Abstract

We report on the generation of a continuous-wave (CW) radially polarized beam with an Yb:Lu2O3 polycrystalline ceramic disk in a thin-disk laser (TDL) oscillator. A circular grating-waveguide mirror (CGWM) with a high polarization discrimination given by a reflectivity difference between the two orthogonal polarization states of 44.6% was used as a polarization-selective cavity end-mirror. An output power of 175 W was achieved with an optical efficiency of 39.6%. A high degree of radial polarization of 96.2% and a beam propagation factor of M2hor. = 2.05 and M2ver. = 2.32 were measured at the maximum output power.

Similar content being viewed by others

1 Introduction

Beams with radial and azimuthal polarization were previously reported to be useful for scientific applications such as particle trapping, imaging, plasmon excitation, tight focusing, superresolution imaging, data storage, information encryption, or photothermal therapy of cancer cells [1,2,3,4,5]. In addition, they were also found to be beneficial for industrial applications, in particular for material processing. It was experimentally demonstrated that the cutting velocity can be increased by 43% with a radially polarized beam at a wavelength of 1 µm as compared to an unpolarized beam [6]. The benefit of beams with azimuthal polarization for drilling and welding was reported in [7].

The TDL architecture has proven to be ideally suited to attain high-power laser output with radial polarization [8,9,10]. Output powers in the order of kW have already been reported with the established gain materials Yb:YAG and Yb:LuAG [11, 12]. As an alternative, the sesquioxide crystal Yb:Lu2O3 has attracted great attention because of its outstanding combination of spectral and thermal properties. The thermal conductivity of Yb:Lu2O3 amounts to 12 W/mK and therefore is almost twice as high as the one of Yb:YAG with a value of 7 W/mK for the same doping concentration of 8 × 1020 cm−3 [13]. In addition, the broader emission bandwidth of Yb:Lu2O3 (13 nm full-width at half maximum compared to 8.5 nm for Yb:YAG) [14] ensures the possibility to generate sub-100 fs pulses. These superior properties of Yb:Lu2O3 can be combined with the generation of axially symmetric polarization states such as radial or azimuthal polarizations as we report in this paper.

One of the most important reasons that limited the widespread use of Yb:Lu2O3 so far is the lack of high-quality large-area single crystals. The high melting temperature of \(\approx\) 2450 ºC complicates the fabrication process [15] and can lead to higher tension in the structure of the grown crystals. In fact, a single-crystal Yb:Lu2O3 has been reported to exhibit strong depolarization [16] that makes it more difficult to be used for the generation of radially and azimuthally polarized beams. The solution for the fabrication of Yb:Lu2O3 samples with larger volumes was found in the use of polycrystalline ceramics that has a reduced fabrication temperature of 1700 ºC [17]. Using a polycrystalline ceramic Yb:Lu2O3 disk operated in a TDL, a fundamental-mode output power of 409 W was demonstrated in 2021 with an optical efficiency of 35.6%, which marked a significant power increase with respect to previous achievements [18]. The highest output power in CW operation from an oscillator employing a ceramic gain medium and delivering a radially polarized beam was 60 W [19]. In pulsed operation, a maximum output power of 10.6 W with a pulse duration of 75 ps was achieved [20]. For both cases, the polarizing mechanism was based on a thermally induced bifocusing effect in the ceramic Nd:YAG rod. In the following, we present what we believe to be the first use of an intra-cavity circular grating-waveguide mirror (CGWM) in a TDL with a polycrystalline Yb:Lu2O3 ceramic disk to generate radially polarized beams. An output power of 175 W was achieved with beam propagation factors of M2hor. = 2.05 and M2ver. = 2.32 as measured in the horizontal and vertical direction, respectively, and a degree of radial polarization of 96.2%.

2 Experimental setup

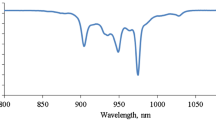

The experimental setup is illustrated in Fig. 1. A polycrystalline Yb:Lu2O3 ceramic disk with a radius of curvature of 3.7 m, a doping concentration of 4.4 at.%, a thickness of 120 ± 5 µm, and a diameter of 11.0 mm was used, which was pumped by a fiber-coupled diode laser. The disk was glued on a water-cooled diamond heat sink for efficient heat removal and mounted in a commonly used multipass TDL pumping module. The spectral bandwidth of the diode was broader than the width of 2.9 nm of the absorption line of Yb:Lu2O3 [13]. To minimize the risk of feeding the residual unabsorbed pump radiation back into the laser diode, the pumping module was used only in a forward direction with 12-passes at the disk, after which the remaining radiation was not fed back into the module. The diameter of the pump spot on the disk was set to 3.1 mm. The laser cavity was designed to support the LG*01 mode (M2 = 2) with a mode diameter of 2.5 mm centered on the pump spot. It is worth mentioning that the disk used in our experiments did not show any signs of intrinsic or thermally induced birefringence [16].

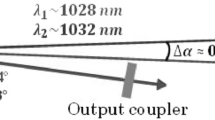

In order to generate a radially polarized beam, a CGWM was used as an end-cavity mirror. The used CGWM is identical to the one that was reported on in [21] and was designed to exhibit a reflectivity of 99.9% for radially polarized radiation (corresponding TM-polarization locally on the circular grating) and of 55.9% for azimuthally polarized radiation (TE-polarization with respect to the grating) at the wavelength of 1034 nm. The lower reflectivity was achieved thanks to the coupling of the corresponding radiation to TE leaky-modes of the multilayer mirror. The resulting difference between the reflectivities for radially and azimuthally polarized radiation was sufficient for the reliable suppression of azimuthally polarized modes in the resonator and resulted in the generation of a purely radially polarized output. The output coupling was chosen to be 4% and the cavity was designed with the possibility to easily integrate semiconductor saturable absorber mirror (SESAM) for mode-locking experiments by simply replacing the cavity end-mirror with a SESAM and some of the folding mirrors with Gires-Tournois-Interferometer mirrors in future work.

3 Experimental results

The black symbols in Fig. 2 show the measured output power (filled triangles) and the optical efficiency (empty triangles) for the radially polarized laser emission, that is obtained when the laser beam is centered on the CGWM. For comparison, the red symbols show the results of the unpolarized laser operation obtained when the laser beam was reflected on the unstructured part of the mirror (outside the grating structure), where the element simply acts as a standard highly reflective (HR) mirror. The maximum output power of the radially polarized beam of 175 W was achieved at 440 W of absorbed pump power. For the unpolarized operation, an output power of 203 W was measured at 447 W of absorbed pump power. The corresponding slope efficiencies were 45.5% and 51.7% for the radially polarized and the unpolarized operation, respectively. The highest optical efficiencies were measured to be 39.7% and 46.1% at 175 W and 183 W of output power for the radially polarized and the unpolarized operation, respectively. It is worth mentioning that the unabsorbed pump power that was left after the unidirectional path through the pumping module was measured to amount to about 120 W at the maximum output powers. The lower efficiency obtained in radial polarization is mainly attributed to the lower reflectivity of the CGWM as compared to that of the unstructured HR coating. Additionally, the pure radially polarized LG01-mode with its vanishing intensity in the center exhibits a smaller spatial overlap with the homogenously pumped area on the disk as compared to the standard superposition of Hermite–Gaussian modes of the unpolarized beam. At the maximum output power, the beam propagation factor was measured to be M2hor. = 2.05 and M2ver. = 2.32 in the horizontal and vertical directions, respectively. The obtained values are close to the theoretically expected value of M2 = 2 for a doughnut mode. Figure 3 shows the caustic of the radially polarized laser beam as measured using a beam profiler according to ISO 11146 at the maximum output power of 175 W. The insets show the intensity distributions of the emitted LG01-mode beam in the near and far-fields. Further increase of the power was limited by the onset of resonator instabilities.

The polarization of the output beam was analyzed qualitatively by recording the beams transmitted through a polarization beam splitter (PBS) mounted on a rotary stage with a CCD camera. Figure 4 shows the recorded intensity distributions at four different power levels and for three different orientations of the PBS. The white arrows indicate the polarization of the transmitted radiation. The well-separated lobes of the radiation transmitted through the PBS confirm a high degree of radial polarization. Using a home-built 2D-polarimeter [22], the degree of radial polarization was measured to be 96.2% at the maximum output power of 175 W.

Far-field intensity distributions of the emitted beams with and without polarization beam splitter placed in front of the camera at 12 W (a), 51 W (b), 101 W (c) and 175 W (d) of output power. The arrows indicate the direction of polarization of the radiation transmitted through the polarizing beam splitter

4 Summary and outlook

In conclusion, the generation of radially polarized beams was demonstrated using a circular GWM in an Yb:Lu2O3 ceramic thin-disk laser. An average output power of 175 W (corresponding to an optical efficiency of 39.6%) and a degree of radial polarization of 96.2% were achieved. To the best of our knowledge, this is the highest power demonstrated for radially polarized beams generated with a polycrystalline ceramic laser material. Further power scaling was limited by the onset of resonator instabilities. Further work will be dedicated to the implementation of a SESAM in the presented laser to generate ultra-short pulses with radial polarization. Further power scaling using a spectrally stabilized multi-kW pump diode will also be tested later on.

Data availability

The data that support the findings of this study are available from the corresponding author, M. A. Ahmed, upon reasonable request.

References

Q. Zhan, Adv. Opt. Photon. 1, 1 (2009)

Y. Kozawa, D. Matsunaga, S. Sato, Optica 5, 86 (2018)

M. Xian, Y. Xu, X. Ouyang, Y. Cao, S. Lan, X. Li, Sci. Bull. (Beijing) 65, 2072 (2020)

X. Li, T.-H. Lan, C.-H. Tien, M. Gu, Nat. Commun. 3, 998 (2012)

H. Kang, B. Jia, J. Li, D. Morrish, M. Gu, Appl. Phys. Lett. 96, 063702 (2010)

T. Häcker, in AKL International Laser Technology Congress (2016)

R. Weber, A. Michalowski, M. Abdou-Ahmed, V. Onuseit, V. Rominger, M. Kraus, T. Graf, Phys Procedia 12, 21 (2011)

M.A. Ahmed, M. Haefner, M. Vogel, C. Pruss, A. Voss, W. Osten, T. Graf, Opt Express 19, 5093 (2011)

A. Loescher, J.-P. Negel, T. Graf, M. Abdou Ahmed, Opt. Lett. 40, 5758 (2015)

F. Beirow, M. Eckerle, B. Dannecker, T. Dietrich, M.A. Ahmed, T. Graf, Opt. Express 26, 4401 (2018)

M. Abdou Ahmed, F. Beirow, A. Loescher, T. Dietrich, D. Bashir, D. Didychenko, A. Savchenko, C. Pruss, M. Fetisova, F. Li, P. Karvinen, M. Kuittinen, T. Graf, Nanophotonics 11, 835 (2022)

T. Dietrich, M. Rumpel, F. Beirow, C.M. Mateo, C. Pruss, W. Osten, M.A. Ahmed, T. Graf, Opt. Lett. 43, 1371 (2018)

R. Peters, C. Kränkel, S.T. Fredrich-Thornton, K. Beil, K. Petermann, G. Huber, O.H. Heckl, C.R.E. Baer, C.J. Saraceno, T. Südmeyer, U. Keller, Appl. Phys. B 102, 509 (2011)

V. Petrov, K. Petermann, U. Griebner, V. Peters, J. Liu, M. Rico, P. Klopp, G. Huber, Laser Source and System Technology for Defense and Security II (SPIE, 2006), p.62160H

C. Kränkel, IEEE J. Sel. Top. Quantum Electron. 21, 250 (2015)

S. Esser, X. Xu, T. Graf, M.A. Ahmed, in 2023 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, 2023. p. 1

W. Kim, C. Baker, G. Villalobos, J. Frantz, B. Shaw, A. Lutz, B. Sadowski, F. Kung, M. Hunt, J. Sanghera, J. Am. Ceram. Soc. 94, 3001 (2011)

S. Esser, C. Röhrer, X. Xu, J. Wang, J. Zhang, T. Graf, M.A. Ahmed, Opt. Lett. 46, 6063 (2021)

I. Moshe, S. Jackel, Y. Lumer, A. Meir, R. Feldman, Y. Shimony, Opt. Lett. 35, 2511 (2010)

H. Jianhong, D. Jing, C. Yongge, W. Wen, Z. Hui, L. Jinhui, S. Fei, G. Yan, D. Shutao, L. Wenxiong, Opt. Express 19, 2120 (2011)

T. Dietrich, M. Rumpel, F. Beirow, C.M. Mateo, C. Pruss, W. Osten, M. Abdou Ahmed, T. Graf, Opt. Lett. 43, 1371 (2018)

T. Liebig, M.A. Ahmed, A. Voss, T. Graf, in SPIE LASE Photonics West, San Francisco, 2010

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was supported by funding from the European Union's Horizon 2020 research and innovation program under the Marie Skłodowska-Curie Grant agreement No. 813159.

Author information

Authors and Affiliations

Contributions

DD designed and conducted the laser experiment and wrote the manuscript. SE and FB participated in the experiment preparation and build-up of the experimental setup. AS and CP supported in the production of the CGWM. MAA provided the design of CGWM and supported in the interpretation of the experimental results. TG and MAA assisted in the preparation of the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Didychenko, D., Esser, S., Beirow, F. et al. Generation of a radially polarized beam in a polycrystalline ceramic Yb:Lu2O3 thin-disk laser. Appl. Phys. B 129, 146 (2023). https://doi.org/10.1007/s00340-023-08089-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-023-08089-6