Abstract

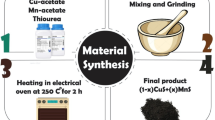

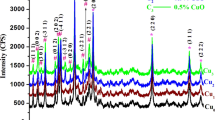

Nanocomposites of CdS@CuS heterostructures were synthesized applying a simple chemical procedure. The structural characteristics of resulting nanocomposites (1 − x)CdS–xCuS (x = 0, 0.3, 0.5, 0.7 and 1) samples were inferred applying synchrotron X-ray diffraction (XRD), Fourier transform infrared (FTIR) and high-resolution transmission electron microscope techniques. The optical characteristics were deduced from the UV–Vis and photoluminescence (PL) spectroscopy techniques. XRD phase identification revealed CuS having the hexagonal phase P 63/m m c, while CdS in two phases: cubic major phase \( F \bar{4} 3 m \) and hexagonal minor phase P 63 m c. The phase percentage, the crystallite size, the lattice parameters and the ions coordinates of each phase are traced as a function of the alloying parameter (x). FTIR analysis revealed a change in the transmittance intensity of the vibration bands upon changing CdS/CuS ration in the nanocomposites matrix. UV–Vis absorption spectra were affected greatly by the ratio of CdS to CuS in the different composites. All composites materials exhibited two energy gaps lower than parent compounds. The PL emission of CdS sample is broader than CuS sample. The PL spectra of CdS@CuS nanocomposites samples revealed a broad emission with a redshift depending on the ratio between CdS and CuS in the matrix. All samples emitted UV, violet and blue colors, while CuS sample reveals UV and violet colors. The obtained properties of CdS@CuS nanocomposites, by changing the composition ratio, make them good candidates for enhanced visible light photocatalytic activity and solar energy applications.

Similar content being viewed by others

References

Y.-X. Pan, Y. You, S. Xin, Y. Li, G. Fu, Z. Cui, Y.L. Men, F.F. Cao, S.H. Yu, J.B. Goodenough, J. Am. Chem. Soc. 139, 4123 (2017)

T. Jiang, Y. Wang, D. Meng, X. Wu, J. Wang, J. Chen, Appl. Surf. Sci. 311, 602 (2014)

Y. Wang, T. Jiang, D. Meng, J. Yang, Y. Li, Q. Ma, J. Han, Appl. Surf. Sci. 317, 414 (2014)

Z.K. Heiba, M.B. Mohamed, N.Y. Mostafa, Appl. Phys. A 125(2), 132 (2019)

K.P. Acharya, Photocurrent Spectroscopy of CdS/Plastic, CdS/Glass, and ZnTe/GaAs Hetero-pairs Formed with Pulsed-Laser Deposition, Ph.D. Thesis, Bowling Green State University, 2009

S.K. Apte, S.N. Garaje, G.P. Mane, A. Vinu, S.D. Naik, D.P. Amalnerkar, B.B. Kale, Small 7, 957 (2011)

L. Cheng, Q. Xiang, Y. Liao, H. Zhang, Energy Environ. Sci. 11, 1362 (2018)

N. Jiang, Z. Xiu, Z. Xie, H. Li, G. Zhao, W. Wang, Y. Wu, X. Hao, New J. Chem. 38, 4312 (2014)

Y.-X. Pan, J.B. Peng, S. Xin, Y. You, Y.L. Men, F. Zhang, M.Y. Duan, Y. Cui, Z.Q. Sun, J. Song, A.C.S. Sustain, Chem. Eng. 5, 5449 (2017)

Y. Shi, H. Li, L. Wang, W. Shen, H. Chen, A.C.S. Appl, Mater. Interfaces 4, 4800 (2012)

I. Ibrahim, H.N. Lim, O.K. Abou-Zied, N.M. Huang, P. Estrela, A. Pandikumar, J. Phys. Chem. C 120, 22202 (2016)

Q. Wang, Y.F. Ruan, W.W. Zhao, P. Lin, J.J. Xu, H.Y. Chen, Anal. Chem. 90, 3759 (2018)

Z.K. Heiba, M.B. Mohamed, Appl. Phys. A 124(6), 446 (2018)

S.K. Han, C. Gu, S. Zhao, S. Xu, M. Gong, Z. Li, S.H. Yu, J. Am. Chem. Soc. 138, 12913 (2016)

H. Dang, Z. Cheng, W. Yang, W. Chen, W. Huang, B. Li, Z. Shi, Y. Qiu, X. Dong, H. Fan, J. Alloys Compd. 709, 422 (2017)

H. Zhu, T. Lian, Energy Environ. Sci. 5, 9406 (2012)

X. Deng, C. Wang, H. Yang, M. Shao, S. Zhang, X. Wang, M. Ding, J. Huang, X. Xu, Sci. Rep. 7, 3877 (2017)

X. Yang, G. Lu, B. Wang, T. Wang, Y. Wang, RSC Adv. 9, 25142 (2019)

A. Malathi, J. Madhavan, J. Nano Res. 48, 49 (2016)

A. Sjadhav, V.M. Bhuse, Bull. Mater. Sci. 42, 125 (2019)

I. Vamvasakis, A. Trapali, J. Miao, B. Liu, G.S. Armatas, Inorg. Chem. Front. 4, 433 (2017)

Z.K. Heiba, M.B. Mohamed, J. Inorg. Organomet. Polym Mater. 30(3), 879 (2020)

Z.K. Heiba, M.B. Mohamed, J.R. Plaisier, A.M. El-naggar, A.A. Albassam, Chin. J. Phys. (2020). https://doi.org/10.1016/j.cjph.2020.04.010

M.B. Mohamed, Z.K. Heiba, N.G. Imam, J. Mol. Struct. 1163, 442 (2018)

Z.K. Heiba, M.B. Mohamed, N.G. Imam, J. Mol. Struct. 1136, 321 (2017)

Z.K. Heiba, M.B. Mohamed, N.G. Imam, Ceram. Int. 41(10), 12930 (2015)

Z.K. Heiba, N.G. Imam, M.B. Mohamed, Mater. Sci. Semicond. Process. 34, 39 (2015)

M.B. Mohamed, Int. J. Appl. Ceram. Technol. 17(2), 823 (2020)

L. Lutterotti, Nucl. Inst. Methods Phys. Res. B. 268, 334 (2010)

J. Rodríguez-Carvajal, Phys. B (Amst. Neth.) 192, 55 (1993)

T.P. Martin, H. Schaber, Spectrochem. Acta A 38, 655 (1982)

Y. Wang, L. Zhang, H. Jiu, N. Lia, Y. Sun, Appl. Surf. Sci. 303, 54 (2014)

T.P. Martin, H. Schaber, Spectmchim. Acta A 38(6), 655 (1982)

M.N. Kalasad, M.K. Rabinal, B.G. Mulimani, G.S. Avadhani, Semicond. Sci. Technol. 23(045009), 1 (2008)

G.T. Rao, R.J. Stella, B. Babu, K. Ravindranadh, C.V. Reddy, J. Shim, R.V.S.S.N. Ravikumar, Mater. Sci. Eng., B 201, 72 (2015)

R. Devi, P. Purkayastha, P.K. Kalita, B.K. Sarma, Bull. Mater. Sci. 30(2), 123 (2007)

R. Seoudi, A.B. El-Bailly, W. Eisa, A.A. Shabaka, S.I. Soliman, R.K. Abd El Hamid, R.A. Ramadan, J. Appl. Sci. Res. 8(2), 658 (2012)

S.C. Yan, Z.S. Li, Z.G. Zou, Langmuir 25, 10397 (2009)

B.M. Palve, S.R. Jadkar, H.M. Pathan, J. Mater. Sci.: Mater. Electron. 27, 11783 (2016)

C. Feng, X. Meng, X. Song, X. Feng, Y. Zhao, G. Liu, RSC Adv. 6, 110266–110273 (2016)

N. Sreelekha, K. Subramanyam, D.A. Reddy, G. Murali, K.R. Varma, R.P. Vijayalakshmi, Solid State Sci. 62, 71 (2016)

J. Tauc, Amorphous and Liquid Semiconductors (Plenum Press, London, 1974)

A.K. Sahoo, S.K. Srivastava, J. Nanopart. Res. 15, 1591 (2013)

H. Hu, J. Wang, C. Deng, C. Niu, H. Le, J. Mater. Sci. 53(20), 14250 (2018)

X. Li, Y. Li, F. Xie, W. Li, W. Li, M. Chen, Y. Zhao, RSC Adv. 5, 84465 (2015)

M. Mahanthappa, N. Kottam, S. Yellapp, Appl. Surf. Sci. 475, 828 (2019)

F. Cheng, Q. Xiang, RSC Adv. 6, 76269 (2016)

J. Zhang, F. Jiang, Phys. Lett. A 373, 3888 (2009)

M. Shkir, Z.R. Khan, M. Anis, S.S. Shaikh, S. AlFaify, Chin. J. Phys. 63, 51 (2020)

Z.K. Heiba, M.B. Mohamed, N.G. Imam, J. Alloy. Compd. 618, 280 (2015)

V. Krishnakumar, R. Ranjith, J. Jayaprakash, S. Boobas, J. Venkatesan, Mater. Sci. Mater. Electron. 28(18), 13990 (2017)

Y. Lie, W.K. Chim, H.P. Sun, G. Wilde, Appl. Phys. Lett. 86, 103106 (2005)

J.E.B. Katari, V. Colvin, A.P. Alivisatos, Chem. Phys. 98, 4109 (1994)

Y. Chen, Z. Qin, X. Wang, X. Guo, L. Guo, RSC Adv. 5, 18159 (2015)

Acknowledgements

The authors are grateful to the Deanship of Scientific Research, King Saud University, for funding through Vice Deanship of Scientific Research Chairs. The authors also would like to thank the MCX staff members for helping with the SR-XRPD measurements of the project No. 20190492 carried out at the MCX beam line of Elettra Synchrotron, Trieste, Italy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heiba, Z.K., Mohamed, M.B., Abdellatief, M. et al. Influence of alloying ratio in tailoring the structural and optical properties of (1 − x)CdS–xCuS nanocomposite. Appl. Phys. A 126, 518 (2020). https://doi.org/10.1007/s00339-020-03700-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03700-5