

Bao G, Wang L (1995) Multiple cracking in functionally graded ceramic/metal coatings. Int J Solids Struct 32:2853–2871

Rahman S, Chakraborty A (2007) A stochastic micromechanical model for elastic properties of functionally graded materials. Mech Mater 39(6):548–563

Pettermann HE, Huber CO, Luxner MH, Nogales S, Böhm HJ (2010) An incremental Mori-tanaka homogenization scheme for finite strain thermoelastoplasticity of mmcs. Materials 3(1):434–451

Yu J, Kidane A (2014) Modeling functionally graded materials containing multiple heterogeneities. Acta Mech 225(7):1931–1943

Belhassen L, Koubaa S, Wali M, Dammak F (2016) Numerical prediction of springback and ductile damage in rubber-pad forming process of aluminum sheet metal. Int J Mech Sci 117:218–226

Wali M, Chouchene H, Ben Said L, Dammak F (2015) One-equation integration algorithm of a generalized quadratic yield functions with Chaboche non-linear isotropic/kinematic hardening. Int J Mech Sci 92:223–232

Wali M, Autay R, Mars J, Dammak F (2016) A simple integration algorithm for a non-associated anisotropic plasticity model for sheet metal forming. Int J Numer Meth Eng 107:183–204

Mars J, Wali M, Jarraya A, Dammak F, Dhiab A (2015) Finite element implementation of an orthotropic plasticity model for sheet metal in low velocity impact simulations. Thin-Walled Struct 89:93–100

Ben Said L, Mars J, Wali M, Dammak F (2017) Numerical prediction of the ductile damage in single point incremental forming process. Int J Mech Sci 131–132:546–558

Autay R, Koubaa S, Wali M, Dammak F (2018) Numerical implementation of coupled anisotropic plasticity-ductile damage in sheet metal forming process. J Mech 34(4):417–430. https://doi.org/10.1017/jmech.2017.28

Koubaa S, Mars J, Wali M, Dammak F (2017) Numerical study of anisotropic behavior of Aluminum alloy subjected to dynamic perforation. Int J Impact Eng 101:105–114

Gunes R, Aydin M, Apalak MK, Reddy JN (2014) Experimental and numerical investigations of low velocity impact on functionally graded circular plates. Compos Part B: Eng 59:21–32

Thai HT, Kim SE (2015) A review of theories for the modeling and analysis of functionally graded plates and shells. Compos Struct 128:70–86

(2014) Abaqus user's manual-version 6.14. Dassault Systems Simulia Corp, Providence, RI

Xu G, Huang H, Han Q (2018) Study on postbuckling of axial compressed elastoplastic functionally graded cylindrical shells. Mech Adv Mater Struct 25(10):820–828. https://doi.org/10.1080/15376494.2017.1308589

Kabir MZ, Nazari A (2011) The study of ultimate strength in notched cylinders subjected to axial compression. J Constr Steel Res 67(10):1442–1452

Teng JG, Hu YM (2007) Behaviour of FRP-jacketed circular steel tubes and cylindrical shells under axial compression. Constr Build Mater 21(4):827–838

Kim CH, Sze KY, Kim YH (2003) Curved quadratic triangular degenerated- and solid-shell elements for geometric nonlinear analysis. Int J Numer Meth Eng 57:2077–2097

Kim KD, Lomboy GR, HAN SC (2008) Geometrically non-linear analysis of functionally graded material (FGM) plates and shells using a four-node quasi-conforming shell element. J Compos Mater 42:485–511

Sze KY, Liua XH, Lob SH (2004) Popular benchmark problems for geometric nonlinear analysis of shells. Finite Elem Anal Des 40:1551–1569

Sze KY, Zheng SJ (2002) A stabilized hybrid-stress solid element for geometrically nonlinear homogeneous and laminated shell analyses. Comput Methods Appl Mech Eng 191:1945–1966

Sze KY, Chan WK, Pian THH (2002) An eight-node hybrid-stress solid-shell element for geometric nonlinear analysis of elastic shells”. Int J Numer Meth Eng 55:853–878

Sansour C, Kollmann FG (2000) Families of 4-nodes and 9-nodes finite elements for a finite deformation shell theory: an assessment of hybrid stress, hybrid strain and enhanced strain elements. Comput Mech 24(6):435–447

Simo JC, Fox DD, Rifai MS (1990) On a stress resultant geometrically exact shell model. Part (III), pp. computational aspects of the nonlinear theory. Comput Methods Appl Mech Eng 79:21–70

Simo JC, Rifai MS, Fox DD (1990) On a stress resultant geometrically exact shell model, part (IV), pp. variable thickness shells with through-the-thickness stretching. Comput Methods Appl Mech Eng 81: 91–96

Lee SJ, Kanok-Nukulchai W (1998) A nine-node assumed strain finite element for large deformation analysis of laminated shells. Int J Numer Meth Eng 42:777–798

Hong WI, Kim JH, Kim YH, Lee SW (2001) An assumed strain triangular curved solid shell element formulation for analysis for plates and shells undergoing finite rotations. Int J Numer Meth Eng 52:747–761

Arciniega RA, Reddy JN (2007) Large deformation analysis of functionally graded shells. Int J Solids Struct 44:2036–2052

Arciniega RA, Reddy JN (2007) Tensor-based finite element formulation for geometrically nonlinear analysis of shell structures. Comput Methods Appl Mech Eng 196:1048–1073

Rezaiee-Pajand M, Arabi E (2016) A curved triangular element for nonlinear analysis of laminated shells. Compos Struct 153:538–548

Balah M, Al-Ghamedy HN (2002) Finite element formulation of a third order laminated finite rotation shell element. Comput Struct 80:1975–1990

Mars J, Koubaa S, Wali M, Dammak F (2017) Numerical analysis of geometrically non-linear behavior of functionally graded shells. Latin Am J Solids Struct 14(11):1952–1978

Frikha A, Zghal S, Dammak F (2018) Finite rotation three and four nodes shell elements for functionally graded carbon nanotubes-reinforced thin composite shells analysis. Comput Methods Appl Mech Eng 329:289–311

Acknowledgements

The work is carried out thanks to the support and funding allocated to the Unit of Mechanical and Materials Production Engineering (UGPMM/UR17ES43) by the Tunisian Ministry of Higher Education and Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jrad, H., Mars, J., Wali, M. et al. Geometrically nonlinear analysis of elastoplastic behavior of functionally graded shells. Engineering with Computers 35, 833–847 (2019). https://doi.org/10.1007/s00366-018-0633-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-018-0633-3