Abstract

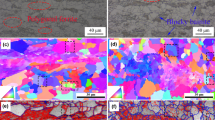

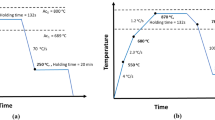

This study investigates the constitutive equation and microstructure evolution of an experimental Fe–26.6Mn–9.8Al–1.0C lightweight steel at deformation temperatures of 850–1050 °C and strain rates of 0.01–5 s−1 via thermal–mechanical simulation. The flow stress curves of the steel are modified by considering the effects of friction and temperature rise. A high-temperature constitutive equation of the lightweight alloy is expressed using Arrhenius-type equation involving the Zener–Hollomon parameter, the constitutive equation based on peak stress and strain compensation (material parameters vary with different strain) were constructed, respectively, which can better predict the flow stress changes of the experimental steel during hot compression, the average absolute relative error (AARE) and R were calculated to be 5.6% and 0.98. DRX kinetic model of the experimental steel was also established, and the results show that the high temperatures and low strain rates are conducive to DRX. DRX is sensitive to thermal deformation temperatures and strain rates, but the sensitivity to temperatures is higher than that to strain rates. Deformation twin and dislocation slipping are the main deformation mechanisms in the experimental steel at the low deformation temperature of 850 °C. At the higher temperature of 1050 °C, the deformation mechanisms are dislocation slipping and deformation banding.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Z. Li, Y.C. Wang, X.W. Cheng, J.X. Liang, S.K. Li, Compressive behavior of a Fe–Mn–Al–C lightweight steel at different strain rates. Mater. Sci. Eng. A 772, 138700 (2020)

H. Song, J. Yoo, S.H. Kim, S.S. Sohn, M. Koo, N.J. Kim, S. Lee, Novel ultra-high strength Cu-containing medium-Mn duplex lightweight steels. Acta. Mater. 135, 215–225 (2017)

S.P. Chen, R. Rana, A. Haldar, R.K. Ray, Current state of Fe–Mn–Al–C low density steels. Prog. Mater. Sci. 89, 345–391 (2017)

O.A. Zambrano, A general perspective of Fe–Mn–Al–C steels. J. Mater. Sci. 53, 14003–14062 (2018)

Z.Y. Huang, A.L. Hou, Y.S. Jiang, P. Wang, Q. Shi, Q.Y. Hou, X.H. Liu, Rietveld refinement, microstructure, mechanical properties and oxidation characteristics of Fe–28Mn–xAl–1C (x = 10 and 12 wt.%) low-density steels. J. Iron. Steel. Res. Int. 24, 1190–1198 (2017)

Z.Y. Huang, Y.S. Jiang, A.L. Hou, P. Wang, Q. Shi, Q.Y. Hou, X.H. Liu, Rietveld refinement, microstructure and high-temperature oxidation characteristics of low-density high manganese steels. J. Mater. Sci. Technol. 33, 1531–1539 (2017)

K.T. Park, Tensile deformation of low-density Fe–Mn–Al–C austenitic steels at ambient temperature. Scripta Mater. 68, 375–379 (2013)

I. Gutierrez-Urrutia, D. Raabe, Influence of Al content and precipitation state on the mechanical behaviour of austenitic high-Mn low-density steels. Scripta Mater. 68, 343–347 (2013)

E. Welsch, D. Ponge, S.M. Hafez Haghighat, S. Sandlöbes, P. Choi, M. Herbig, S. Zaefferer, D. Raabe, Strain hardening by dynamic slip band refinement in a high-Mn lightweight steel. Acta. Mater. 116, 188–199 (2016)

C.L. Lin, C.G. Chao, J.Y. Juang, J.M. Yang, T.F. Yang, Deformation mechanisms in ultrahigh-strength and high-ductility nanostructured FeMnAlC alloy. J. Alloy Compd. 586, 616–620 (2014)

K.M. Chang, C.G. Chao, T.F. Liu, Excellent combination of strength and ductility in a Fe–9Al–28Mn–1.8C alloy. Scripta Mater. 63, 162–165 (2010)

I. Gutierrez-Urrutia, D. Raabe, High strength and ductile low density austenitic FeMnAlC steels: simplex and alloys strengthened by nanoscale ordered carbides. Mater. Sci. Tech-Lond. 30, 1099–1104 (2014)

A. Prosviryakov, B. Mondoloni, A. Churyumov, A. Pozdniakov, Microstructure and hot deformation behaviour of a novel Zr-alloyed high-Boron steel. Metals-Basel. 9, 218 (2019)

A.Y. Churyumov, A.V. Pozdnyakov, T.A. Churyumova, Hot plastic deformation of heat-resistant austenitic aisi 310s steel. Part 1. simulation of flow stress and dynamic recrystallization. Chernye Met. 2020, 48–55 (2020)

R.H. Yu, P.C. Wang, G.S. Li, M. Fang, G.S. Xu, M.Y. Zhang, Correction and modeling of flow stress during hot deformation of 7055 aluminium alloy. J. Mater. Eng. Perform. 31, 6870–6879 (2022)

R.H. Yu, X. Li, W.J. Li, J.T. Chen, X. Guo, J.H. Li, Application of four different models for predicting the high-temperature flow behavior of TG6 titanium alloy. Mater. Today Commun. 26, 102004 (2021)

Q.M. Yang, Y.C. Lin, M.S. Chen, Z.J. Chen, Modeling dynamic recrystallization behavior in a novel HIPed P/M superalloy during high-temperature deformation. Materials 15(11), 4030 (2022)

Y.P. Li, R.B. Song, E.D. Wen, F.Q. Yang, Hot deformation and dynamic recrystallization behavior of austenite-based low-density Fe–Mn–Al–C steel. Acta Metall. Sin-Engl. 29, 441–449 (2016)

F.Q. Yang, R.B. Song, L.F. Zhang, C. Zhao, Hot deformation behavior of Fe-Mn-Al light-weight steel. Procedia Eng. 81, 456–461 (2014)

A.Y. Churyumov, A.A. Kazakova, A.V. Pozdniakov, T.A. Churyumova, A.S. Prosviryakov, Investigation of hot deformation behavior and microstructure evolution of lightweight Fe–35Mn–10Al–1C steel. Metals-Basel 12(5), 831 (2022)

A.R. Kalantaria, A.Z. Hanzaki, H.R. Abediba, M.S. Jalali, S.-J. Park, J.Y. Park, The high temperature deformation behavior of a Triplex (ferrite+ austenite+ martensite) low density steel. J. Mater. Res. Technol. 13, 1388–1401 (2021)

S.Y. Jiang, Y. Wang, Y.Q. Zhang, X.D. Xing, B.Y. Yan, Constitutive behavior and microstructural evolution of FeMnSiCrNi shape memory alloy subjected to compressive deformation at high temperatures. Mater. Des. 182, 108019 (2019)

H.M. Zhang, G. Chen, Q. Chen, F. Han, Z.D. Zhao, A physically-based constitutive modelling of a high strength aluminum alloy at hot working conditions. J. Alloy Comp. 743, 283–293 (2018)

R.B. Mei, L. Bao, F. Huang, X. Zhang, X.W. Qi, X.H. Liu, Simulation of the flow behavior of AZ91 magnesium alloys at high deformation temperatures using a piecewise function of constitutive equations. Mech. Mater. 125, 110–120 (2018)

G.L. Ji, L. Li, F.L. Qin, L.Y. Zhu, Q. Li, Comparative study of phenomenological constitutive equations for an as-rolled M50NiL steel during hot deformation. J. Alloy Comp. 695, 2389–2399 (2017)

D.G. Liu, H. Ding, X. Hu, H. Dong, M.H. Cai, Dynamic recrystallization and precipitation behaviors during hot deformation of a k-carbide-bearing multiphase Fe–11Mn–10A1–0.9C lightweight steel. Mater. Sci. Eng. A 772, 138682 (2020)

H.T. Lu, D.Z. Li, S.Y. Li, Y.A. Chen, Hot deformation behavior of Fe–27.34Mn–8.63Al–1.03C lightweight steel. Int. J. Miner. Metall. Mater. 30, 734–743 (2023)

L.Y. Qian, G. Fang, P. Zeng, L.X. Wang, Correction of flow stress and determination of constitutive constants for hot working of API-X100 pipeline steel. Int. J. Pres. Ves. Pip. 133, 43–51 (2015)

X.P. Liang, Y. Liu, H.Z. Li, C.X. Zhou, G.F. Xu, Constitutive relationship for high temperature deformation of powder metallurgy Ti–47Al–2Cr–2Nb–0.2W alloy. Mater. Des. 37, 40–47 (2012)

L. Li, J. Zhou, J. Duszczyk, Determination of a constitutive relationship for AZ31B magnesium and validation through comparison between simulated and real extrusion. J. Mater. Process. Tech. 172, 372–380 (2006)

J.C. Long, Q.X. Xia, G.F. Xiao, Y. Qin, S. Yuan, Flow characterization of magnesium alloy ZK61 during hot deformation with improved constitutive equations and using activation energy maps. Int. J. Mech. Sci. 191, 106069 (2020)

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, L.T. Li, EBSD study of a hot deformed nickel-based superalloy. J. Alloy Compd. 640, 101–113 (2015)

Q.M. Yang, Y.C. Lin, J.Z. Guo, C. Wang, Z.J. Chen, K.G. Chen, J.C. Zhu, Spheroidization and dynamic recrystallization mechanisms of a novel HIPed P/M superalloy during hot deformation. J. Alloy Compd. 910, 164909 (2022)

W.J. Wang, T.H. Man, M. Zhang, Y. Wang, H. Dong, δ-ferrite dynamic recrystallization behavior during thermal deformation in Fe–32Mn–11Al–0.9 C low density steel. J. Mater. Res. Technol. 18, 1345–1357 (2022)

J. Rasti, A. Najafizadeh, M. Meratian, Correcting the stress-strain curve in hot compression test using finite element analysis and Taguchi method. Int. J. ISSI. 8, 26–33 (2011)

H.R. Abedi, A.Z. Hanzaki, Z. Liu, R. Xin, N. Haghdadi, P.D. Hodgson, Continuous dynamic recrystallization in low density steel. Mater. Des. 114, 55–64 (2017)

C. Zener, J.H. Hollomon, Effect of strain-rate upon the plastic flow of steel. Jpn. J. Appl. Phys. 15, 22–32 (1944)

Y.C. Lin, M.S. Chen, J. Zhong, Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comp. Mater. Sci. 42, 470–477 (2008)

G.B. Wei, X.D. Peng, F.P. Hu, A. Hadadzadeh, Y. Yang, W.D. Xie, M.A. Wells, Deformation behavior and constitutive model for dual-phase Mg–Li alloy at elevated temperatures. Trans. Nonferrous Met. Soc. China 26, 508–518 (2016)

Y.H. Sun, B. Yang, F. Zhang, R.H. Wang, C.Q. Peng, J. Ren, G.S. Song, Hot deformation behavior of Mg–5Li–3Al–2Zn–0.2 Zr alloy based on constitutive analysis, processing map, and microstructure evolution. J. Alloys Compd. 941, 168983 (2023)

N. Zhao, Q. Sun, Q. Pang, Z.L. Hu, Comprehensive study of hot compression behaviors and microstructure evolution of solutionized 6082 aluminum alloy extruded bar. J. Alloys Compd. 931, 167541 (2023)

Y. Han, G.J. Qiao, Y. Sun, D.N. Zou, Modeling the constitutive relationship of Cr20Ni25Mo4Cu superaustenitic stainless steel during elevated temperature. Mater. Sci. Eng. A 539, 61–67 (2012)

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, K.V. Kasiviswanathan, Constitutive equations to predict high temperature flow stress in a Ti-modified austenitic stainless steel. Mater. Sci. Eng. A 500, 114–121 (2009)

M.E. Mehtedi, F. Musharavati, S. Spigarelli, Modelling of the flow behaviour of wrought aluminium alloys at elevated temperatures by a new constitutive equation. Mater. Des. 54, 869–873 (2014)

S. Spigarelli, M.E. Mehtedi, A new constitutive model for the plastic flow of metals at elevated temperatures. J. Mater. Eng. Perform. 23, 658–665 (2014)

G.L. Wu, C.Y. Zhou, X.B. Liu, Dynamic recrystallization behavior and kinetics of high strength steel. J. Cent. South Univ. 23, 1007–1014 (2016)

B.J. Lv, J. Peng, Y.L. Wang, X.Q. An, L.P. Zhong, A.T. Tang, F.S. Pan, Dynamic recrystallization behavior and hot workability of Mg–2.0Zn–0.3Zr–0.9Y alloy by using hot compression experimental. Mater. Des. 53, 357–365 (2014)

H.Z. Li, H.J. Wang, Z. Li, C.M. Liu, H.T. Liu, Flow behavior and processing map of as cast Mg-10Gd-48Y-2Zn-0.6Zr alloy. Mater. Sci. Eng. A 528, 154–160 (2010)

J.J. Jonas, X. Quelennec, L. Jiang, E. Martin, The Avrami kinetics of dynamic recrystallization. Acta. Mater. 57, 2748–2756 (2009)

C. Zhang, L.W. Zhang, W.F. Shen, C.R. Liu, Y.N. Xia, R.G. Li, Study on flow stress modeling and processing maps for hot deformation of medium carbon Cr–Ni–Mo alloyed steel. Mater. Des. 90, 804–814 (2016)

H.L. Wei, G.Q. Liu, X. Xiao, M.H. Zhang, Dynamic recrystallization behavior of a medium carbon vanadium microalloyed steel. Mater. Sci. Eng. A 573, 215–221 (2013)

M. Shaban, B. Eghbali, Determination of critical conditions for dynamic recrystallization of a microalloyed steel. Mater. Sci. Eng. A 527, 4320–4325 (2010)

J.K. Kim, B.C. Decooman, Stacking fault energy and deformation mechanisms in Fe–xMn–0.6C–yAl TWIP steel. Mater. Sci. Eng. A 676, 216–231 (2016)

W.W. Song, T. Ingendahl, W. Bleck, Control of strain hardening behavior in high-Mn austenitic steels. Acta Metall. Sin-Engl. 27, 546–556 (2014)

O.A. Zambrano, J. Valdes, Y. Aguilar, J.J. Coronado, S.A. Rodriguez, R.E. Loge, Hot deformation of a Fe–Mn–Al–C steel susceptible of κ-carbide precipitation. Mater. Sci. Eng. A 689, 269–285 (2017)

K.T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, C.S. Lee, Stacking fault energy and plastic deformation of fully austenitic high manganese steels: effect of Al addition. Mater. Sci. Eng. A 527, 651–3661 (2010)

Acknowledgements

The research reported in this paper is financially supported by the National Natural Science Foundation of China (Grant No. 51674004), National Natural Science Foundation Youth Foundation of China (Grant No. 51805002), Anhui Provincial Natural Science Research Key Program of Higher Education Institutions (Grant No. 2022AH051760), Key Laboratory of Construction Hydraulic Robots of Anhui Higher Education Institutes, Tongling University (Grant No. TLXYCHR-O-21YB03).

Funding

This study was funded by the National Natural Science Foundation of China (Grant No. 51674004), National Natural Science Foundation Youth Foundation of China (Grant No. 51805002), Anhui Provincial Natural Science Research Key Program of Higher Education Institutions (Grant No. 2022AH051760), Key Laboratory of Construction Hydraulic Robots of Anhui Higher Education Institutes, Tongling University (Grant No. TLXYCHR-O-21YB03).

Author information

Authors and Affiliations

Contributions

Under supervision by JL and ZH, JS performed sample preparation, data analysis and calculations. PW performed sample preparation and structure fabrication. The first draft of the manuscript was written by JS and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

All participating authors announced no conflict of interest in this work. We solemnly declare no existing conflicts of interest, such as commercial or affiliated interests with the submitted work.

Ethical approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki declaration and its later amendments or comparable ethical standards

Informed consent

Informed consent was obtained from all individual participants included in the study.

Consent for publication

Consent for publication was obtained for every individual person’s data included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, J., Li, J., Huang, Z. et al. Constitutive equation and microstructure evolution during isothermal compression of an Fe–26.6Mn–9.8Al–1.0C lightweight steel. Appl. Phys. A 129, 529 (2023). https://doi.org/10.1007/s00339-023-06812-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06812-w