Abstract

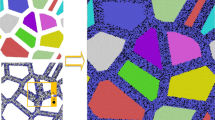

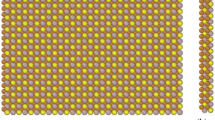

Molecular dynamics (MD) simulation is carried out to analyze the titanium content effect on the deformation behaviors in nanocrystalline (NC) Ni–Ti alloy with alloy atoms segregated in grain boundary affect zone (GBAZ). The GBAZ is generated by equidistance scaling of the vertices of a polygon using an isometric entity command. The MD simulation indicates that the fracture toughness and tensile strength of NC Ni–Ti alloy can be obviously enhanced by augmenting the titanium content. This corresponding deformation mechanisms about the enhanced fracture toughness through enlarging the titanium content are explored in detail. Furthermore, the influence of columnar particles on the mechanical behaviors of NC Ni–Ti alloy is studied. At the same time, the pinning mechanism of columnar particles on GBAZ of the matrix phase is analyzed.

Similar content being viewed by others

Data Availability Statement

The data that support the findings of this study are available upon reasonable request from the authors.

References

I. Darwin Immanuel, M. Gangaraju, D. Arulkirubakaran, R. Malkiya Rasalin Prince, T. Debnath, D. Palanisamy, (2022) Fabrication, mechanical testing, machining of shape memory alloy-A review, Materials Today: Proceedings.

S. Sampath, Influence of copper on the deformation behavior of NiTi shape memory alloys in isothermal compression, Materials Today: Proceedings (2022).

T. Rabczuk, T. Belytschko, Cracking particles: a simplified meshfree method for arbitrary evolving cracks, World Congress on Computational Mechanics, 2004.

Y. Zhang, H.A. Mang, Global cracking elements: a novel tool for Galerkin-based approaches simulating quasi-brittle fracture, 2019.

T. Rabczuk, G. Zi, S. Bordas, H. Nguyen-Xuan, A simple and robust three-dimensional cracking-particle method without enrichment. Comput. Methods Appl. Mech. Eng. 199, 2437–2455 (2010)

Y. Zhang, R. Lackner, M. Zeiml, H.A. Mang, Strong discontinuity embedded approach with standard SOS formulation: Element formulation, energy-based crack-tracking strategy, and validations. Comput. Methods Appl. Mech. Eng. 287, 335–366 (2015)

Y. Zhang, X. Zhuang, Cracking elements: a self-propagating strong discontinuity embedded approach for quasi-brittle fracture. Finite Elem. Anal. Des. 144, 84–100 (2018)

Y. Zhang, Z. Gao, Y. Li, X. Zhuang, On the crack opening and energy dissipation in a continuum based disconnected crack model. Finite Elem. Anal. Des. 170, 103333 (2020)

Y. Zhang, J. Huang, Y. Yuan, H.A. Mang, Cracking elements method with a dissipation-based arc-length approach. Finite Elem. Anal. Des. 195, 103573 (2021)

Y. Zhang, X. Zhuang, Cracking elements method for dynamic brittle fracture. Theoret. Appl. Fract. Mech. 102, 1–9 (2019)

Y. Zhang, X. Yang, X. Wang, X. Zhuang, A micropolar peridynamic model with non-uniform horizon for static damage of solids considering different nonlocal enhancements. Theoret. Appl. Fract. Mech. 113, 102930 (2021)

Y. Zhang, Z. Gao, X. Wang, Q. Liu, Predicting the pore-pressure and temperature of fire-loaded concrete by a hybrid neural. Network 19, 2142011 (2022)

Y. Zhang, Z. Gao, X. Wang, Q.J. Liu, Image representations of numerical simulations for training neural networks. Compu.r Model. Eng. Sci (2023). https://doi.org/10.32604/cmes.2022.022088

H.W. Xiaoyang Yi, K. Sun, W. Gao et al., Characterization of high-strength Ti–Ni shape memory alloys prepared by hot pressed sintering. J Alloys Comp. 854, 157159 (2021)

G.S. Xiaoyang Yi, X. Meng, H. Wang et al., The higher compressive strength (TiB+La2O3)_Ti–Ni shape memory alloy composite with the larger recoverable strain. Compos. Commun 23, 100583 (2021)

R.Z.V. I.A. Ovid’ko, Y.T. Zhu, Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci 94, 462–540 (2018)

G. Li, F. Zhang, D. Zhu, L. Wang, Segregation thickness effect on the mechanical behaviors of nanocrystalline Ni-doped W alloy. Phys. Lett. A 409, 127513 (2021)

X. Shi, J. Li, W. Tang, J. Zhang, Effect of grain size on Lüders-type deformation and plastic deformation of V nanowires/NiTi composites. Mater. Charact. 194, 112388 (2022)

G.L. Feng Zhang, D. Zhu, J. Zhou, Grain size effect on the mechanical behaviors in nanocrystalline Cu-Ag alloy with grain boundary affect zone segregation. Mater. Lett 278, 128406 (2020)

F.C. Zhifu Zhao, Y. Wei, Atomistic scale behaviors of crack propagation in nanocrystalline bcc iron. Mater Sci Eng A. 809, 140948 (2021)

N. Vu-Bac, T. Lahmer, H. Keitel, J. Zhao, X. Zhuang, T.J.M.o.M. Rabczuk, Stochastic predictions of bulk properties of amorphous polyethylene based on molecular dynamics simulations. Mech. Mater. 68, 70–84 (2014)

N. Vu-Bac, T. Lahmer, Y. Zhang, X. Zhuang, T. Rabczuk, Stochastic predictions of interfacial characteristic of polymeric nanocomposites (PNCs). Compos. B 59, 80–95 (2014)

N.S. Vu-Bac, M. Lahmer, T. Zhuang, X. Rabczuk, T., %J Computational Materials Science a unified framework for stochastic predictions of mechanical properties of polymeric nanocomposites. Computat. Mater. Sci. 96, 520–535 (2015)

N. Vu-Bac, R. Rafiee, X. Zhuang, T. Lahmer, T.J.C. Rabczuk, Uncertainty quantification for multiscale modeling of polymer nanocomposites with correlated parameters. Compos. Part B: Eng. (2015). https://doi.org/10.1016/j.compositesb.2014.09.008

N. Vu-Bac, T. Lahmer, X. Zhuang, Nguyen-Thoi, R.J.A.i.E., Software, A software framework for probabilistic sensitivity analysis for computationally expensive models. Adv. Eng Software 100, 19–31 (2016)

N. Vu-Bac, X. Zhuang, T.J.M. Rabczuk, Uncertainty quantification for mechanical properties of polyethylene based on fully atomistic model. Materials 12, 3613 (2019)

B. Liu, N. Vu-Bac, X. Zhuang, T.J.M.o.M. Rabczuk, Stochastic multiscale modeling of heat conductivity of Polymeric clay nanocomposites. Mech. Mater. 142, 103280 (2020)

B. Liu, N. Vu-Bac, T.J.C.S. Rabczuk, A stochastic multiscale method for the prediction of the thermal conductivity of Polymer nanocomposites through hybrid machine learning algorithms. Compos. Struct. 273, 114269 (2021)

B. Liu, N. Vu-Bac, X. Zhuang, X. Fu, T.J.C.s. Rabczuk, Stochastic full-range multiscale modeling of thermal conductivity of Polymeric carbon nanotubes composites: a machine learning approach. Compos. Struct. (2022). https://doi.org/10.1016/j.compstruct.2022.115393

B. Liu, N. Vu-Bac, X. Zhuang, X. Fu, T. Rabczuk, Stochastic integrated machine learning based multiscale approach for the prediction of the thermal conductivity in carbon nanotube reinforced polymeric composites. Compos. Sci. Technol. 224, 109425 (2022)

N. Pant, S. Das, P. Bellon, R.S. Averback, M. Krief, Y. Ashkenazy, Role of interfaces on phase formation during severe plastic deformation. Acta Mater. 240, 118333 (2022)

N.V. Nirab Pant, Y. Ashkenazy, P. Bellon, R.S. Averback, Phase evolution in two-phase alloys during severe plastic deformation. Acta Mater. 210, 116826 (2021)

F. Zhang, G. Li, J. Zhou, Deformation mechanism of bimodal nanotwinned Cu-Ag alloy with grain boundary affect zone segregation. Mater. Today Commun. 29, 102856 (2021)

R.S. Zengin, V. Sezer, A novel point inclusion test for convex polygons based on Voronoi tessellations. Appl. Math. Comput. 399, 126001 (2021)

H.M.A. Aidan, P. Thompson, R. Berger, D.S. Bolintineanu et al., LAMMPS - a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 108171 (2022)

N. Vu-Bac, M.A. Bessa, T. Rabczuk, W.K.J.M. Liu, A multiscale model for the quasi-static thermo-plastic behavior of highly cross-linked glassy polymers. Macromolecules 48(18), 6713–6723 (2015)

N. Vu-Bac, P. Areias, T.J.P. Rabczuk, A multiscale multisurface constitutive model for the thermo-plastic behavior of polyethylene. Polymers 105, 327–338 (2016)

M. Jbeili, J. Zhang, The generalized periodic boundary condition for microscopic simulations of heat transfer in heterogeneous materials. Int. J. Heat Mass Transf. 173, 121200 (2021)

K. Zhou, B. Liu, Chapter 3 - Control techniques of molecular dynamics simulation, in: K. Zhou, B. Liu (Eds.), Molecular Dynamics Simulation, Elsevier2022, pp. 67–96.

W.Z. Polak, Efficiency in identification of internal structure in simulated monoatomic clusters: comparison between common neighbor analysis and coordination polyhedron method. Comput. Mater. Sci. 201(2022), 110882 (2022)

W.Z. Polak, Efficiency in identification of internal structure in simulated monoatomic clusters: comparison between common neighbor analysis and coordination polyhedron method. Comput. Mater. Sci. 201, 110882 (2022)

L. Wang, X. Liang, B. Liu, M. Oehring, J. Paul, J. Liu, M. Song, F. Pyczak, Y. Liu, Stacking fault formation in perovskite Ti3AlC carbides in a TiAl based alloy during creep at 800°C. Scripta Mater. 222, 115034 (2023)

L. Bin, X. Liao, B. Geng, Q. Zhu, M. Yu, J. Li, K. Liu, D. Jia, Z. Yang, Y. Zhou, A pinning effect for the enhanced oxidation resistance at 1600 °C of silicoboron carbonitride ceramics with the addition of MXene. Corros. Sci. 196, 110041 (2022)

Acknowledgements

This project was supported by the National Natural Science Foundation of China (52005248), Scientific research fund project of Nanjing Institute of Technology (CKJA202101), Natural Science Foundation of Jiangsu Province (BK20201031).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, G., Wang, R., Zhang, F. et al. Titanium content and columnar particles effect on the deformation behaviors of nanocrystalline Ni–Ti alloy with GBAZ segregation. Appl. Phys. A 129, 152 (2023). https://doi.org/10.1007/s00339-023-06437-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06437-z