Abstract

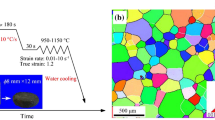

This study is dedicated to investigate the flow characteristics and processability of forged F92 stainless steel based on the results of isothermal compression test at temperatures of 1023–1423 K and strain rate of 0.01–10 s−1. Arrhenius constitutive equation was selected to analyze the flow stress curve. On account of the energy dissipation and instability criterion, the hot working map was constructed to determine the optimal deformation parameters, and their influence on microstructure evolution was also revealed. The trend of the flow stress curves were described using the strain factor, while with the increase in strain, the flow stress curve shows three types of changing trends, namely flow softening, hardening behavior and dynamic equilibrium between hardening and softening. The constitutive equation makes the flow stress predictable under all deformation conditions. Combined with the hot processing map and EBSD observation, the main deformation mechanism is analyzed as the dynamic recrystallization and flow localization in different deformation zones, and the best processing window of the steel was determined as the conditions of strain rate of 0.01 ~ 0.1 s−1, temperature range of 1223–1323 K.

Similar content being viewed by others

References

Y. Yamamoto, M.P. Brady, Z. Lu et al., Creep-resistant, Al2O3-forming austenitic stainless steels. Science 316, 433–436 (2007)

Y. Yamamoto, M.P. Brady, Z. Lu, C.T. Liu, M. Takeyama, P.J. Maziasz, B.A. Pint, Alumina-forming austenitic stainless steels strengthened by laves phase and MC carbide precipitates. Metall. Mater. Trans. A 38, 2737–2746 (2007)

Q. Gao, F. Qu, H. Zhang, Q. Huo, Austenite grain growth in alumina-forming austenitic steel. J. Mater. Res. 31, 1732–1740 (2016)

M.P. Brady, J. Magee, Y. Yamamoto, D. Helmick, L. Wang, Co-optimization of wrought alumina-forming austenitic stainless steel composition ranges for high-temperature creep and oxidation/corrosion resistance. Mater. Sci. Eng. A 590, 101–115 (2014)

J. Moon, T. Lee, Y. Heo, Y. Han, J. Kang, H. Ha, D. Suh, Precipitation sequence and its effect on age hardening of alumina-forming austenitic stainless steel. Mater. Sci. Eng. A 645, 72–81 (2015)

M.P. Brady, G. Muralidharan, Y. Yamamoto, B.A. Pint, Development of 1100 C capable alumina-forming austenitic alloys. Oxid. Met. 87, 1–10 (2016)

H.J. McQueen, S. Yue, N.D. Ryan, E. Fry, Hot working characteristics of steels in austenitic state. J. Mater. Process Tech. 53, 293–310 (1995)

Q. Gao, Y. Wang, M. Gong, F. Qu, X. Lin, Nonisothermal austenitic transformation kinetics in Fe-10Cr-1Co alloy. Appl. Phys. A 122, 1–10 (2016)

Y. Yamamoto, G. Muralidharan, M.P. Brady, Development of L12-ordered Ni3(Al, Ti)-strengthened aluminaforming austenitic stainless steel alloys. Scripta Mater. 69, 816–819 (2013)

G. Trotter, G. Rayner, I. Baker, P.R. Munroe, Accelerated precipitation in the AFA stainless steel Fe-20Cr-30Ni-2Nb-5Al via cold working. Intermetallics 53, 120–128 (2014)

D. Wang, H. Kahn, F. Ernst, A.H. Heuer, NiAl precipitation in delta ferrite grains of 17–7 precipitation-hardening stainless steel during low-temperature interstitial hardening. Scripta. Mater. 108, 136–140 (2015)

M.-H. Jang, J.-Y. Kang, J.H. Jang, T.-H. Lee, C. Lee, Hot deformation behavior and microstructural evolution of alumina-forming austenitic heat-resistant steels during hot compression. Mater. Charact. 123, 207–217 (2017)

A.S. Hamada, M.C. Somani, L.P. Karjalainen, High temperature flow stress and recrystallization behavior of high-Mn TWIP steels. ISIJ Int. 47, 907–912 (2007)

A. Dehghan-Manshadi, M.R. Barnett, P.D. Hodgson, Hot deformation and recrystallization of austenitic stainless steel: part I. Dynamic recrystallization. Metall. Mater. Trans. A 39, 1359–1370 (2008)

S. Banerjee, P.S. Robi, A. Srinivasan, L. Praveen Kumar, High temperature deformation behavior of Al-Cu-Mg alloys micro-alloyed with Sn. Mater. Sci. Eng. A 527, 2498–2503 (2010)

H. Mirzadeh, A simplified approach for developing constitutive equations for modeling and prediction of hot deformation flow stress. Metall. Mater. Trans. A 46(9), 4027–4037 (2015)

H. Mirzadeh, Constitutive modeling and prediction of hot deformation flow stress under dynamic recrystallization conditions. Mech. Mater. 85, 66–79 (2015)

H.J. McQueen, Elevated-temperature deformation at forming rates of 10–2 to 102 s-1. Metall. Mater. Trans. A 33, 345–362 (2002)

H. Mirzadeh, A. Najafizadeh, M. Moazeny, Flow curve analysis of 17–4 PH stainless steel under hot compression test. Metall. Mater. Trans. A 40, 2950–2958 (2009)

S.V. Mehtonen, L.P. Karjalainen, D.A. Porter, Hot deformation behavior and microstructure evolution of a stabilized high-Cr ferritic stainless steel. Mater. Sci. Eng. A 571, 1–12 (2013)

E. Pu, W. Zheng, J. Xiang, Z. Song, J. Li, Hot deformation characteristic and processing map of superaustenitic stainless steel S32654. Mater. Sci. Eng. A 598, 174–182 (2014)

A. Momeni, K. Dehghani, Hot working behavior of 2205 austenite-ferrite duplex stainless steel characterized by constitutive equations and processing maps. Mater. Sci. Eng. A 528, 1448–1454 (2011)

A.S. Hamada, L.P. Karjalainen, M.C. Somani, The influence of aluminum on hot deformation behavior and tensile properties of high-Mn TWIP steels. Mater. Sci. Eng. A 467, 114–124 (2007)

D. Ponge, G. Gottstein, Necklace formation during dynamic recrystallization: mechanisms and impact on flow behavior. Acta. Mater. 46, 69–80 (1998)

A. Belyakov, K. Tsuzaki, H. Miura, T. Sakai, Effect of initial microstructures on grain refinement in a stainless steel by large strain deformation. Acta. Mater. 51, 847–861 (2003)

S. Mandal, A.K. Bhaduri, V. Subramanya Sarma, A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel. Metall. Mater. Trans. A 42, 1062–1072 (2010)

Y.C. Lin, X.-Y. Wu, X.-M. Chen, J. Chen, D.-X. Wen, J.-L. Zhang, L.-T. Li, EBSD study of a hot deformed nickel-based superalloy. J. Alloy Compd. 640, 101–113 (2015)

D. Raabe, Microstructure and crystallographic texture of strip-cast and hot-rolled austenitic stainless steel. Metall. Mater. Trans. A 26, 991–998 (1995)

Z. Savaedi, R. Motallebi, H. Mirzadeh, A review of hot deformation behavior and constitutive models to predict flow stress of high-entropy alloys. J. Alloy Compd. 903, 163964 (2022)

R. Motallebi, Z. Savaedi, H. Mirzadeh, Additive manufacturing – A review of hot deformation behavior and constitutive modeling of flow stress. Curr. Opin. Solid St. M 26(3), 100992 (2022)

M. El Wahabi, L. Gavard, J.M. Cabrera, J.M. Prado, F. Montheillet, EBSD study of purity effects during hot working in austenitic stainless steels. Mater. Sci. Eng. A 393, 83–90 (2005)

A. Dehghan-Manshadi, M.R. Barnett, P.D. Hodgson, Hot deformation and recrystallization of austenitic stainless steel: part II. Post-deformation recrystallization. Metall. Mater. Trans. A 39, 1371–1381 (2008)

Y. Tian, H. Huang, G. Yuan, W. Ding, Microstructure evolution and mechanical properties of quasicrystal-reinforced Mg-Zn-Gd alloy processed by cyclic extrusion and compression. J. Alloy Compd. 626, 42–48 (2015)

S. Gourdet, F. Montheillet, An experimental study of the recrystallization mechanism during hot deformation of aluminium. Mater. Sci. Eng. A 283, 274–288 (2000)

A. Belyakov, T. Sakai, R. Kaibyshev, New grain formation during warm deformation of ferritic stainless steel. Metall. Mater. Trans. A 29, 161–167 (1998)

Y. Prasad, T. Seshacharyulu, Modelling of hot deformation for microstructural control. Int. Mater. Rev. 43(6), 243–258 (1998)

Acknowledgements

The authors would like to express their sincere thanks for the research grants supported by the National Natural Science Foundation of China (Grant No.51805002), Project supported by the Research Fund of Key Laboratory of advanced metal material green preparation and surface technology (AHUT), Ministry of Education, China (Grant No.GFST2020KF03) and Postdoctoral Fund from Jiangsu Province and Anhui Province (Grant No. 2019K208 and No. 2019B343).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All participating authors declare that they have no conflict of interest in this work. We once again solemnly declare that there is no conflict of interest with the submitted work, such as commercial interest or ancillary interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wen, C., Pan, H. & Li, J. Flow characterization and microstructure evolution of high-temperature steel F92 during hot deformation. Appl. Phys. A 128, 949 (2022). https://doi.org/10.1007/s00339-022-06033-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-06033-7